Method for drilling holes on printed circuit board

A printed circuit board, laser drilling technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of high machine cost, low carbon dioxide laser absorption rate, slow processing speed, etc., to achieve cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

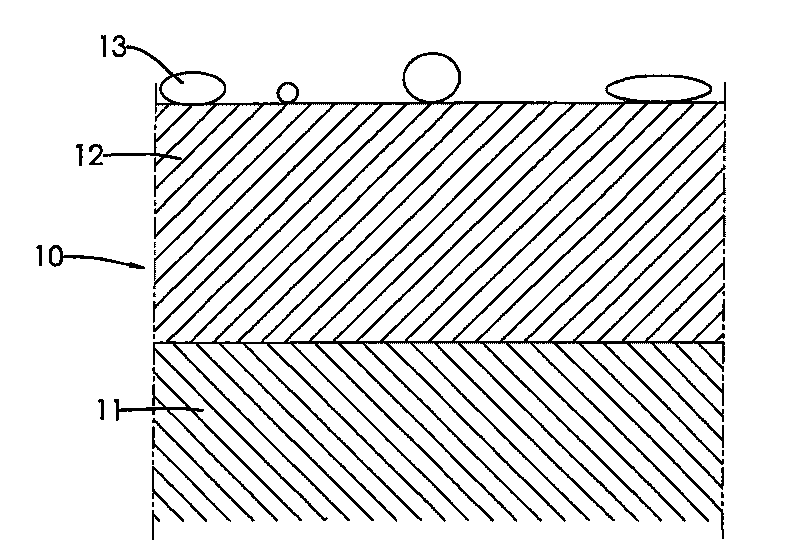

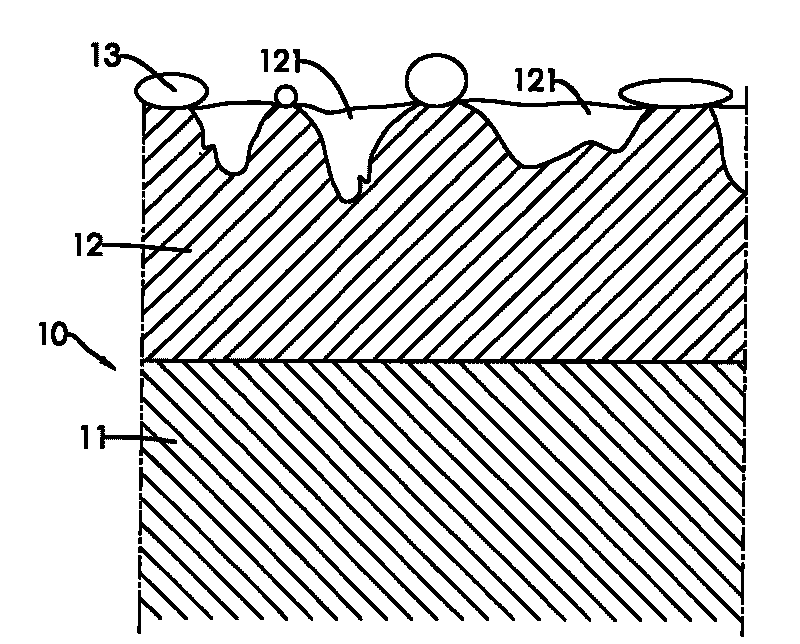

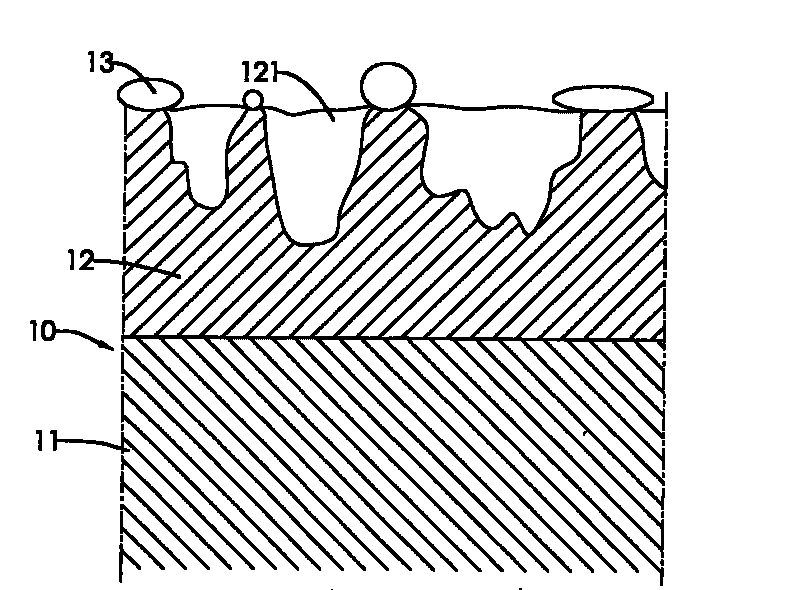

[0023] See figure 1 As shown, the present invention firstly provides a substrate 11 covered with copper foil 12 on one side of the board, the substrate 11 is made of insulating material, the insulating material can be resin, and the substrate 11 is on at least one side of the board Covered with copper foil 12, the thickness of the copper foil 12 can be between 12 and 18 μm, and then place the substrate 11 in an acid and alkali solution to remove oxides and grease on the surface of the copper foil 12, and then use a The cleaning solution is neutralized and cleaned. After cleaning, the copper foil 12 is chemically etched using an etching solution, which contains organic matter 13, sulfuric acid (H 2 SO 4 ), hydrogen peroxide (H 2 o 2 ) and an aqueous solution of copper ions, wherein sulfuric acid and hydrogen peroxide can corrode the copper foil, and their weight percentages can be 7 and 1.2 respectively, and the organic matter 13 can be uniformly dispersed and adsorbed on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com