Dielectric adjustable BST-MB two-phase compound microwave ceramic material and method for preparing same

A microwave ceramic and dielectric technology is applied in the field of BST-MB two-phase composite microwave ceramic materials and its preparation, and achieves the effects of large changes, widened application scope and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

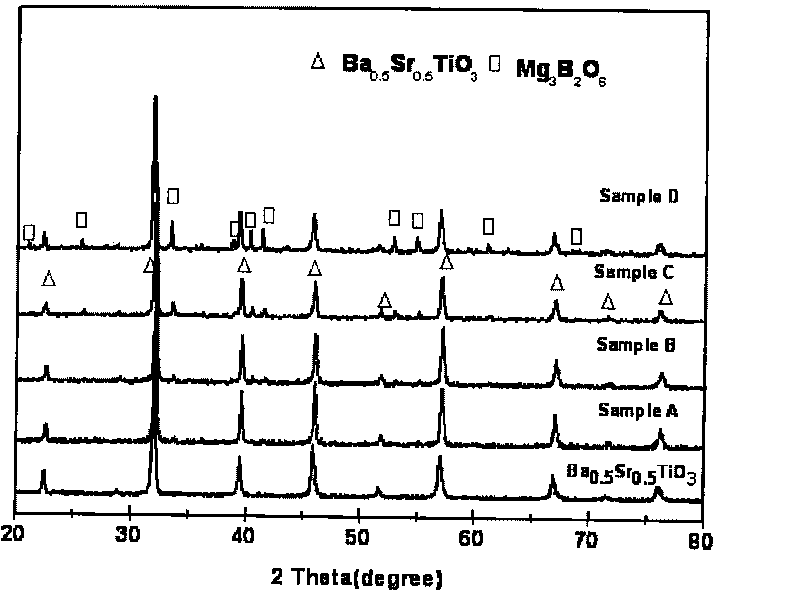

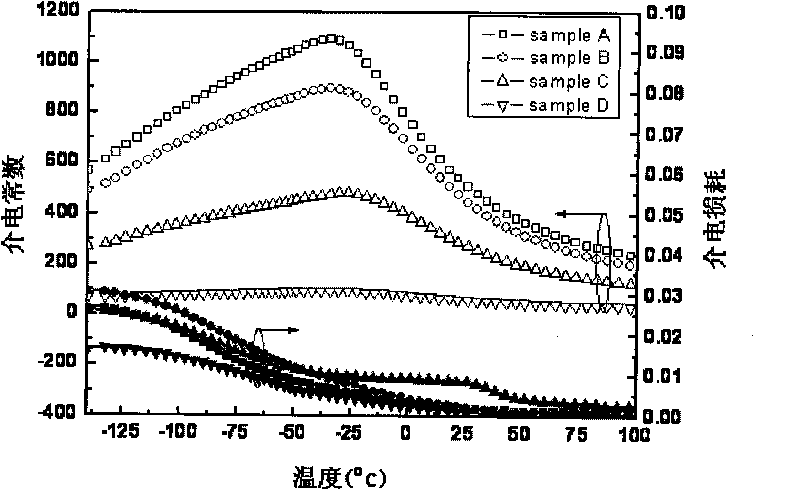

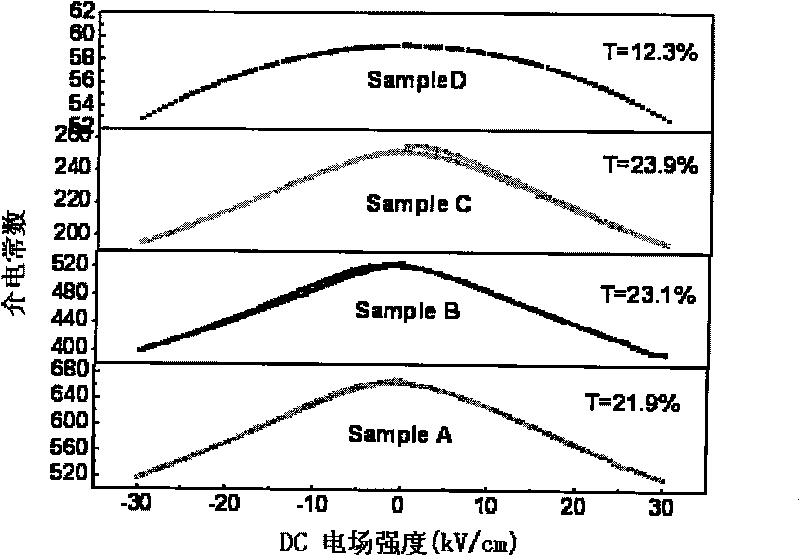

Method used

Image

Examples

Embodiment 6

[0056] Embodiment 6 prepares Ba 0.3 Sr 0.7 TiO 3 -Mg 3 B 2 o 6 Two-phase composite microwave ceramic materials:

[0057] (1) According to Ba 0.3 Sr 0.7 TiO 3 The stoichiometric ratio, weighed 42.023g BaTiO 3 and 77.157 g SrTiO 3 Put the powder into a nylon ball mill jar, add zirconia balls (the mass ratio of the zirconia balls to the ball mill is 1.2:1) and absolute ethanol (the mass ratio of the absolute ethanol to the ball mill is 1.5:1), and ball mill for 24 Hours, pre-calcined at 1100°C for 4 hours after the discharge was dried, and Ba 0.3 Sr 0.7 TiO 3 The powder is ready for use.

[0058] (2) Weigh 30.225g MgO, 31.070g H 3 BO 3 and 0.932 g of excess H 3 BO 3 Put the powder into a nylon ball mill jar, add zirconia balls (the mass ratio of the zirconia balls to the ball mill is 1.2:1) and absolute ethanol (the mass ratio of the absolute ethanol to the ball mill is 1.5:1), and ball mill for 24 Hours, pre-calcined at 1150°C for 4 hours after the discharge wa...

Embodiment 7

[0061] Embodiment 7 prepares Ba 0.7 Sr 0.3 TiO 3 -Mg 3 B 2 o 6 Two-phase composite microwave ceramic materials:

[0062] (3) According to Ba 0.7 Sr 0.3 TiO 3 The stoichiometric ratio, weigh 98.054g BaTiO 3 and 33.067 g SrTiO 3 Put the powder into a nylon ball mill jar, add zirconia balls (the mass ratio of the zirconia balls to the ball mill is 1.5:1) and deionized water (the mass ratio of the deionized water to the ball mill is 3.0:1), and mill for 24 Hours, after the discharge is dried, it is pre-calcined at 1100°C for 2 hours, and Ba 0.7 Sr 0.3 TiO 3 The powder is ready for use.

[0063] (4) Weigh 30.225g MgO, 31.070g H 3 BO 3 and 0.932 g of excess H 3 BO 3 Put the powder in a nylon ball mill jar, add zirconia balls, add absolute ethanol or deionized water, ball mill for 24 hours, and pre-calcine at 1150°C for 4 hours after discharging the material, and get Mg after grinding 3 B 2 o 6 The powder is ready for use.

[0064] According to Ba 0.7 Sr 0.3 Ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com