Method for preparing conductive composite atomic oxygen protective coating ITO/MgF2

A composite atom and protective coating technology, applied in the aerospace field, can solve the problems of easy occurrence of micro-cracks, easy accumulation of static electricity, atomic oxygen erosion, etc., and achieves the effects of good protection performance, good flexibility, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

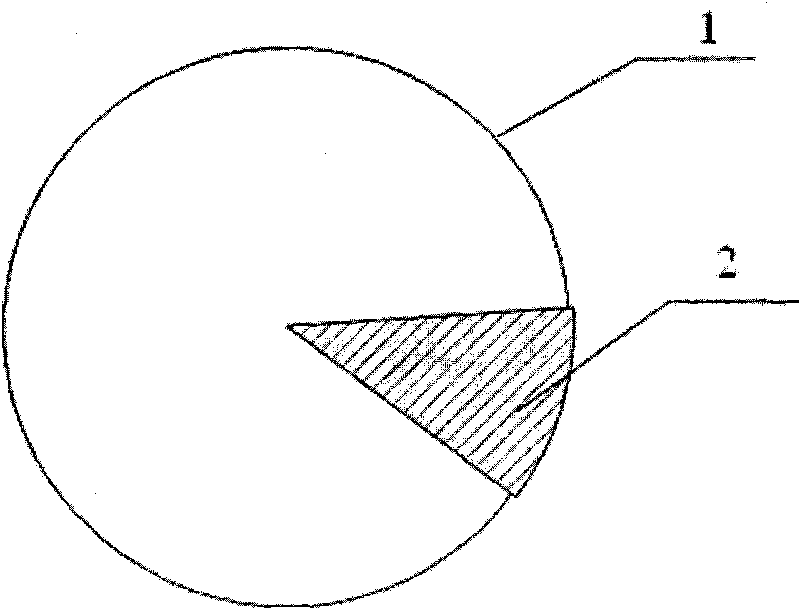

[0021] (1) Preparation diameter is 100mm, thickness is 10mm, In 2 O 3 The mole percentage of 91%, SnO 2 An ITO target with a molar percentage of 9%;

[0022] (2) Prepare 4 pieces of MgF with a diameter of 100mm and a fan angle of 20° 2 Sheet material, MgF 2 The purity of 99.9%;

[0023] (3) MgF 2 The sheet material is evenly pasted on the ITO target;

[0024] (4) The ITO / MgF prepared in (3) 2 The composite target is installed on the target base of the magnetron sputtering equipment, and the magnetron sputtering equipment is evacuated to 2×10 -3 Pa, then add Ar gas, turn on the power of the magnetron sputtering target, the target surface will produce glow discharge, and the Ar ion current will affect the ITO / MgF 2 The target is bombarded, and ITO and MgF are sputtered from the target surface 2 , Deposited on Kapton substrate to get ITO / MgF 2 Conductive composite atomic oxygen protective coating; deposition discharge power is 100W, discharge pressure is 5×10 -1 Pa, the deposition time i...

Embodiment 2

[0028] (1) Preparation diameter is 100mm, thickness is 10mm, In 2 O 3 The mole percentage of 91%, SnO 2 An ITO target with a molar percentage of 9%;

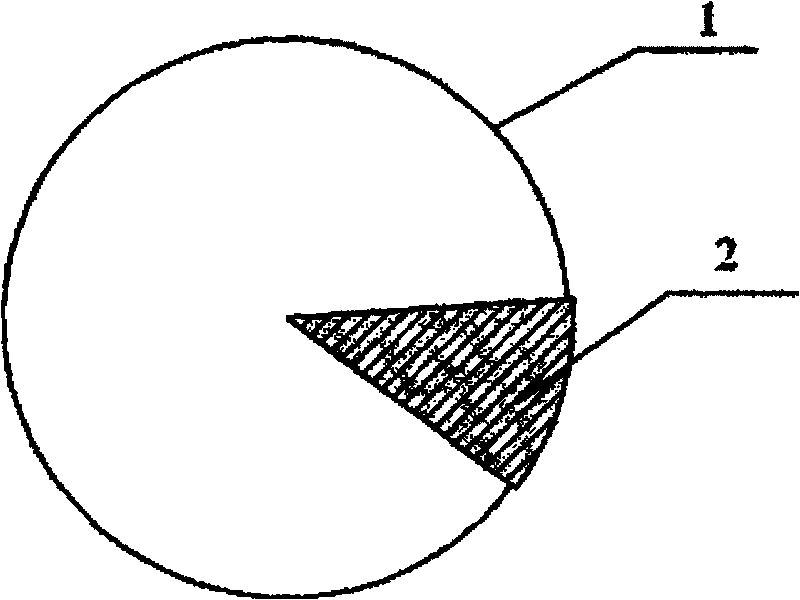

[0029] (2) Prepare 6 pieces of MgF with a diameter of 100mm and a sector angle of 15° 2 Sheet material, MgF 2 The purity of 99.9%;

[0030] (3) MgF 2 The sheet material is evenly pasted on the ITO target;

[0031] (4) The ITO / MgF prepared in (3) 2 The composite target is installed on the target base of the magnetron sputtering equipment, and the magnetron sputtering equipment is evacuated to 2×10 -3 Pa, then add Ar gas, turn on the power of the magnetron sputtering target, the target surface will produce glow discharge, and the Ar ion current will affect the ITO / MgF 2 The target is bombarded, and ITO and MgF are sputtered from the target surface 2 , Deposited on Kapton substrate to get ITO / MgF 2 Conductive composite atomic oxygen protective coating; deposition discharge power is 120W, discharge pressure is 4×10 -1 Pa, deposition time is...

Embodiment 3

[0035] (1) Preparation diameter is 100mm, thickness is 10mm, In 2 O 3 The mole percentage of 91%, SnO 2 An ITO target with a molar percentage of 9%;

[0036] (2) Prepare 5 pieces of MgF with a diameter of 100mm and a fan angle of 20° 2 Sheet material, MgF 2 The purity of 99.9%;

[0037] (3) MgF 2 The sheet material is evenly pasted on the ITO target;

[0038] (4) The ITO / MgF prepared in (3) 2 The composite target is installed on the target base of the magnetron sputtering equipment, and the magnetron sputtering equipment is evacuated to 2×10 -3 Pa, then add Ar gas, turn on the power of the magnetron sputtering target, the target surface will produce glow discharge, and the Ar ion current will affect the ITO / MgF 2 The target is bombarded, and ITO and MgF are sputtered from the target surface 2 , Deposited on Kapton substrate to get ITO / MgF 2 Conductive composite atomic oxygen protective coating; deposition discharge power is 110W, discharge pressure is 4.5×10 -1 Pa, the deposition time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com