Silver plated fiber with anti-discoloration layer and manufacturing method thereof

A silver-plated fiber and anti-discoloration technology, which is applied in fiber treatment, coating, sputter plating, etc., can solve the problems that cannot include non-dissolving antibacterial fiber quantitative test standards, and achieve the effect of preventing discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

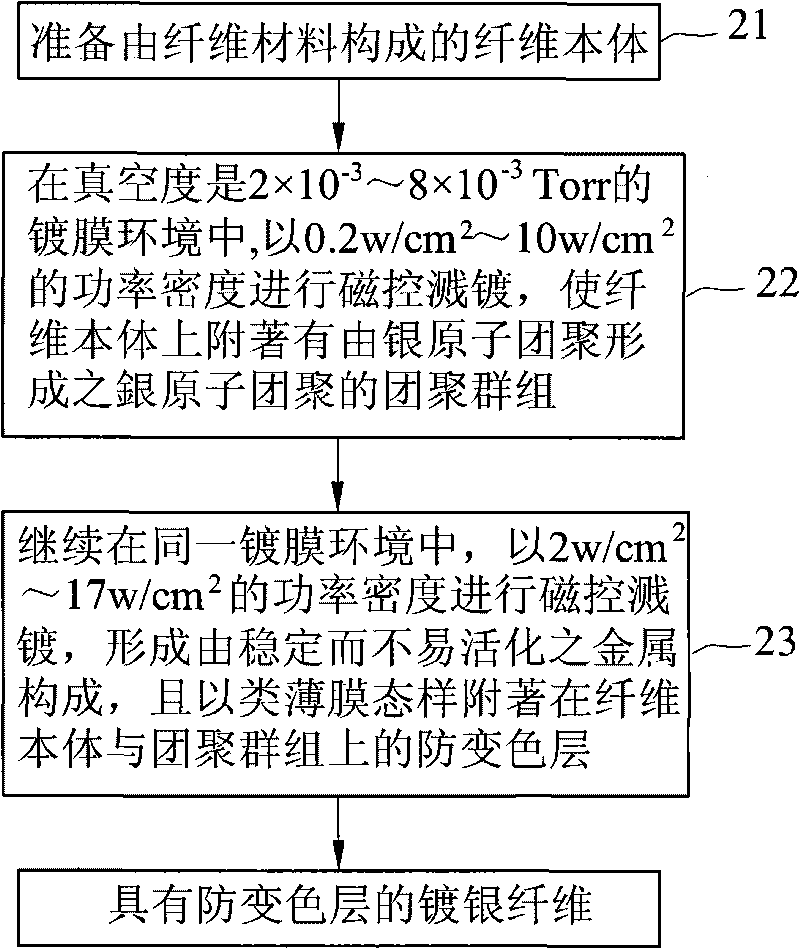

Method used

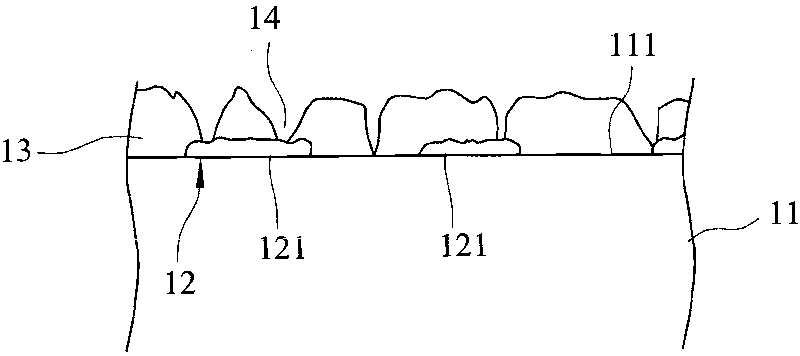

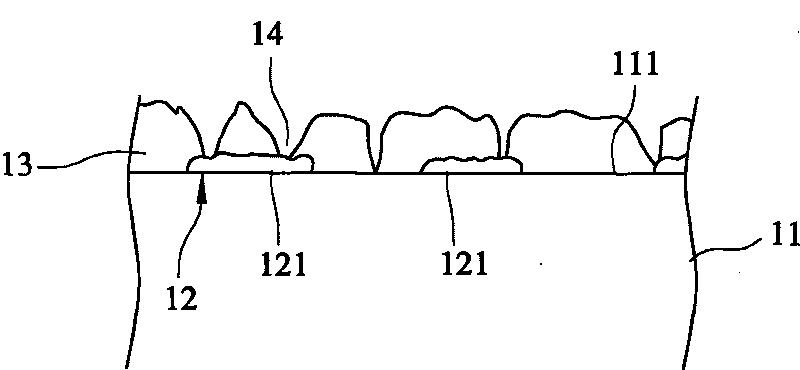

Image

Examples

experiment example 1 007

[0039] Experimental Example 1 2007 / 05 / 11; serial number TX42192 / 2007 / PL

[0040] (a) The fiber body is a 30g basis weight melt-blown non-woven fabric (white), and the silver atoms are agglomerated in a vacuum of 2×10 with argon gas -3 Torr sputtering environment at 0.3w / cm 2 It is formed by sputtering with high sputtering power, the content is about 100ppm, and the anti-tarnish layer is made of titanium and matched with 5w / cm 2 The sputtering power coating is formed, the thickness is

[0041] (b) The fiber body is 50 denier knitted POLYESTER woven fabric (blue), and the silver atom reunion is at a vacuum degree of 3.75×10 -3 Torr sputtering environment at 0.3w / cm 2 It is formed by sputtering with high sputtering power, the content is about 100ppm, and the anti-tarnish layer is made of titanium and matched with 5w / cm 2 The sputtering power coating is formed with a thickness of about

[0042] (a), (b) two kinds of silver-coated fibers are effective against Staphylococcu...

experiment example 2 007

[0043] Experimental Example 2 2007 / 11 / 24 Number: TXD0455 / 2007 / HH

[0044] The fiber body of this experimental example is a 30g basis weight melt-blown non-woven fabric (white), and the silver atoms are agglomerated at a vacuum degree of 6 × 10 -3 1.5w / cm in Torr's sputtering environment 2 It is formed by sputtering with high sputtering power, the content is about 300ppm, and the anti-tarnish layer is made of titanium and matched with 8w / cm 2 The sputtering power coating is formed with a thickness of about

[0045] The silver-plated fiber of this experimental example has a sterilizing rate of 99.9% for multidrug-resistant Staphylococcus aureus (MRSA, methicillinresistant Staphylococcus aureus), and has passed the quantitative test of AATCC100 (bacteria count determination method) in the United States, and has excellent antibacterial efficacy.

experiment example 3 008

[0046] Experimental Example 3 2008 / 01 / 03 Number: TXD1644 / 2007 / HH

[0047] The fiber body of this experimental example is a 30g basis weight melt-blown non-woven fabric (white), and the silver atoms are agglomerated at a vacuum degree of 8 × 10 -3 Torr sputtering environment at 0.5w / cm 2 It is formed by sputtering with high sputtering power, the content is about 200ppm, the anti-tarnish layer is made of titanium and matched with 8w / cm 2 The sputtering power coating is formed, the thickness is

[0048] The silver-plated fiber of this experimental example has a sterilizing rate of 99.9% against Staphylococcus aureus, and has passed the quantitative test of AATCC100 (bacteria count determination method) in the United States, and has excellent antibacterial efficacy.

[0049] Compared with the current antibacterial fiber, the present invention mainly proposes a new, dry magnetron sputtering method to make antibacterial silver-plated fiber, and the silver-plated fiber obtained b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com