Double-clutch speed changer integrated control module

A dual-clutch transmission, clutch control technology, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the complex design and manufacture of the transmission case, the inability to use miniature cars, and the increase in the volume of the transmission Large and other problems, to achieve the effect of reducing the difficulty of design and manufacturing, compact structure, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The integrated control module of the dual-clutch transmission of the present invention will be further described below in conjunction with the accompanying drawings.

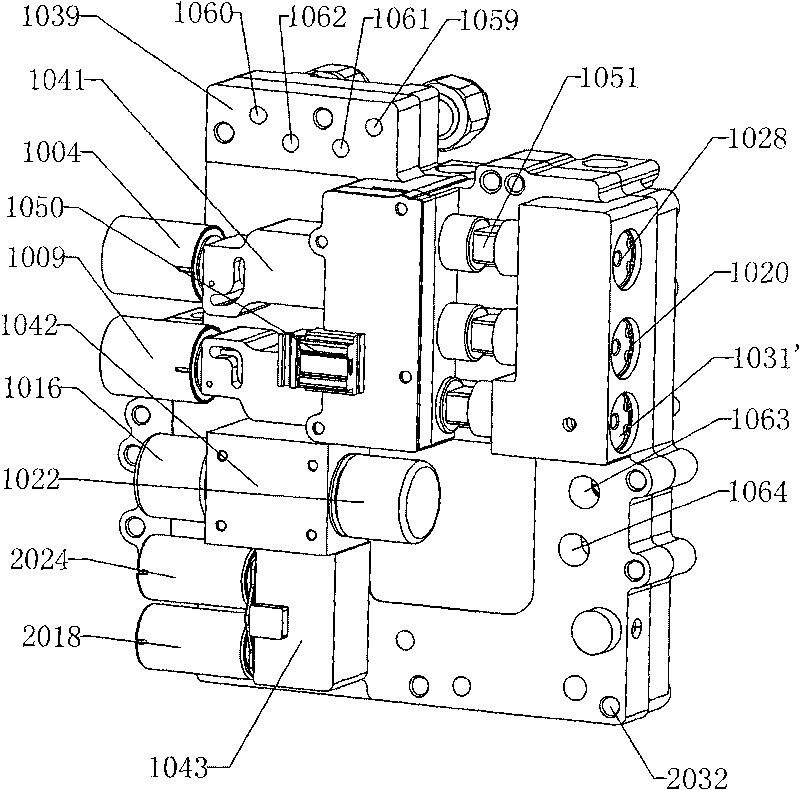

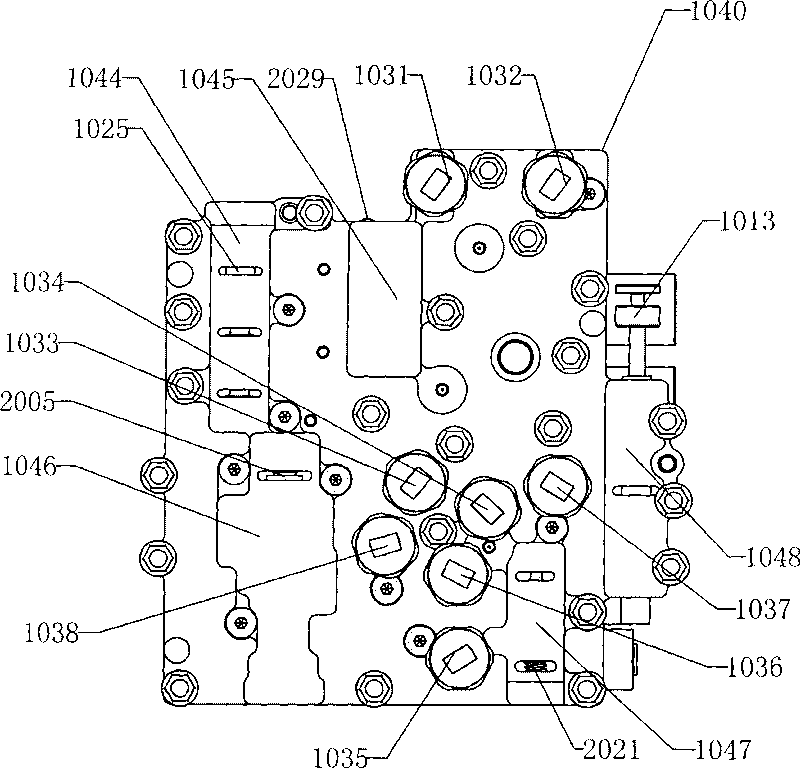

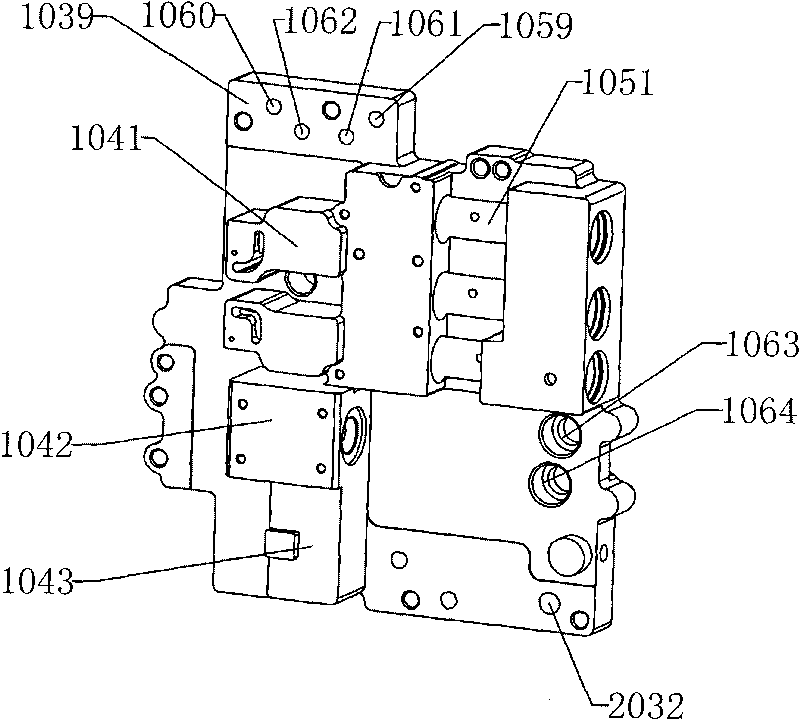

[0028] see figure 1 , figure 2 and Figure 9 , the integrated control module of the dual-clutch transmission of the present invention includes a hydraulic valve block connected by the front hydraulic valve block 1039 and the rear hydraulic valve block 1040 and a control module constituting the hydraulic control system of the dual-clutch transmission. The clutch control module 1054 for switching each clutch independently, the shift control module 1055 for driving the synchronizer shift of the transmission, the clutch cooling module 1056 for controlling the clutch coolant, and the control module for controlling the internal shaft coolant of the transmission The shafting cooling module 1057 and the main pressure regulating module 1058 used to regulate the pressure of the entire hydraulic system.

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com