Method for manufacturing winding wire

A manufacturing method and winding wire technology, applied in the field of enameled wire, can solve the problems of electronic transformer miniaturization, high frequency, large transformer, and low enameled wire voltage, so as to reduce leakage inductance and distributed capacitance, improve high frequency characteristics, The effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

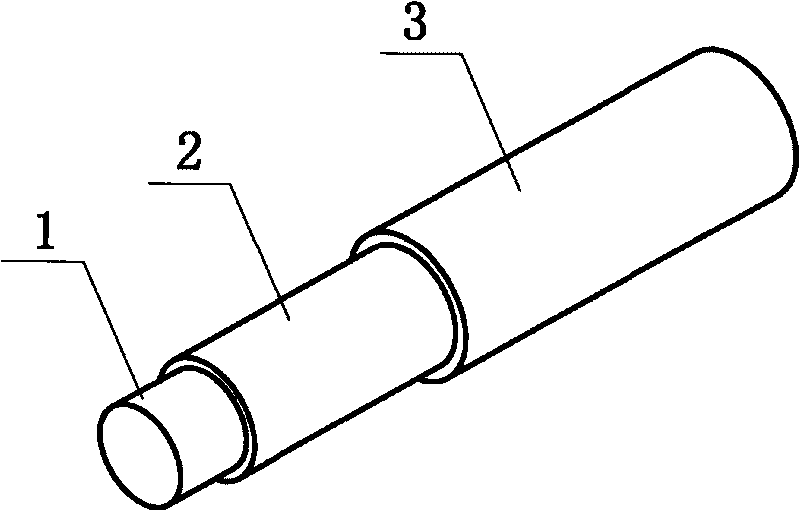

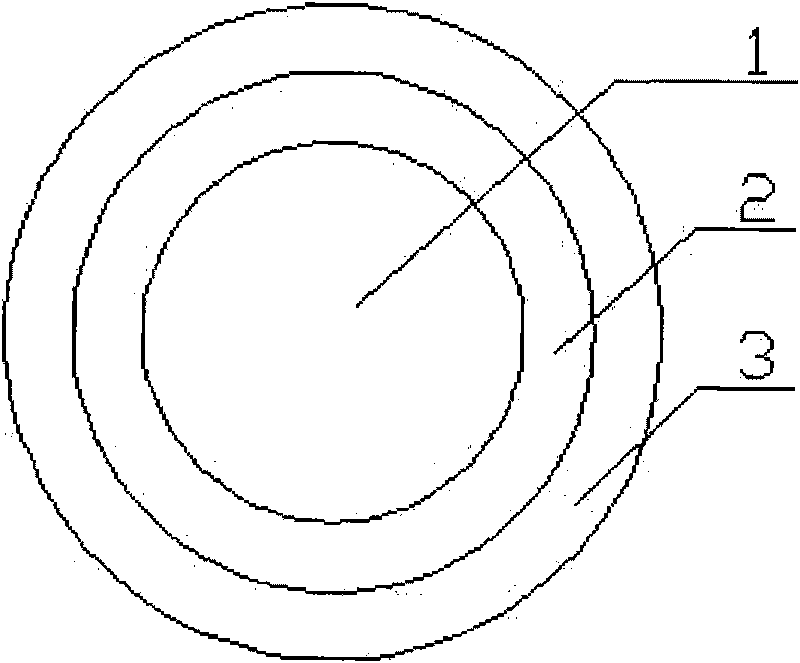

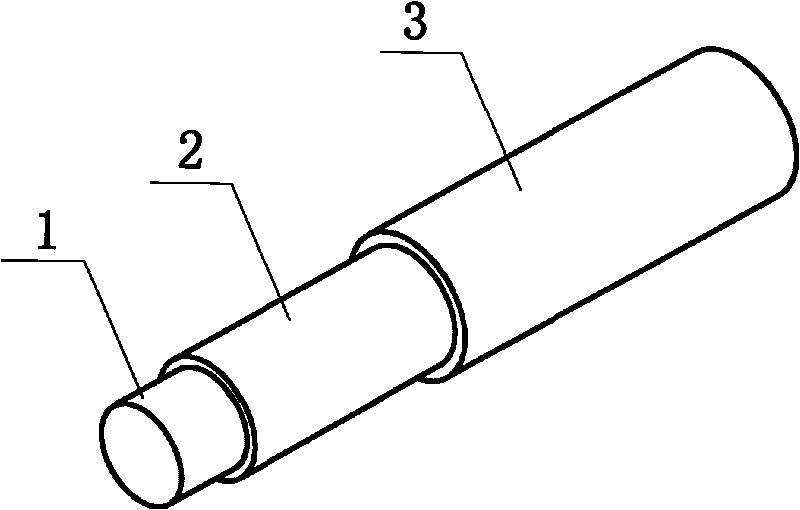

[0010] A winding wire manufacturing method, the method uses a Φ3mm copper rod to be thinned to Φ0.10-0.19mm by a wire drawing machine to make a copper conductor, and then annealed and painted to make an enameled wire, and then passed through a 20-type single-screw extruder to Polyester insulating resin is extruded on the outside of the enameled wire to obtain the winding wire.

[0011] The performance that the inventive method obtains for the winding wire of transformer is:

[0012] 1. Production specification range: 0.10~0.19mm;

[0013] 2. Temperature resistance class E (120°C) and B (130°C);

[0014] 3. It has excellent withstand voltage characteristics, the breakdown voltage is greater than 10kV, and has obtained the identification of basic insulation (test voltage 1500Vrms, 1min);

[0015] 4. It can be directly welded without peeling off the outer layer, and the solderability is 420℃≤2S;

[0016] 5. Excellent wear resistance and surface smoothness, static friction coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com