High-field superconducting magnet system with wide separation gaps

A technology for superconducting magnets and high magnetic fields, applied in the direction of superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problem of insufficient separation gap between superconducting magnets, achieve simple structure, reduce distance, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

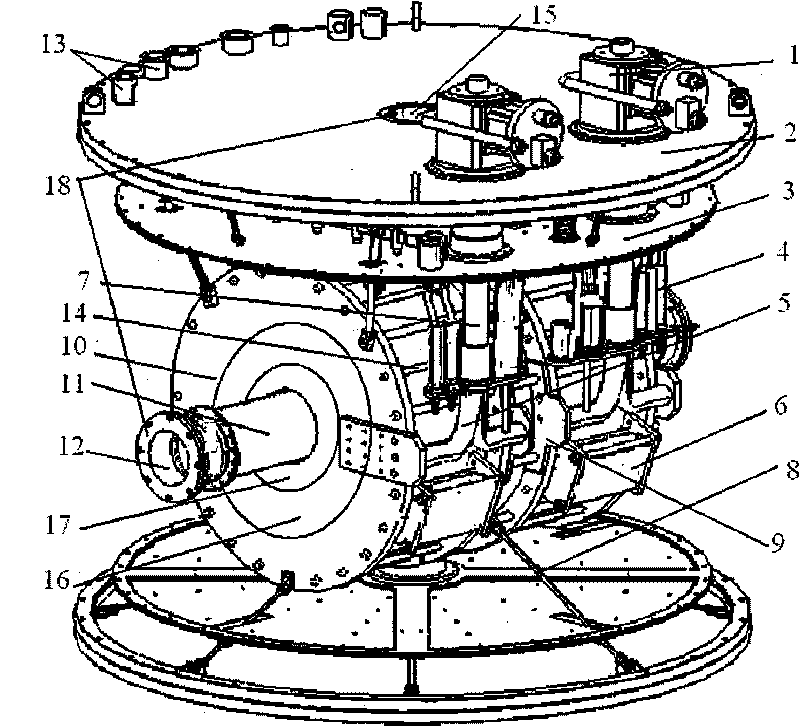

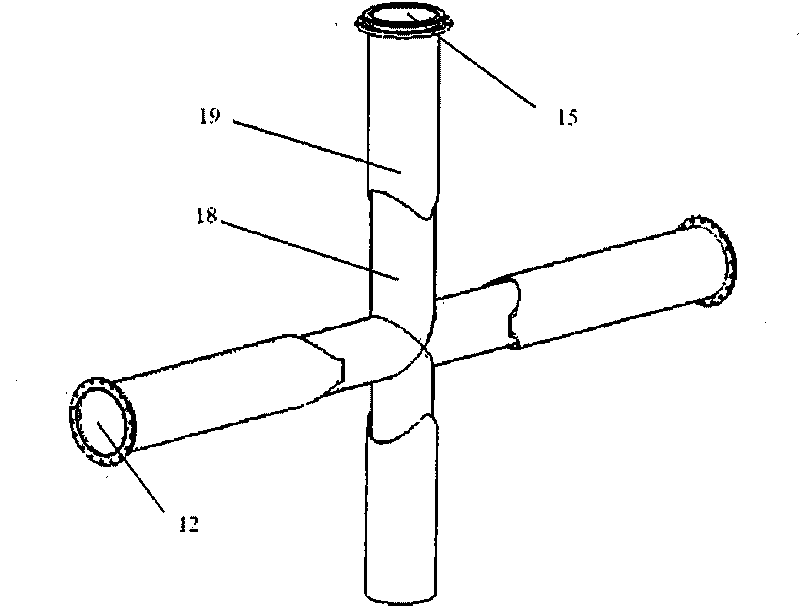

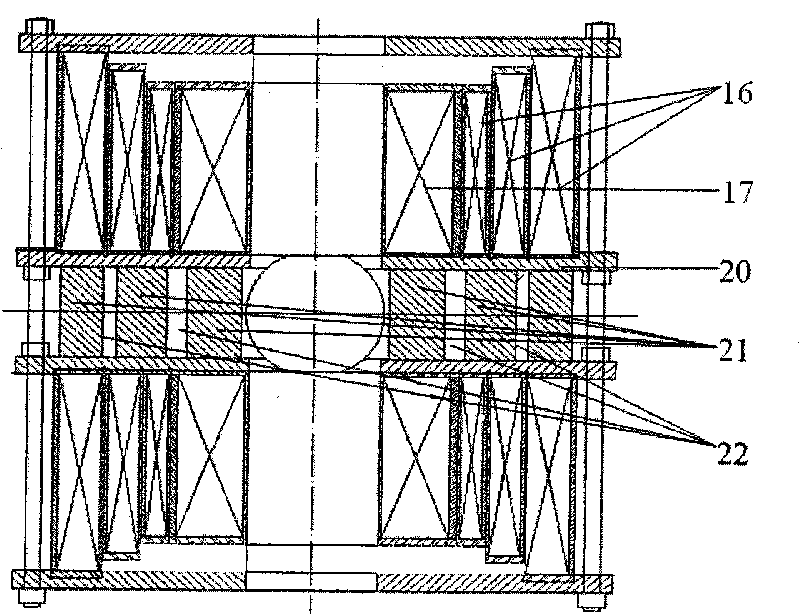

[0020] Such as figure 1 As shown, the refrigerator 1 is fixed on the flange 2 of the cryogenic container, the primary cold head of the refrigerator 1 cools the cold screen 3 of the cryogenic container, and the secondary cold head of the refrigerator 1 cools the low-temperature superconducting coil 16 and the high-temperature superconducting coil 17. The low temperature superconducting coil 16 and the high temperature superconducting coil 17 are supported and fixed together by the tie rod 14 . The low-temperature superconducting coil 16 and the high-temperature superconducting coil 17 are connected to the cryogenic container flange 2 through the support rod 8 and the cold shield 3, and the low-temperature superconducting coil 16 and the high-temperature superconducting coil 17 are integrally supported inside the cryogenic container. The therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com