Method and device for treating corruptibility waste

A treatment method and technology for waste, applied in the field of treatment of corrupt waste, can solve problems such as low efficiency, harm to crop growth, and odor generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

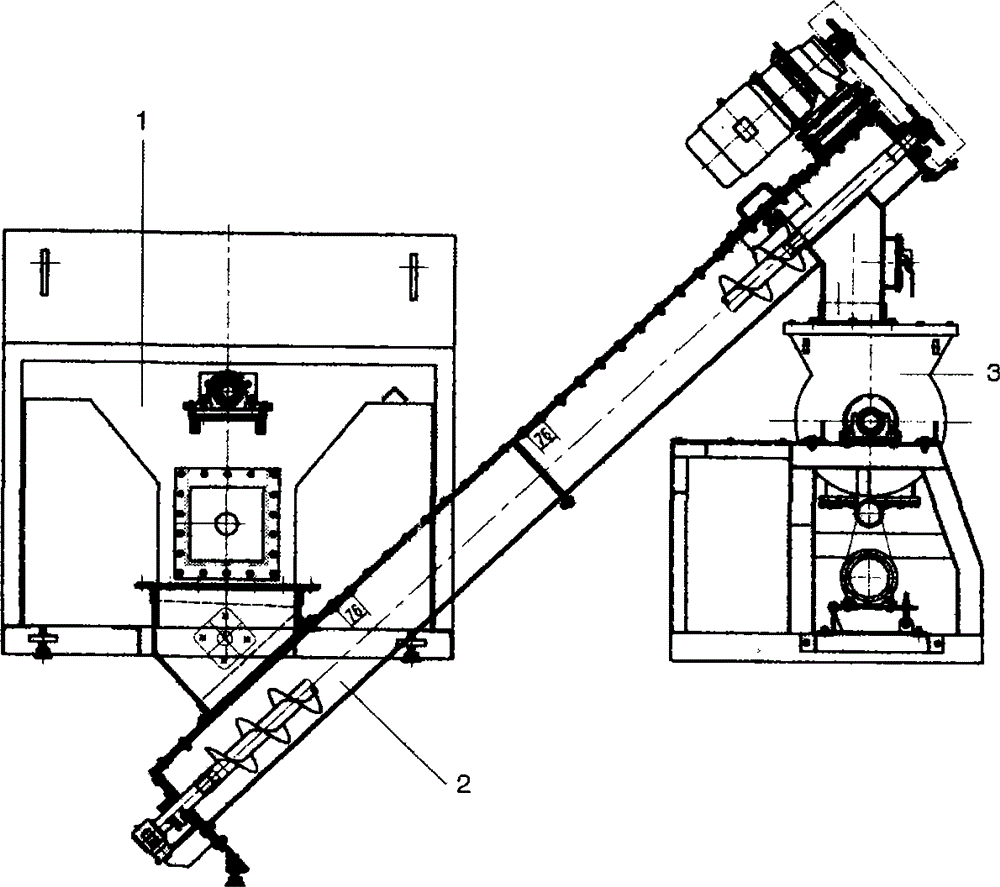

[0014] Put 60 kg of chicken manure into the raw meal pretreatment system 1, stir to remove sundries such as chicken feathers, ribbon-shaped sundries, etc. through the stirring claw, and use the screw pusher shaft of the raw meal elevator 2 to put the processed product into the reactor 4 The mixing chamber is ready for use; put 3 kg of active additive calcium oxide into the auxiliary material batching system 3, and put it into the mixing chamber through the screw pusher shaft for mixing and stirring, so that the oxygen in the air, calcium oxide, and waste are evenly mixed.

[0015] The exhaust gas generated in the stirring mixing reactor is sequentially introduced into two oxidation treatment devices 6 storing chlorine dioxide through the exhaust fan. The first device first performs deodorization and purification pretreatment, and the second device evolves the tail gas again, and finally The purified gas is vented to the atmosphere.

[0016] The stirred product is conveyed out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com