Purification technology and equipment of waste gas containing high concentration nitrogen oxide

A technology of nitrogen oxides and purification process, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problems of limited effect and difficult to meet the treatment requirements, and achieve simple operation, small footprint and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

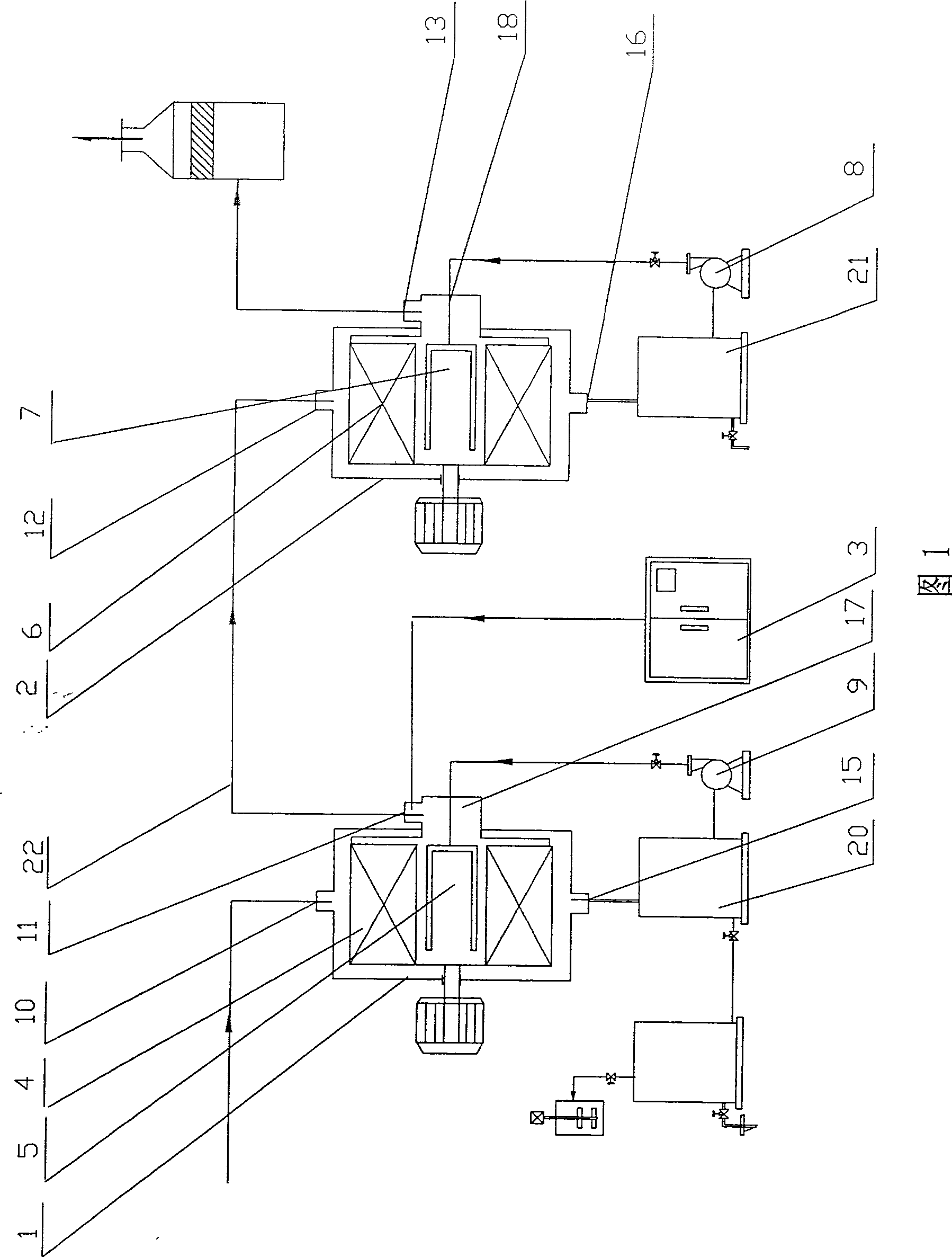

[0052] Embodiment 1 processing capacity is 700m 3 / h: The import concentration is 18000mg / m 3 The gunpowder smoke gas is collected by the gas collecting hood under the action of the induced draft fan, and enters the rotary packing bed 1 from the gas inlet 10, and diffuses into the rotary packing 4 under the action of the pressure difference, and the rotating packing speed is adjusted to 2400rpm. Concentration is that the dilute nitric acid solution of 10% is sent to the liquid distributor 5 of the first rotary packed bed 1 by circulation pump 9 from circulation tank 20 and is sprayed to packing inner side, and gas-liquid ratio is 1 / 50 (unit / liter), gas Contact and absorb the liquid countercurrently in the filler to remove nitrogen dioxide and part of nitrogen monoxide. Absorption liquid recovery treatment, the gas after the first absorption treatment is mixed with the ozone generated by the ozone generator 3 in the cavity of the outlet 11, and the NO in the gas is oxidized to...

Embodiment 2

[0054] The processing capacity is 2000m 3 / h; import concentration is about 10000mg / m 3 The concentration of gunpowder smoke gas is collected by the gas collecting hood under the action of the induced draft fan, and then enters the first rotating packed bed 1 through the air inlet 10, and the circulation pump 9 passes the sodium carbonate solution with a concentration of 15% in the first circulation tank 20 through the liquid inlet. The port 17 is driven into the liquid distributor 5 and enters the inner side of the rotary packing 4, and reacts with the gas from the gas inlet in the rotary packing to remove part of the NO 2 , the rotational speed of the rotary packing is 2000rpm, and the liquid-gas ratio is 1 / 50 (unit / liter). After the absorbed gas is discharged from the exhaust port 11, it enters the lower part of an oxidation tank, and undergoes an oxidation reaction with the hydrogen peroxide solution (0.2M) in the tank to oxidize NO in the gas to NO 2 , and then discharg...

Embodiment 3

[0056] The processing capacity is 2000m 3 / h; import concentration is about 10000mg / m 3 After being collected by the gas collection hood under the action of the induced draft fan, the gunpowder smoke gas with high concentration enters the first rotating packed bed 1 through the air inlet 10, and absorbs and reacts with the sodium hydroxide solution entering the rotating packing to remove part of the NO. 2 , the absorbed gas is mixed and reacted with the oxygen from the oxygen generator in the communication line 2, and the remaining NO in it is oxidized to NO 2 , and then enter the second rotating packed bed 2 through the air inlet 12, and carry out absorption reaction with the acidic urea absorption liquid in the rotating packing 6. The rotary packing speed is 1200rpm, and the liquid-gas ratio is 1 / 100 (unit / liter). The absorption temperature is 20°C, the absorption pressure is 1atm, and the gas meets the first-level emission standard of GBI6297-1996.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com