Miscanthus floridulus stalk leaf removing and surface layer processing device and method

A technology of surface treatment and five-section awn, which is applied in the direction of plant material machining, mechanical equipment, etc., can solve the problems of inapplicability, achieve the effect of developed root system, strong regeneration ability, and reduce ecological hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

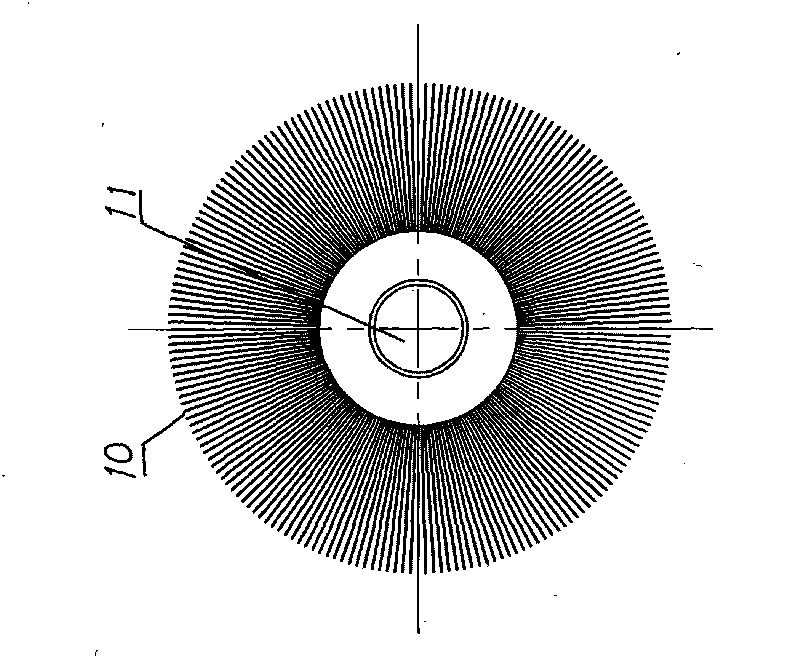

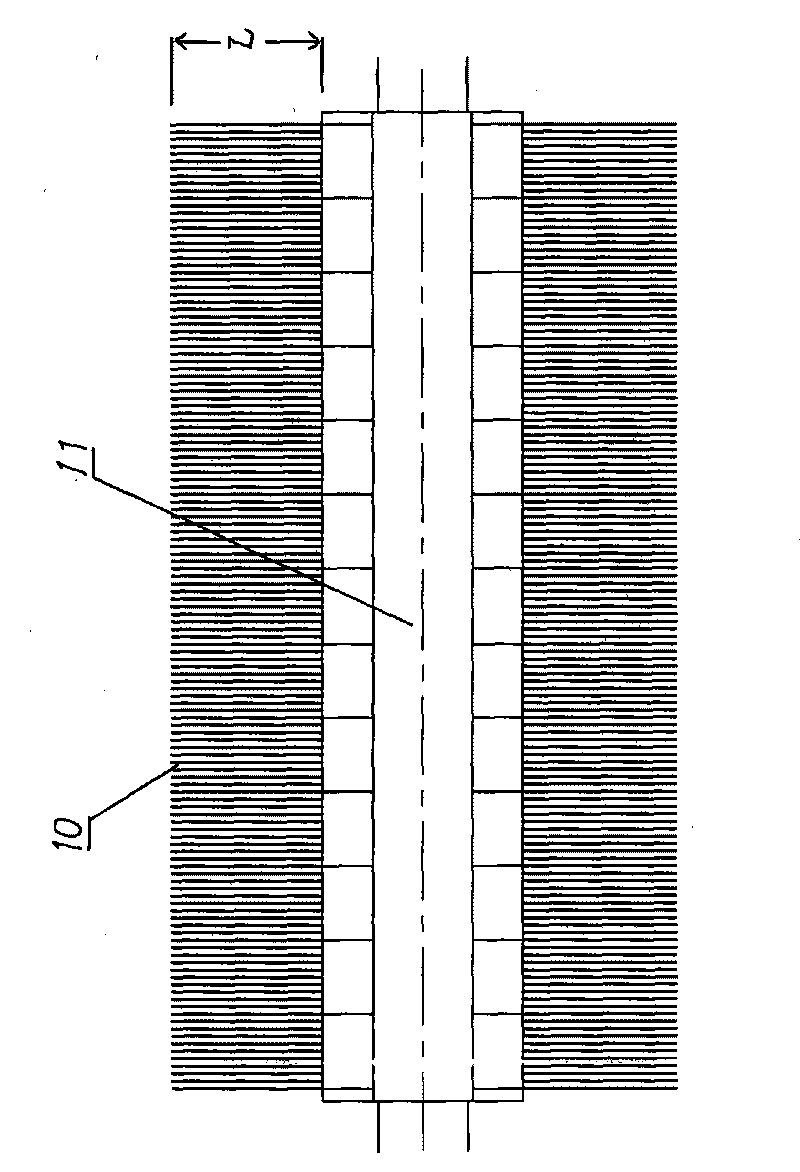

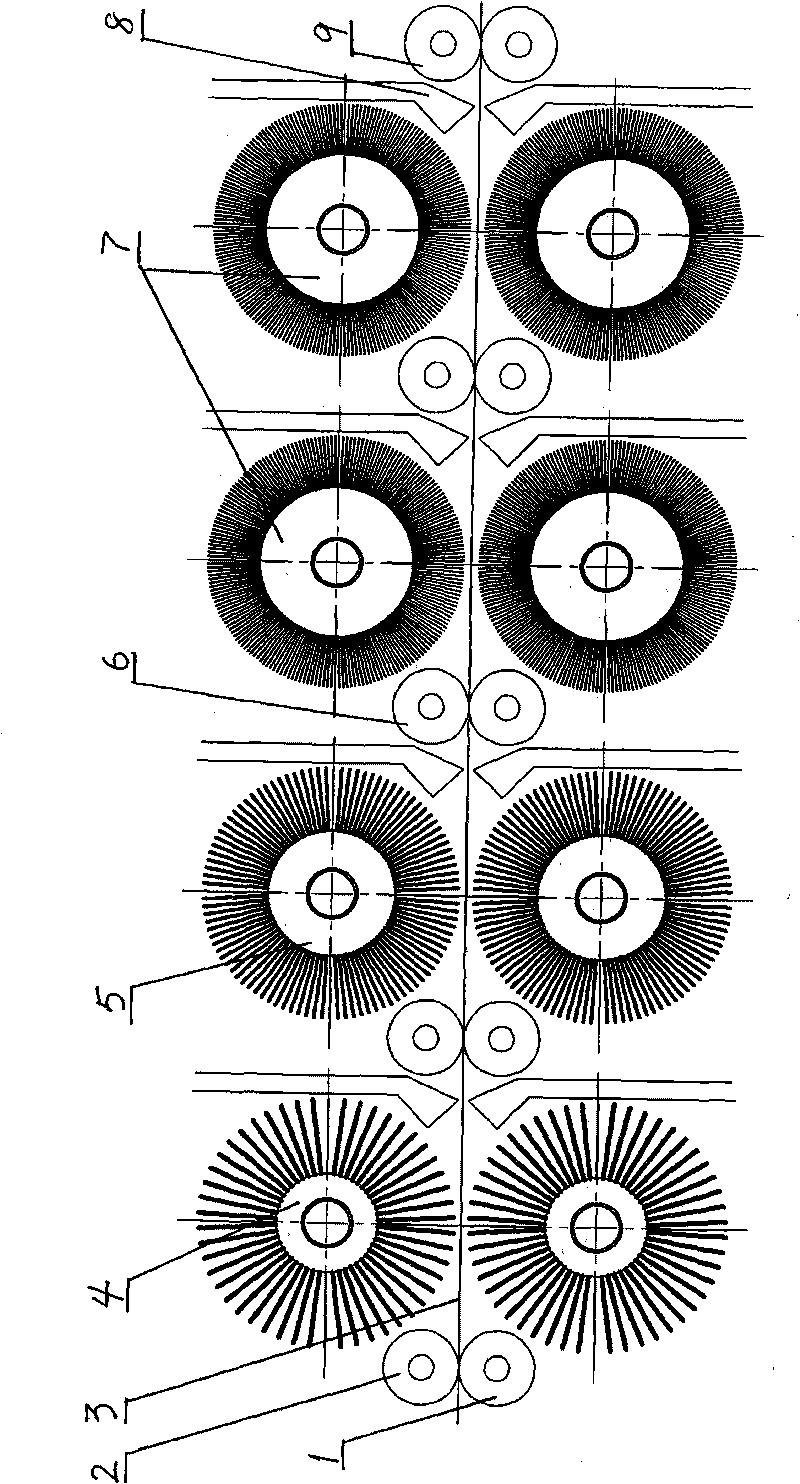

[0016] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings: the feeding roller and a single steel brush plate can be purchased from a hardware store or a mechanical parts store, and the steel brush roll can be stacked by multiple steel brush plates on their own and fitted with a roller shaft made. The installation of motor, vacuum pump, sprocket and chain and the whole device all belong to conventional technology and will not be described in detail. The elastic devices at the two ends of the roller shaft 11 of each roller should use low-cost reeds or coil springs, and the center point of the working roller surface of each pair of adjacent feeding rollers 6, 9 to the center of the working roller surface of the steel brush roller 4, 5, 7 The distance between the points should be less than 400mm, and there can be independent worktables between them, that is to say, there is no worktabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com