Inorganic nano-silver mildew-proof antibacterial healthy decorative veneer and manufacturing method thereof

An inorganic nanometer and manufacturing method technology, applied in the field of decorative veneer wood-based panels and their manufacturing, can solve the problems of heat resistance, poor durability, increased air pollution sources, air quality deterioration, etc., achieve stable performance, improve indoor air quality, fine particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

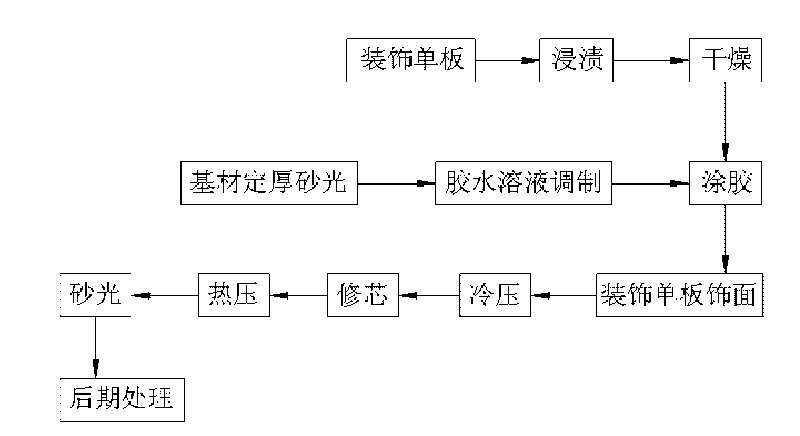

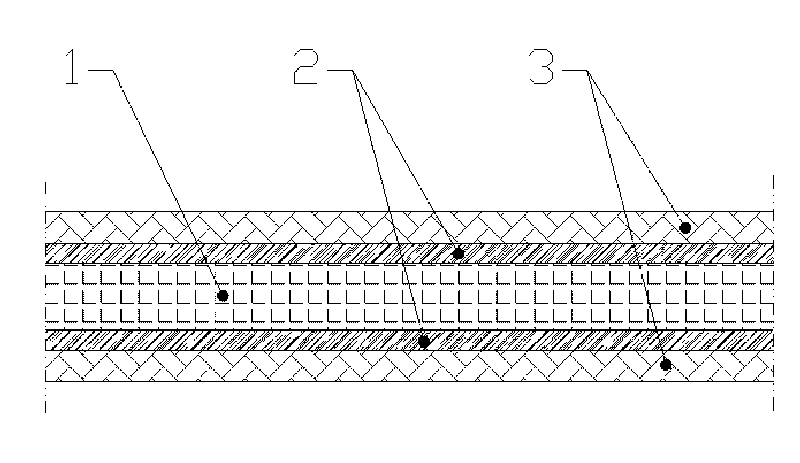

[0034] (1) Sand the 3mm thick miscellaneous wood plywood to a certain thickness, and use it as the base material for later use.

[0035] (2) Immerse the 0.2mm thick natural red oak decorative veneer in the pre-prepared inorganic nano-silver aqueous solution. The concentration of nano silver in this solution is 50ppm, and the content of acrylic resin in the solution is 1%. After the decorative veneer is dipped, dry it and set it aside.

[0036] (3) The glue ratio is: adhesive 100kg, flour 20±2kg, inorganic nano-silver aqueous solution 9g, ammonium chloride 1±0.1kg. The adhesive is modified urea-formaldehyde resin glue or phenolic resin glue.

[0037] (4) Paste the impregnated red oak decorative veneer on the glued miscellaneous wood plywood, and the amount of glue on one side is 80g / m 2 .

[0038] (5) After veneering, pre-pressing, hot-pressing, post-sanding and other processes are carried out to form an inorganic nano-silver anti-mold, anti-bacterial, healthy red oak decor...

Embodiment 2

[0041] (1) Sand the 5mm thick medium density fiberboard to a certain thickness, and use it as a base material for later use.

[0042] (2) Immerse the 0.3mm thick white oak recombined decorative veneer in the pre-prepared inorganic nano-silver aqueous solution. The concentration of nano silver in this solution is 100ppm, and the content of acrylic resin in the solution is 6%. Dried after dipping, set aside.

[0043] (3) The glue ratio is: adhesive 100kg, flour 30±2kg, inorganic nano-silver aqueous solution 16g, ammonium chloride 1±0.1kg. The adhesive is modified urea-formaldehyde resin glue or melamine resin glue.

[0044] (4) Paste the impregnated red oak decorative veneer on the glued medium density fiberboard, the amount of glue on one side is 120g / m 2 .

[0045] (5) After veneering, pre-pressing, hot-pressing, post-sanding and other processes are carried out to form inorganic nano-silver anti-mildew, anti-bacterial, healthy white oak recombined decorative veneer. The p...

Embodiment 3

[0048] (1) Sand the 18mm thick particle board to a certain thickness, and use it as a base material for later use.

[0049] (2) Dip the 0.6mm thick red sandalwood dyed decorative veneer in the pre-prepared inorganic nano-silver aqueous solution. The concentration of nano silver in this solution is 150ppm, and the content of acrylic resin in the solution is 10%. Dried after dipping, set aside.

[0050] (3) The glue ratio is: adhesive 100kg, flour 45±2kg, inorganic nano-silver aqueous solution 22g, ammonium chloride 1±0.1kg. The adhesive is modified urea-formaldehyde resin glue or soybean adhesive.

[0051] (4) Paste the impregnated red sandalwood dyed decorative veneer on the glue-coated particle board, and the amount of glue on one side is 150g / m 2 .

[0052] (5) After veneering, pre-pressing, hot-pressing, post-sanding and other processes are carried out to form inorganic nano-silver anti-mildew, anti-bacterial, healthy white oak recombined decorative veneer. The pre-pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com