Lanthanum strontium manganate (LSMO) -based intelligent thermal-radiating material and preparation method thereof

A strontium lanthanum manganate and heat radiation technology, applied in the field of strontium lanthanum manganate based intelligent heat radiation materials and its preparation, variable heat radiation ceramic materials and preparation, can solve spalling and cracks, coarse grains, and firing shrinkage Large and other problems, to achieve the effect of improving uniformity and flatness, shortening sintering time, and reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

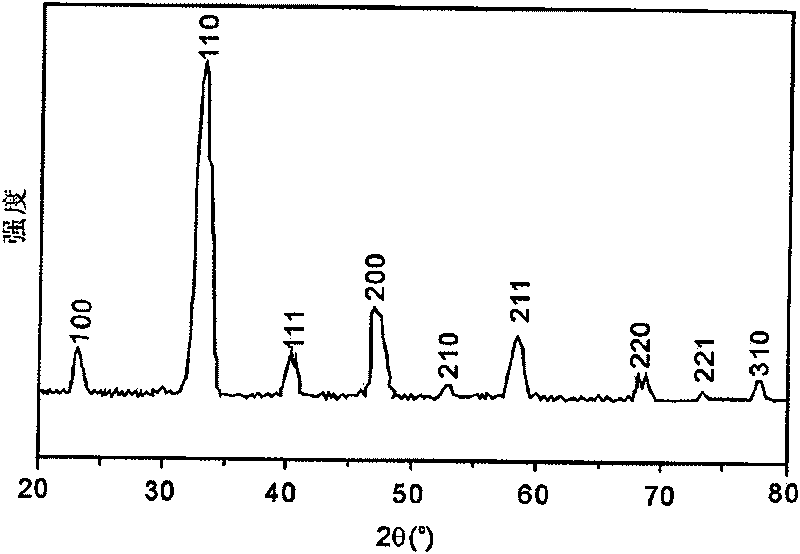

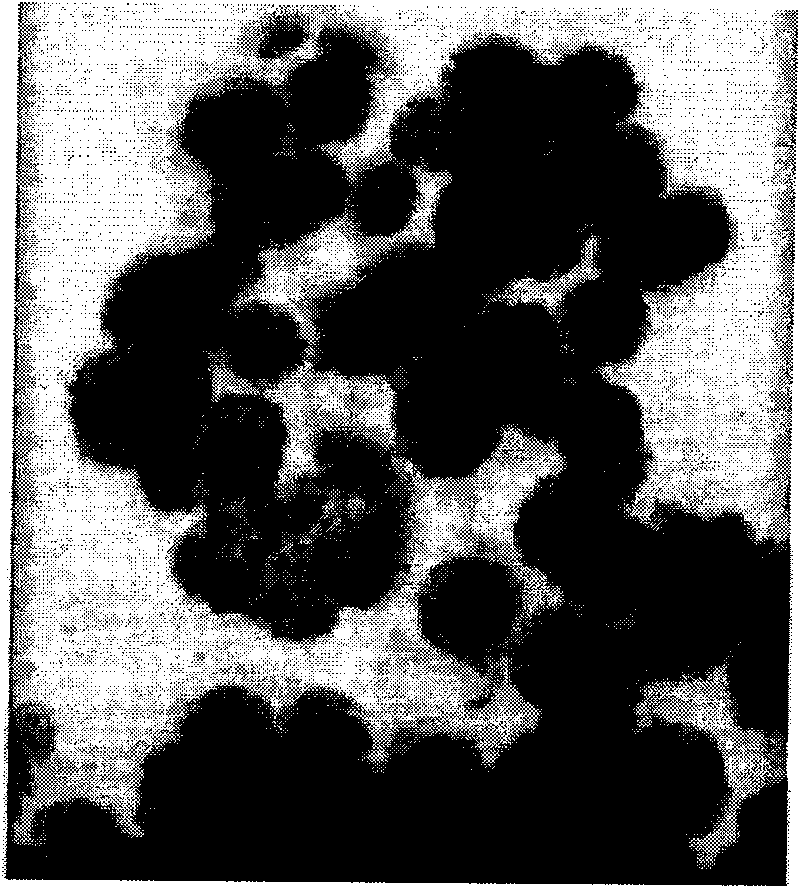

[0057] Press La 0.83 Sr 0.17 MnO 3 Chemical dosage ratio stock. Take 0.415 moles of La(NO 3 ) 3.6H 2 O, 0.085 mol Sr(NO 3 ) 2 and 0.5 mol Mn(NO 3 ) 2 .6H 2 O was dissolved in 1000 ml of deionized water, 1 vol.% of ammonium citrate, acrylamide and NN'-methacrylamide were added, and ultrasonically stirred at 80°C for 2 hours to form a transparent sol. The sol was placed in an oven for heat treatment at 150° C. for 4 hours to evaporate the moisture and obtain a xerogel. After the above xerogel was ground into fine powder in an agate bowl, it was degummed in a box-type resistance furnace at 350°C for 2.5h and calcined at 950°C for 1h to obtain La 0.83 Sr 0.17 MnO 3 Powder, the XRD analysis results and TEM morphology of the powder are as follows: Figure 1-a and Figure 1-b shown. It can be seen from the figure that the powder has a single-phase perovskite structure, and the particle size of a single crystal is 60nm.

[0058] La 0.83 Sr 0.17 MnO 3 Ceramic powder ...

Embodiment 2

[0060] Press La 0.84 Sr 0.16 MnO 3 Chemical dosage ratio stock. Take 0.42 moles of La(NO 3 ) 3 .6H 2 O, 0.08 mol Sr(NO 3 ) 2 and 0.5 mol Mn(NO 3 ) 2 .6H 2 O was dissolved in 1000 ml of deionized water, 5 vol.% of ammonium citrate, acrylamide and NN'-methacrylamide were added, and ultrasonically stirred at 80°C for 3 hours to form a transparent sol. The sol was placed in an oven and heat-treated at 100° C. for 5 hours to evaporate moisture and obtain a xerogel. After the above xerogel was ground into fine powder in an agate bowl, it was degummed in a box-type resistance furnace at 250°C for 2.5 hours and calcined at 800°C for 4 hours to obtain La 0.84 Sr 0.16 MnO 3 Powder.

[0061] La 0.84 Sr 0.16 MnO 3 Ceramic powder is mixed with PMAA (dispersant), PVA (bonding agent), PEG (plasticizer), Agitan280 (defoamer) and deionized water, wherein the volume percentage of ceramic powder is 50vol.%; The volume percentage of ionized water is 45%; various additives PMAA, ...

Embodiment 3

[0063] Press La 0.82 Sr 0.18 MnO 3 Chemical dosage ratio stock. Take 0.41 moles of La(NO 3 ) 3 .6H 2 O, 0.09 mol Sr(NO 3 ) 2 and 0.5 mol Mn(NO 3 ) 2 .6H 2 O was dissolved in 1000 ml of deionized water, 3 vol.% of ammonium citrate, acrylamide and NN'-methacrylamide were added, and ultrasonically stirred at 80°C for 1 hour to form a transparent sol. The sol was placed in an oven for heat treatment at 150° C. for 2 hours to volatilize the water and obtain a xerogel. After the above xerogel was ground into fine powder in an agate bowl, it was degummed in a box-type resistance furnace at 400°C for 2.5h and calcined at 1100°C for 1h to obtain La 0.82 Sr 0.18 MnO 3 Powder.

[0064] La 0.82 Sr 0.18 nO 3 Ceramic powder is mixed with PMAA (dispersant), PVA (bonding agent), PEG (plasticizer), Agitan280 (defoamer) and deionized water, wherein the volume percentage of ceramic powder is 35.5vol.%. The volume percentage of deionized water is 60vol.%; various additives PMAA,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com