Method for separating p-xylene crystal

A technology for the separation of p-xylene and crystallization, which is applied in crystallization purification/separation, organic chemistry, etc., can solve the problems of complex operation and high investment in xylene, and achieve the effect of cheap price, low investment and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

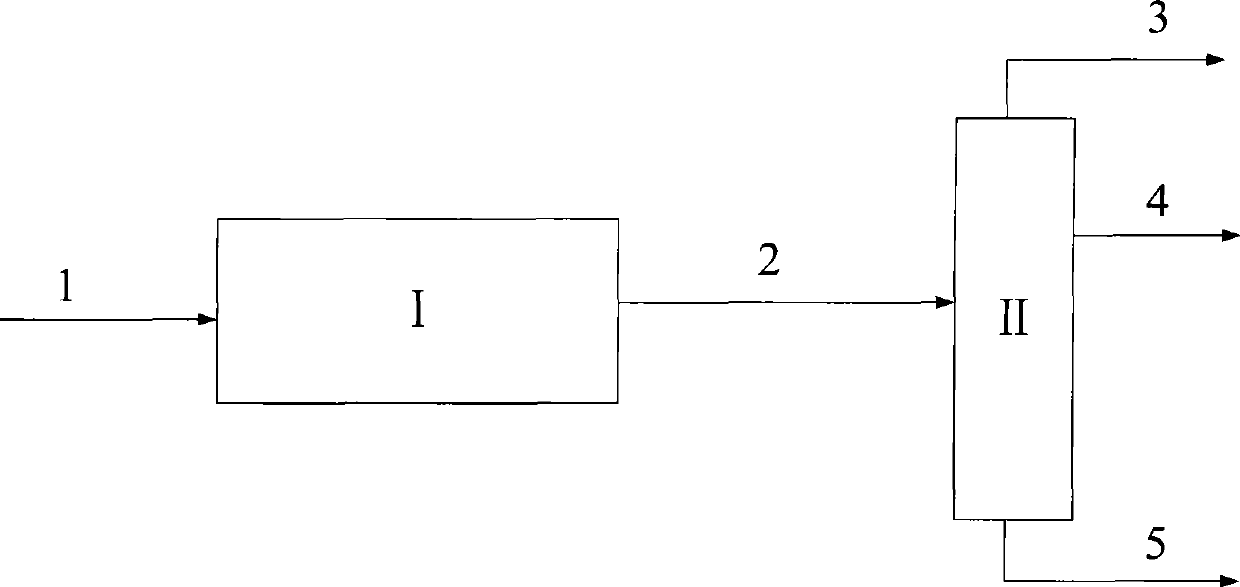

Image

Examples

Embodiment 1

[0015] The mixed xylene raw material is sent to the scraping wall crystallizer, and the crystallization temperature is -10°C to form a slurry. The slurry is sent to a simulated moving bed with 6 beds, and the flow is switched through a rotary valve to realize the simulated moving bed. Different functions, one of which is a filter bed, three are washing beds, one is a crystal melting bed, and one is a product output bed. The slurry was filtered, washed and crystals were purified in a simulated moving bed, and the washing liquid / crystal weight ratio was 0.2 to obtain pure p-xylene. After the test runs stably, the composition of each stream is shown in Table 1.

[0016] The composition (% by weight) of each stream among the table 1 embodiment 1

[0017] components raw material mother liquor Rinse pure p-xylene Ethylbenzene 5.0 11.2 5.8 0.0 m-xylene 5.0 11.4 6.2 0.1 O-xylene 10.0 22.6 12.6 0.1 p-xylene 80.0 54.8 75.4 99.8 ...

Embodiment 2

[0019] The mixed xylene raw material is sent to the stirring crystallizer, and the crystallization temperature is -80°C to form a slurry. The slurry is sent to a simulated moving bed with 10 beds, and the flow is switched through a rotary valve to realize the difference of the simulated moving bed Function, of which 1 bed is filter bed, 5 are washing beds, 3 are crystal melting beds, and 2 are product output beds. The slurry was filtered, washed and crystals were purified in a simulated moving bed, and the washing liquid / crystal weight ratio was 0.5 to obtain pure p-xylene. After the test runs stably, the composition of each stream is shown in Table 2.

[0020] The composition (% by weight) of each stream in the embodiment 2 of table 2

[0021] components raw material mother liquor Rinse pure p-xylene Ethylbenzene 15.0 33.5 14.4 0.1 m-xylene 10.0 19.7 8.7 0.0 O-xylene 15.0 34.1 13.4 0.1 p-xylene 60.0 12.7 63.5 99.8

Embodiment 3

[0023] The mixed xylene raw material is sent to the scraping wall crystallizer, and the crystallization temperature is 5°C to form a slurry. The slurry is sent to a simulated moving bed with 8 beds, and the flow is switched through a rotary valve to realize the difference of the simulated moving bed Function, of which 1 bed is filter bed, 3 are washing beds, 2 are crystal melting beds, and 2 are product output beds. The slurry was filtered, washed and crystals were purified in a simulated moving bed, and the washing liquid / crystal weight ratio was 0.05 to obtain pure p-xylene. After the test runs stably, the composition of each stream is shown in Table 3.

[0024] The composition (% by weight) of each stream among the table 3 embodiment 3

[0025] components raw material mother liquor Rinse pure p-xylene Ethylbenzene 2.0 7.2 3.7 0.1 m-xylene 1.0 3.5 1.8 0.0 O-xylene 2.0 7.6 3.3 0.1 p-xylene 95.0 81.7 91.2 99.8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com