Yellow to red composite reactive dye

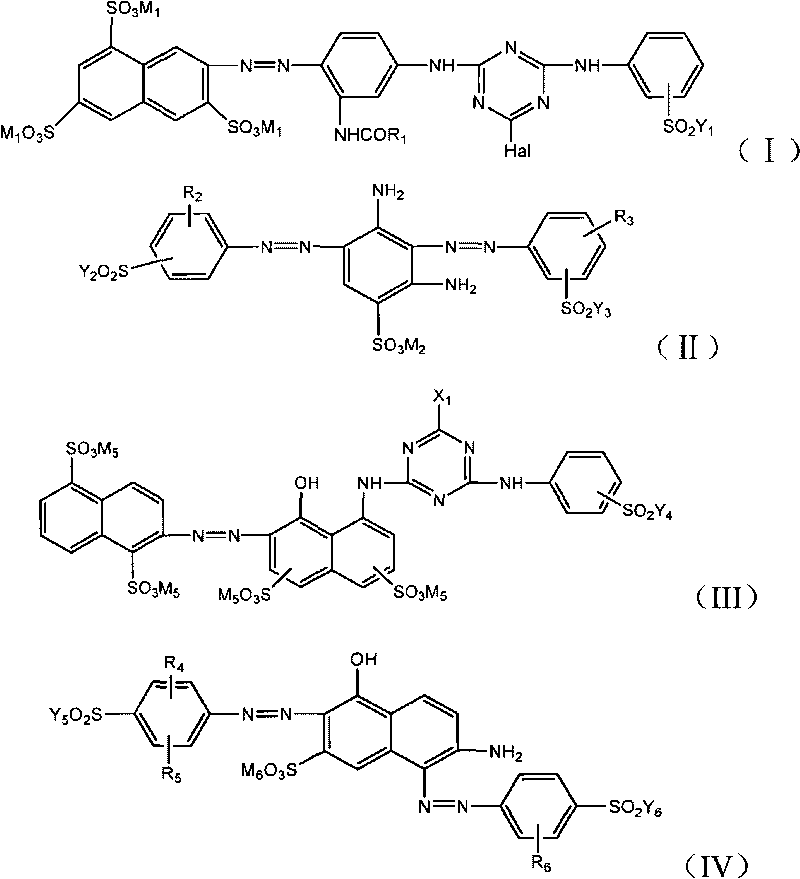

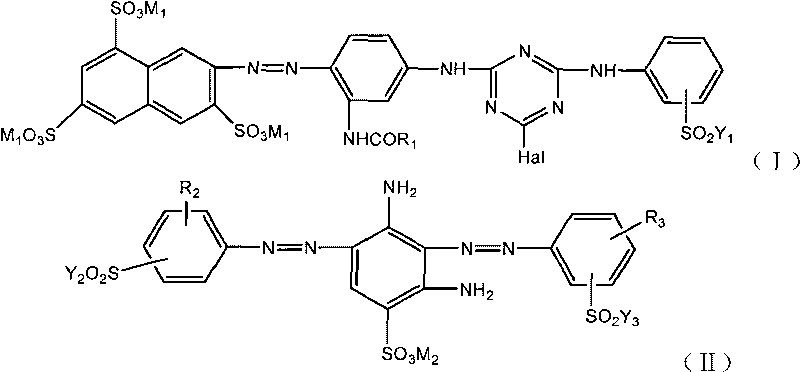

A reactive dye and red technology, applied in the field of yellow to red composite reactive dyes, can solve the problems of colored sewage, color fixation rate and fastness performance can not fully meet the demand, etc. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The synthesis of formula (I-1) structural dye A:

[0040]After beating 0.1mol of 3,6,8-trisulfonic acid-2-naphthylamine evenly, use ice to maintain the temperature at 5-8°C, add hydrochloric acid and sodium nitrite solution to carry out diazotization reaction, and then pour the diazonium Add 0.1mol of m-urea amidoaniline hydrochloride hydrochloride to carry out coupling reaction at 5-10°C and pH4-6, and then carry out coupling reaction with 0.1mol of cyanuric chloride at 0-5°C until the end of the coupling For primary condensation, keep the temperature at 0-15°C and pH 4-6. After the reaction is completed, add 0.1mol of p-(β-sulfate ethyl sulfone) aniline for secondary condensation, control the temperature at 40-60°C, pH 5-7, and the reaction ends The final dye solution is desalted and dried to obtain the dye A with the structure of the following formula (I-1).

[0041]

[0042] The remaining dyes of formula (I) in the present invention can be prepared by referring ...

Embodiment 2

[0050] Add 90 parts of dye A of formula (I-1), 10 parts of dye B of formula (II-1), 45 parts of sodium sulfate, add 350 parts of water, stir and mix, adjust the pH value of the dye solution to 5.5-6.5, and dry The dye solution is prepared from the composite reactive dye, and according to the conventional dyeing method of the reactive dye, the dyeing and printing of the yellow tone can be obtained on the cotton fabric.

Embodiment 3

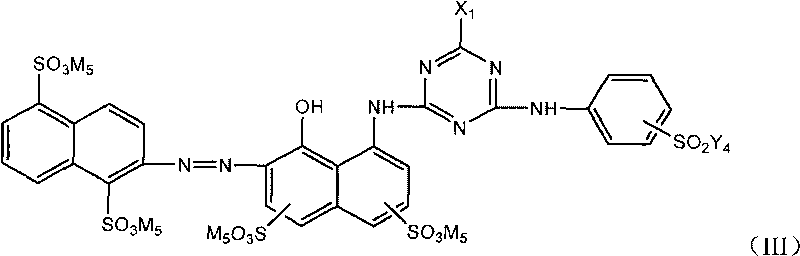

[0052] The synthesis of formula (III-1) structural dye C:

[0053] Mix 0.1 mol of cyanuric chloride and dispersant in the presence of ice to beat evenly, add 0.1 mol of p-(β-sulfate ethyl sulfone) aniline to condense once, control pH 2~3, temperature 6~12°C, after the reaction is completed, Add 1 part of H acid for secondary condensation, control pH 3~5, temperature 25~35°C, cool down to 20~30°C after the reaction, and finally couple with 1,5-disulfonic acid-2-naphthylamine diazonium salt, The dye solution after the coupling is desalted and dried to obtain the dye C with the structure of the following formula (III-1).

[0054]

[0055] The remaining dyes of formula (III) in the present invention can be prepared by referring to the above-mentioned similar method.

[0056] The synthesis of formula (IV-4) structural dye D:

[0057] Beat 0.2mol of p-(β-sulfate ethyl sulfone) aniline evenly, add hydrochloric acid and cool down to 5°C with ice, add sodium nitrite solution and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com