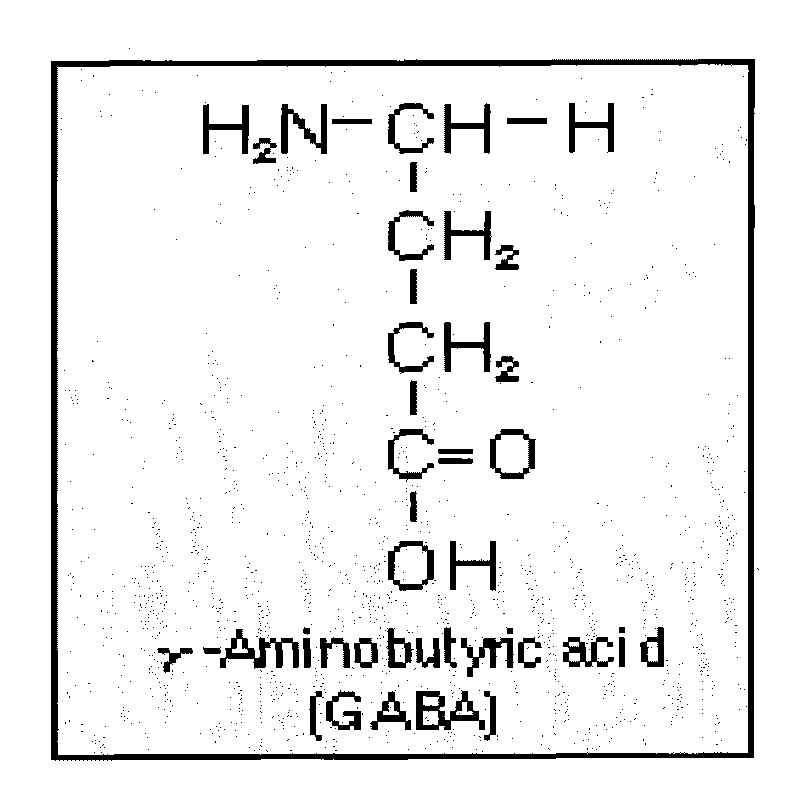

Production process of tea gamma-aminobutyric acid

An aminobutyric acid and production process technology, which is applied in the field of tea γ-aminobutyric acid production process, can solve the problems of insufficient processing depth, many tea by-products, low technological content, etc., to improve kidney function, liver function, The effect of promoting alcohol metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

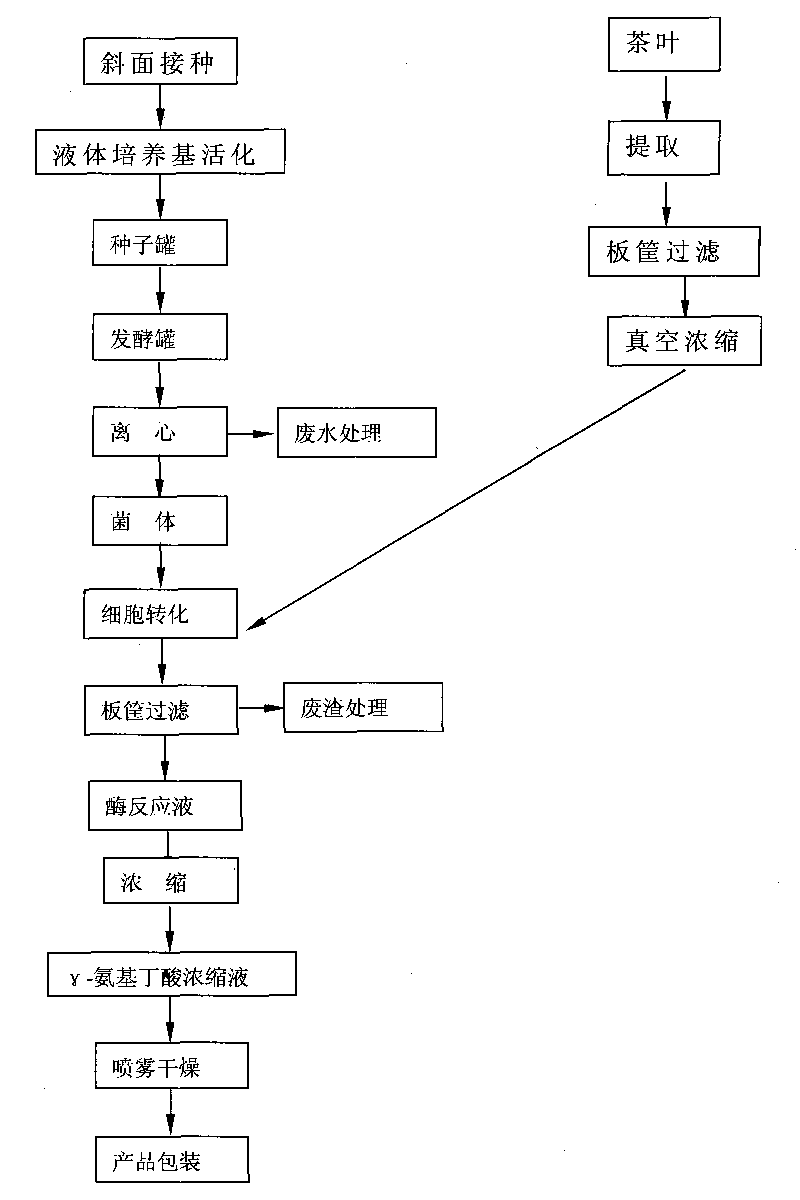

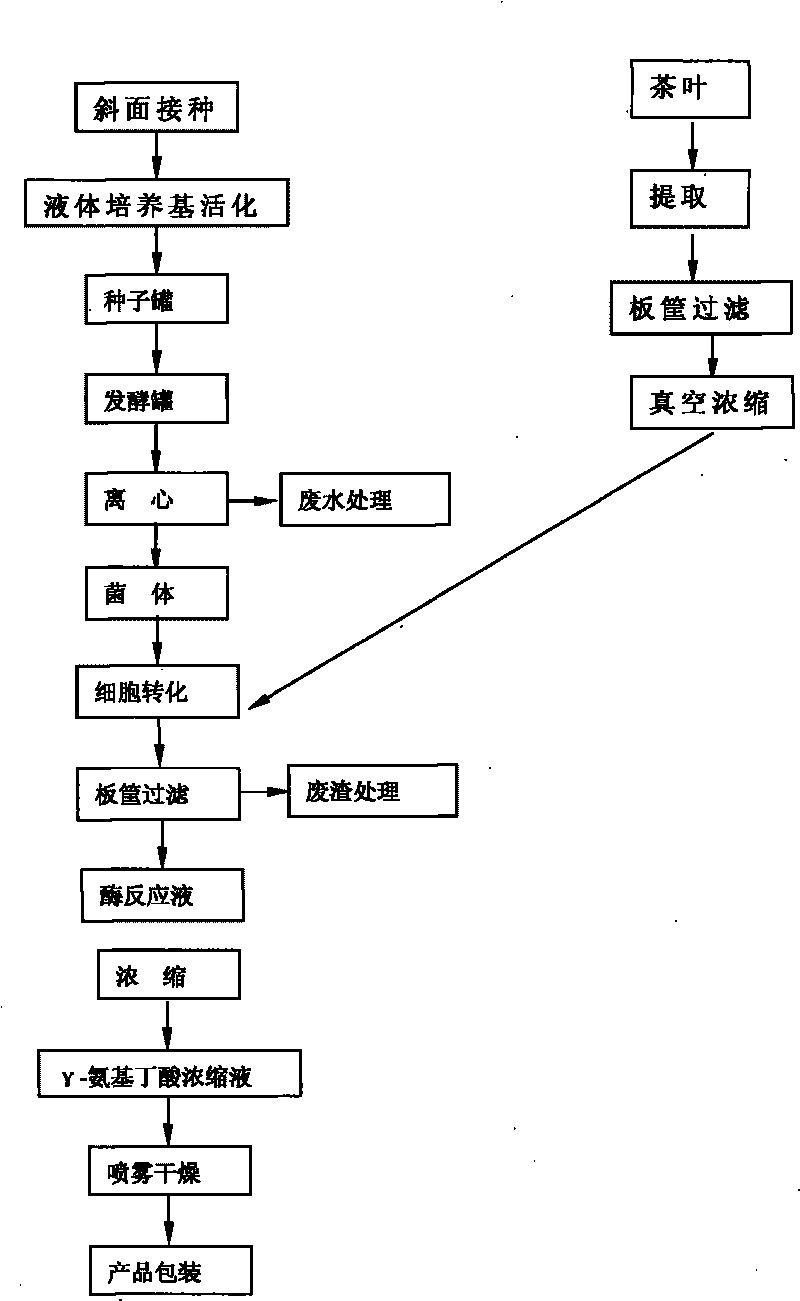

[0018] Such as figure 2 Shown, a kind of production technology of tea gamma-aminobutyric acid (GABA), is the gamma-aminobutyric acid extract that is obtained by the fermented gamma-aminobutyric acid bacterial liquid that obtains after the fermentation of lactic acid bacteria, cell conversion and tealeaves Filtration and mixing, adding enzyme reaction solution, vacuum concentration and spray drying to form tea γ-aminobutyric acid (GABA) powder. The steps of this embodiment are:

[0019] 1. Slope inoculation culture

[0020] Prepare solid slant medium according to the slant medium formula, and the strain preservation medium (solid slant medium (g / L)) formula is: yeast flavor 10, glucose 15, calcium carbonate 15, agar 15, pH 6.8.

[0021] Put the prepared medium formula into test tubes while hot (the liquid volume is 1 / 4 of the total height of the test tubes), sterilize at 0.1Mpa for 20 minutes, spread it on a slope, cool it and inoculate it, put it into a 30°C constant temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com