Composite electrostatic spinning integrated by initiator and preparation method thereof

A technology of electrospinning and composite electrostatics, which is applied in the direction of spinning solution preparation, conjugated synthetic polymer artificial filament, textiles and papermaking, etc. Issues such as technical implications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Polystyrene as Polymer Backbone by Initiator-Integrated Composite Electrospinning. Specific steps are as follows:

[0032] Weigh 10g polystyrene (PS) and 5g polydimethylsiloxane (PDMS) precursors and dissolve them in 90g tetrahydrofuran (THF), add 0.5g PDMS self-contained curing agent and 0.05g initiator A (structure: ).

[0033] Among them, PS molecular formula: Molecular formula of PDMS precursor: Molecular formula of curing agent:

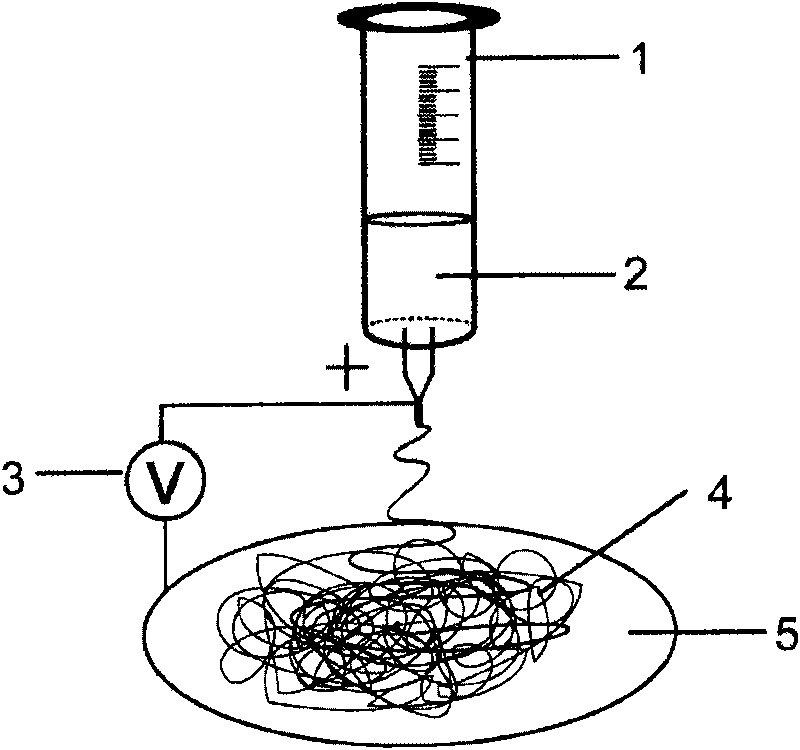

[0034] The above mixture was magnetically stirred for 5-12 hours to prepare a uniform spinning solution. Such as figure 1 As shown, the spinning solution 2 is placed in the spinneret 1 , the working distance between the spinneret and the receiving substrate 5 is 10 cm, and a voltage of 10 kV is applied by a high voltage power supply 3 . Electrospinning 4 is deposited on a receiving substrate 5 . The prepared PS-PDMS composite electrospinning was heated to 65°C for 5 hours, the PDMS precursor was cured into PDMS...

Embodiment 2

[0036] Using the same method as in Example 1, the preparation of polyacrylonitrile is the composite electrospinning of the initiator integration of the macromolecular skeleton, and the specific steps are as follows:

[0037] Weigh 20g polyacrylonitrile (PAN) and 10g polydimethylsiloxane (PDMS) precursors and dissolve them in 80g dimethylformamide (DMF), add 1g PDMS self-contained curing agent and 0.1g initiator A (the structural formula is the same as above). The above mixture was magnetically stirred for 5-12 hours to prepare a uniform spinning solution. Such as figure 1 As shown, the spinning solution 2 is placed in the spinneret 1 , the working distance between the spinneret and the receiving substrate 5 is 10 cm, and a voltage of 10 kV is applied by a high voltage power supply 3 . Electrospinning 4 is deposited on a receiving substrate 5 . The prepared PAN-PDMS composite electrospinning was heated to 65°C for 5 hours, the PDMS precursor was cured into PDMS elastomer un...

Embodiment 3

[0039] Using the same method as in Example 1, changing the amount of curing agent and the type of initiator, the preparation of polystyrene is the composite electrospinning of the integration of the initiator of the polymer skeleton, and the specific steps are as follows:

[0040] Weigh 10g polystyrene (PS) and 5g polydimethylsiloxane (PDMS) precursors and dissolve them in 90g tetrahydrofuran (THF), add 1.0g PDMS self-contained curing agent and 0.05g initiator B (structural formula: ). The above mixture was magnetically stirred for 5-12 hours to prepare a uniform spinning solution. Such as figure 1 As shown, the spinning solution 2 is placed in the spinneret 1 , the working distance between the spinneret and the receiving substrate 5 is 10 cm, and a voltage of 10 kV is applied by a high voltage power supply 3 . Electrospinning 4 is deposited on a receiving substrate 5 . The prepared PS-PDMS composite electrospinning was heated to 65°C for 5 hours, the PDMS precursor was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com