Construction method for hoisting broad width steel box girder cantilever

A construction method and technology of steel box girders, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as large deformation of steel box girders, difficulty in ensuring construction quality and construction period, and difficulty in aligning steel box girders , to achieve the effect of improving construction efficiency, shortening construction period and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

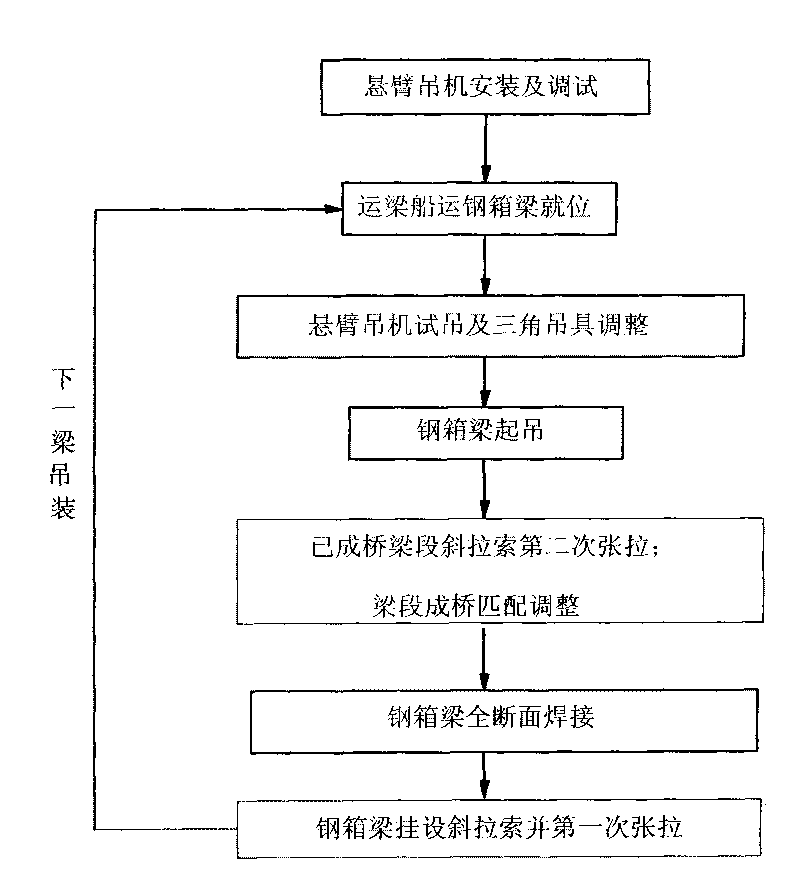

[0049] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and through specific embodiments.

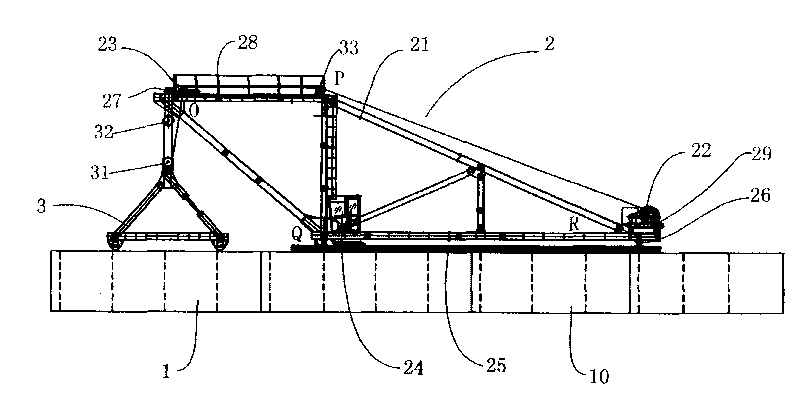

[0050] A bridge is a cable-stayed bridge with single-column leaning tower space torsion cables and hybrid girders. The span of the main navigation hole is 109+188+88m, of which 188+88m is 22 segmental steel box girders with a width of 44m and a height of 3.5m, is a wide steel box girder. Among them, the self-weight of the steel box girder of the 3-14# standard section is about 288 tons, and the maximum self-weight of the 15-20 beam section is about 331 tons. The overall hoisting construction of the steel box girder is that sections 1, 2, and 15 to 22 are hoisted and slipped into place with full brackets, and the steel box girder of the standard section 3 to 14 adopts the method of the present invention and is hoisted and adjusted by a DQP200t cantilever crane. bit.

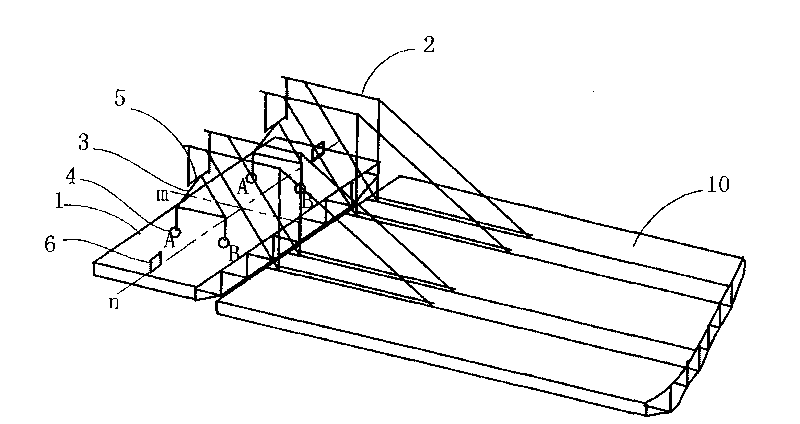

[0051] see figure 1 As shown, a kind of wide steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com