Multi-layer circulation dryer

A multi-layer circulation and dryer technology, applied in progressive dryers, dryers, drying chambers/containers, etc., can solve the problems of high heat energy consumption, large space occupation, air environment pollution, etc., and improve the utilization rate of heat energy. , The equipment occupies a small space, and the effect of improving the drying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

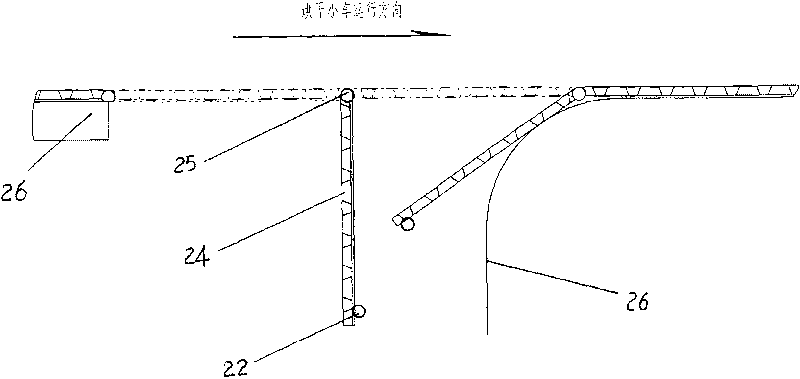

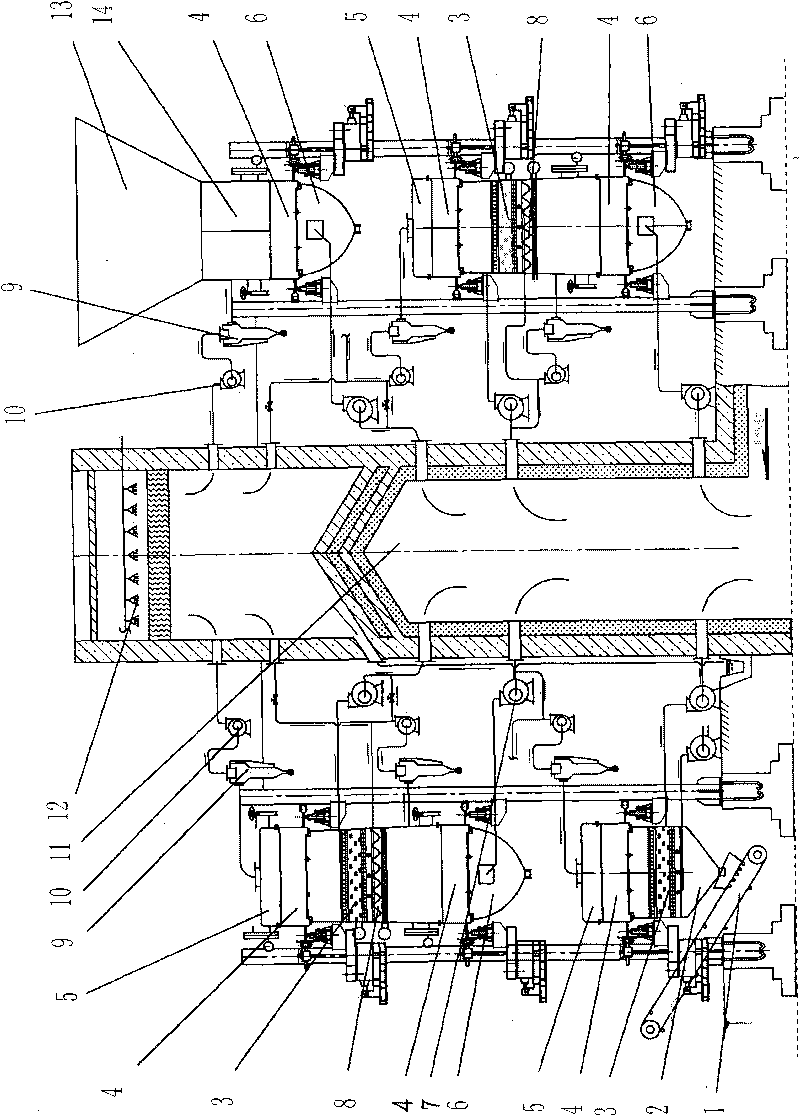

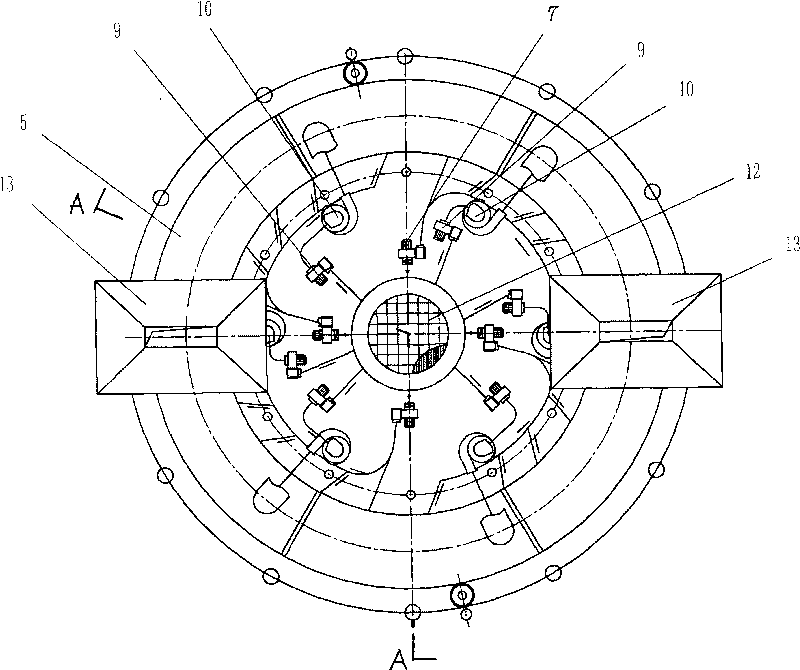

[0026] see figure 1 , 2 4. The specific structure of the present invention is as follows: the dedusting and desulfurization tower 12 and the hot flue gas chamber 11 are arranged up and down, and the dedusting and desulfurization tower 12 and the hot flue gas chamber 11 both adopt existing technical solutions. Three layers of annular drying facilities are provided on the outer periphery of the dust removal and desulfurization tower 12 and the hot flue gas chamber 11, the upper part of each layer of drying facilities is the annular drying chamber 5, and the lower part of the annular drying chamber 6 is provided. The annular drying chamber 5 is connected to the dust removal and desulfurization tower 12 through the exhaust pipe, and the dust collector 9 and the induced draft fan 10 are connected to the exhaust pipe. The annular air chamber 6 is connected to the hot smoke air chamber 11 through an air inlet duct, and a blower 7 is connected to the air inlet duct. The bottom of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com