Method for eliminating surface defect of semiconductor device and semiconductor device

A device surface, semiconductor technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting wiring integrity, epitaxy front lines, pattern defects, etc., to eliminate surface defects, reduce pollution, and improve yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

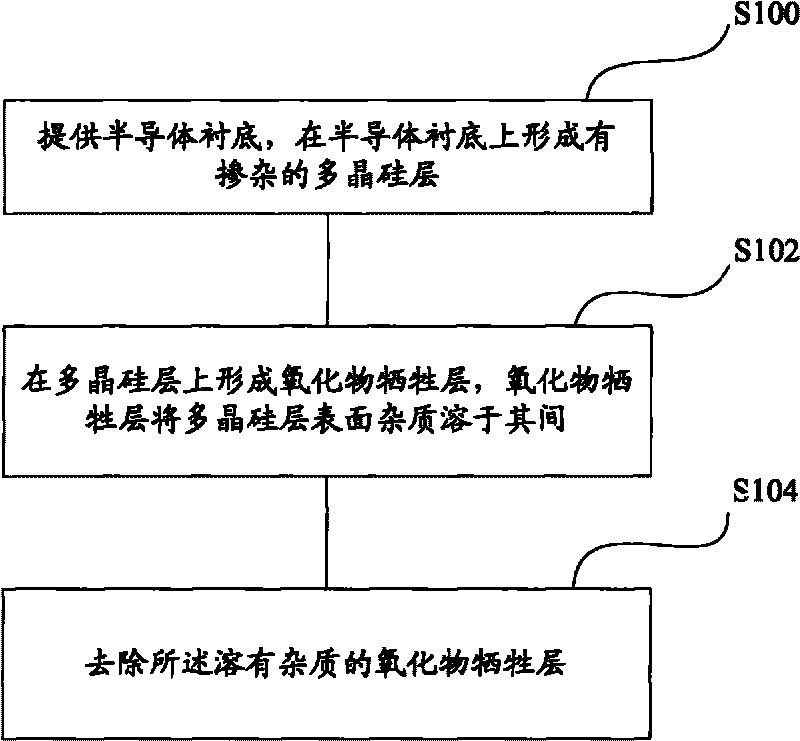

[0027] The inventors found that in the process of manufacturing semiconductor devices, when the polysilicon layer is formed, the surface of the silicon chip will be damaged by impurities (such as microparticles, fine fibers, carbon-containing organic matter, oil stains, SiH 4 Contamination of impurities in semiconductors, etc.) causes surface defects, affects the electrical properties of semiconductor devices, and leads to a decline in yield.

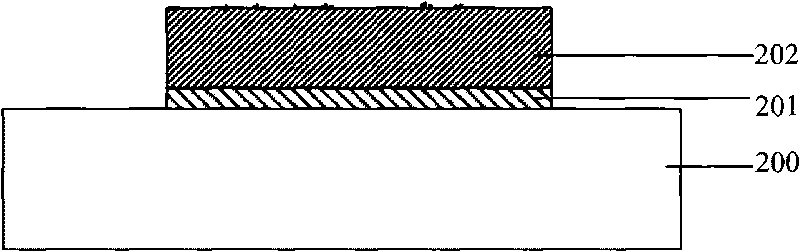

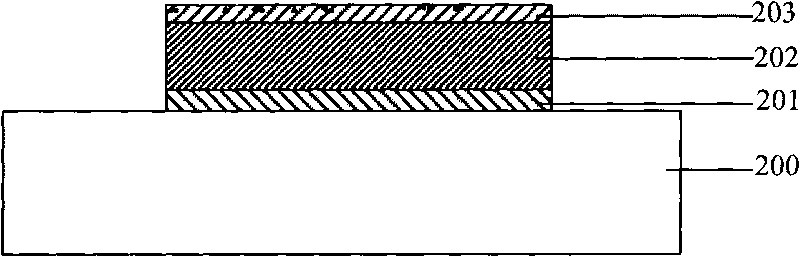

[0028] Therefore, in the manufacture of semiconductor devices, in order to prevent the above-mentioned defects, especially surface impurities, from affecting the product yield. The invention provides a method for eliminating surface defects of a semiconductor device, comprising: providing a semiconductor substrate, on which a doped polysilicon layer is formed, and impurities are attached to the surface of the polysilicon layer; forming an oxide sacrificial layer on which the impurity is dissolved; and removing the oxide sacrificial laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com