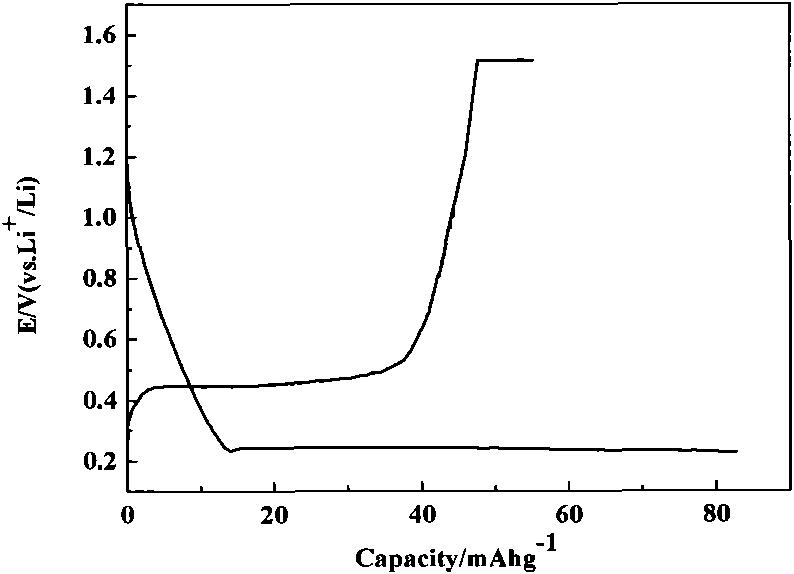

Low-temperature hydrothermally synthesized organic phosphonic acid lithium battery anode material LixMmR(PO3)n

A technology of organic phosphonic acid and hydrothermal synthesis, which is applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of lack of controllable composition and structure design, and achieve the effects of optimized charge and discharge performance, low cost, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

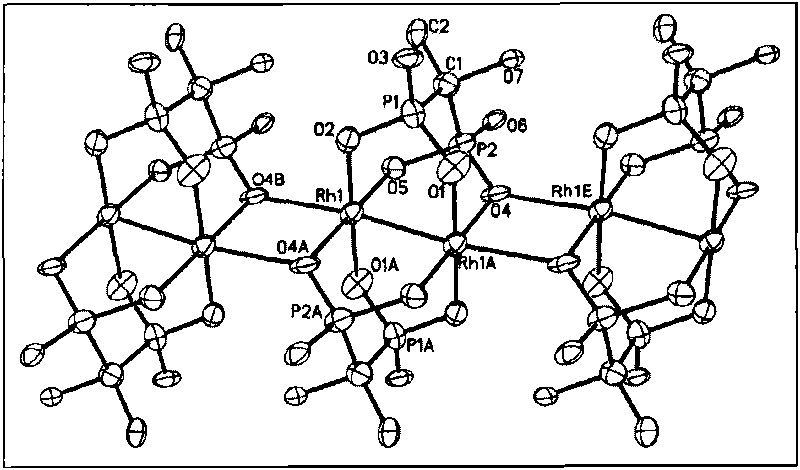

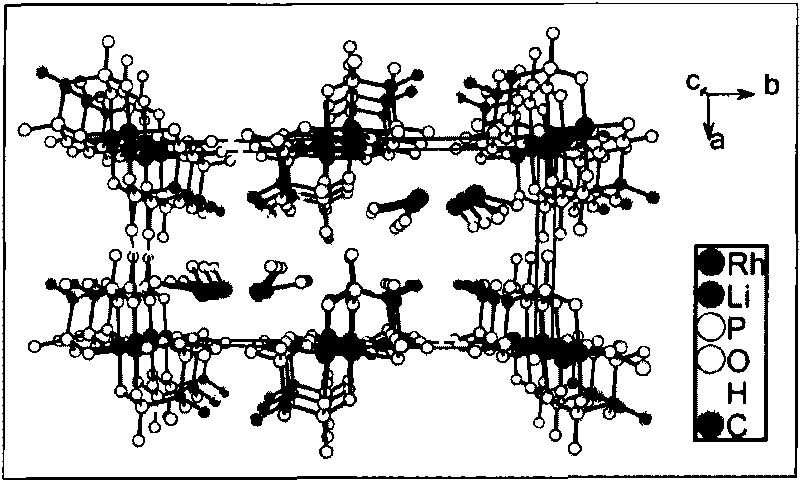

[0022] Example 1, Li 2 [Rh 2 (CH 3 C(OH)(PO 3 h 0.5 ) 2 ) 2 ]·4H 2 Synthesis of O

[0023] RhCl 3 ·3H 2 O 2.5723g (9.77mmol), 1-hydroxyethyl diphosphonic acid CH 3 C(OH)(PO 3 h 2 ) 2 ·H 2 O6.5654g (29.30mmol) mixed with 40mL of water, 1M LiOH to adjust the pH of the solution to 3.30, stirred at room temperature for 2 hours, put the solution into a polytetrafluoroethylene-lined reactor and sealed, heated to 140°C by program, and reacted at constant temperature for 3 Day, program cooling to room temperature, filtration, deionized water, ethanol, acetone washing, vacuum drying to obtain pure green needle-like crystals 3.2673g, yield 95.9% (based on Rh). Chemical formula C 4 h 18 o 18 P 4 Li 2 Rh 2 , elemental analysis (%) calculated value: C, 6.88; H, 2.60; measured value: C: 5.70; H, 2.56.

[0024] Infrared spectrum IR (KBr, cm -1 ): 3508(s), 3419(br,s), 3216(br,s), 2947(m), 1655(s), 1457(m), 1370(s), 1155(vs), 1135(vs) , 1072(vs), 1016(vs), 971(vs), 927(v...

Embodiment 2

[0028] Example 2, Li 3 [Ru 2 (CH 3 C(OH)(PO 3 ) 2 ) 2 ]·2H 2 Synthesis of O

[0029] RuCl 3 3.5H 2 O 0.1015g (0.38mmol), 1-hydroxyethyl diphosphonic acid CH 3 C(OH)(PO 3 h 2 ) 2 ·H 2 O0.3367g (1.50mmol) was mixed in 4mL water, adjusted to pH = 4.70 with 1M LiOH, the mixture was put into a stainless steel reactor lined with polytetrafluoroethylene, the temperature was raised to 160°C, and the temperature was reacted for 4 days, and the temperature was lowered to room temperature, filtered, washed with deionized water, ethanol, and acetone, and dried in vacuum to obtain 0.120 g of reddish-brown fibrous crystals with a yield of 95% (based on Ru). Chemical formula C 4 h 12 o 16 P 4 Li 3 Ru 2 Elemental analysis (%) Found value: C, 7.10; H, 1.95; Theoretical value: C, 7.25; H, 1.82%.

[0030] Infrared spectrum IR (KBr, cm -1 ): 3418(s), 1647(s), 1457(w), 1370(w), 1144(s), 1067(m), 975(s), 915(m), 819(w), 587(s ), 492(m).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com