Formation method of lithium ion secondary battery using lithium titanate as cathode

A technology of secondary battery and formation method, which is applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, non-aqueous electrolyte storage battery, etc., which can solve problems such as gas swelling, affecting battery capacity and cycle performance, and achieves guaranteed The effect of capacity and circulation, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

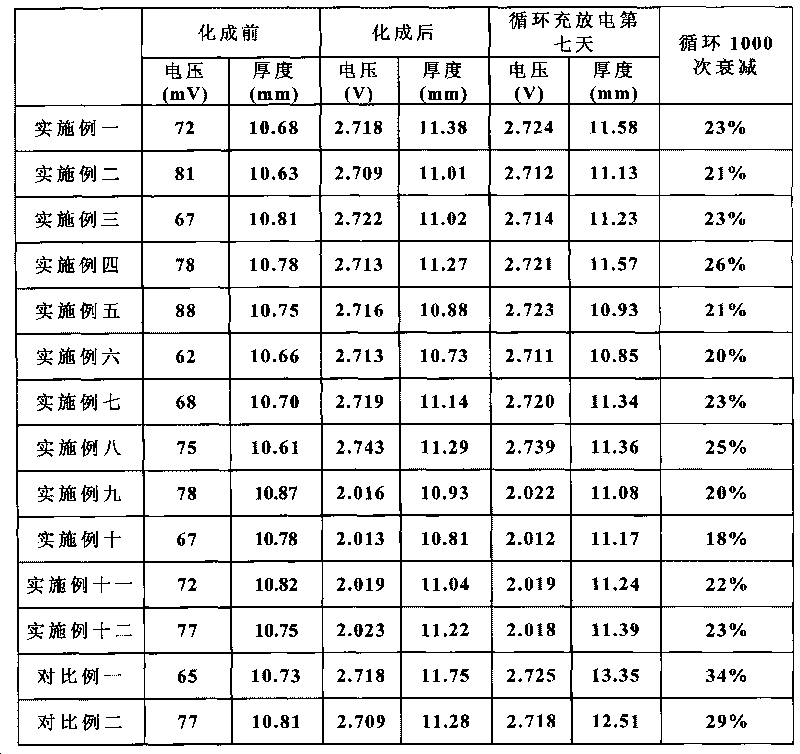

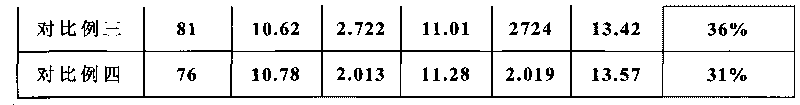

Embodiment 1

[0016] Lithium manganate is used as the positive electrode active material, lithium titanate is used as the negative electrode active material, and the electrolyte LiPF 6 Dissolved in a mixed solution of ethylene carbonate (EC) / dimethyl carbonate (DMC) with a volume ratio of 1:1 to form an electrolyte, the concentration of the electrolyte is 1 mol / liter, and a battery is made, and the prepared battery Under the condition of a formation temperature of 15°C, it was charged at a constant current of 0.3C to 2.7V, and then charged at a constant voltage to the cut-off current to form a solid electrolyte interface film on the surface of the negative electrode material, then vacuum sealed, and then a cycle test was performed.

Embodiment 2

[0018] Lithium manganate is used as the positive electrode active material, lithium titanate is used as the negative electrode active material, and the electrolyte LiPF 6 Dissolved in a mixed solution of ethylene carbonate (EC) / dimethyl carbonate (DMC) with a volume ratio of 1:1 to form an electrolyte, the concentration of the electrolyte is 1 mol / liter, and a battery is made, and the prepared battery Under the condition of a formation temperature of 25°C, it was charged at a constant current of 0.3C to 2.7V, and then charged at a constant voltage to the cut-off current to form a solid electrolyte interface film on the surface of the negative electrode material, then vacuum sealed, and then a cycle test was performed.

Embodiment 3

[0020] Lithium manganate is used as the positive electrode active material, lithium titanate is used as the negative electrode active material, and the electrolyte LiPF 6 Dissolved in a mixed solution of ethylene carbonate (EC) / dimethyl carbonate (DMC) with a volume ratio of 1:1 to form an electrolyte, the concentration of the electrolyte is 1 mol / liter, and a battery is made, and the prepared battery Under the condition of formation temperature of 50°C, charge at 0.3C constant current to 2.7V, and then charge at constant voltage to cut-off current to form a solid electrolyte interface film on the surface of the negative electrode material, then vacuum seal it, and then conduct a cycle test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com