Ultrasmall DC electric motor capable of preventing fracture of root of wire

A DC motor and ultra-miniature technology, applied in the field of micro motors, can solve the problems of difficult processing, affecting the life of the motor, and large harmful gases, and achieve the effects of facilitating bearing processing, avoiding brush deformation, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

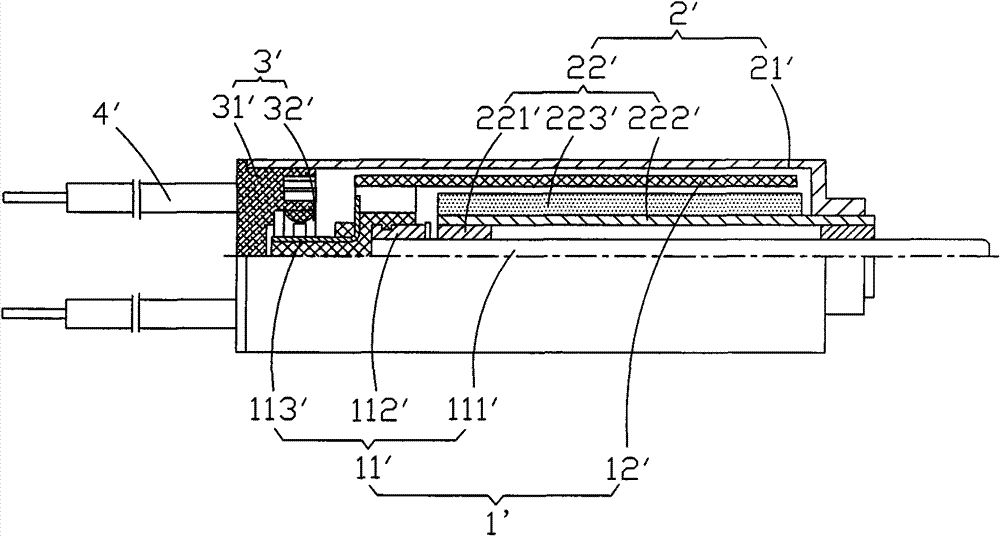

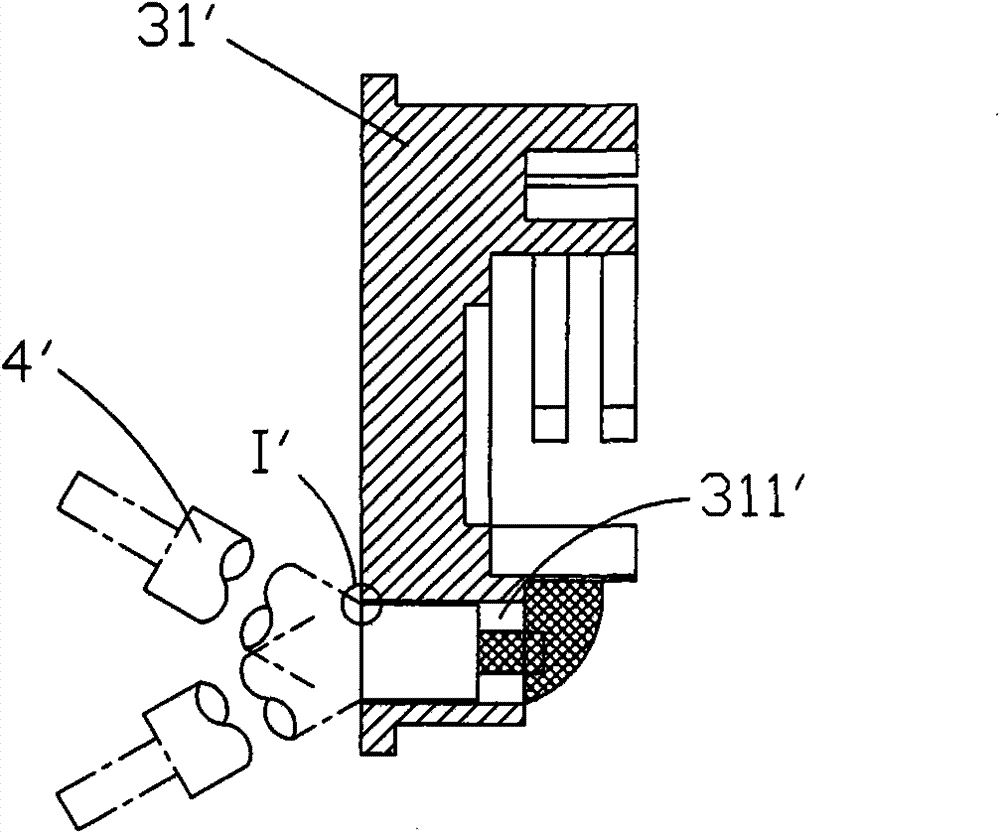

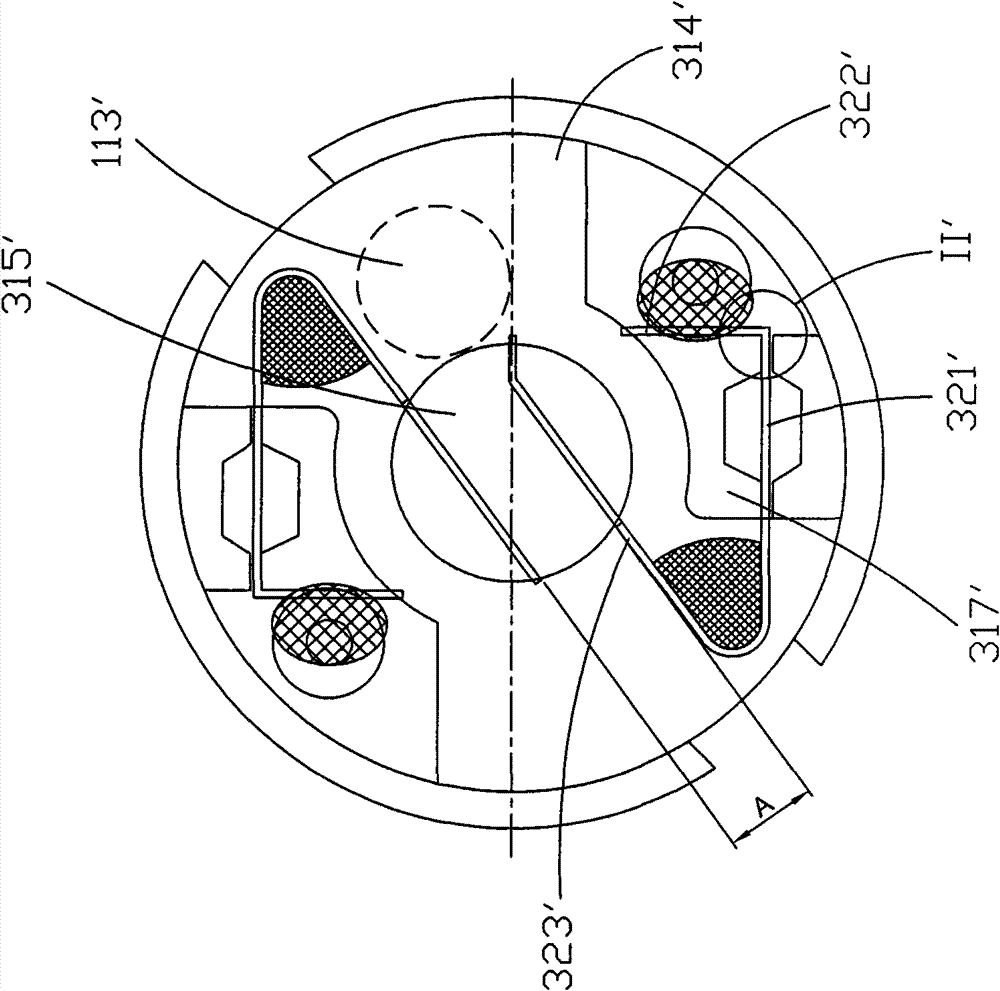

[0043] see Figure 6 , is a preferred embodiment of the present invention can prevent the breakage of the ultra-miniature DC motor, the motor includes a rotor 1, a stator 2 and a brush group 3. The rotor 1 includes a rotor frame 11 and a winding 12 ; the rotor frame 11 includes a rotating shaft 111 , a fixing ring 112 sleeved on one end of the rotating shaft 111 , and a commutator 113 located on one end of the rotating shaft 111 . The stator 2 includes a casing 21 and a magnetic steel assembly 22 located in the casing 21; the magnetic steel assembly 22 includes a bearing 221 sleeved on the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com