Method for extracting high-purity schisandra total lignan

A technology of total lignans and extraction methods, which can be used in pharmaceutical formulations, medical preparations containing active ingredients, anti-toxins, etc., and can solve problems such as large energy consumption, short extraction time, and organic solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

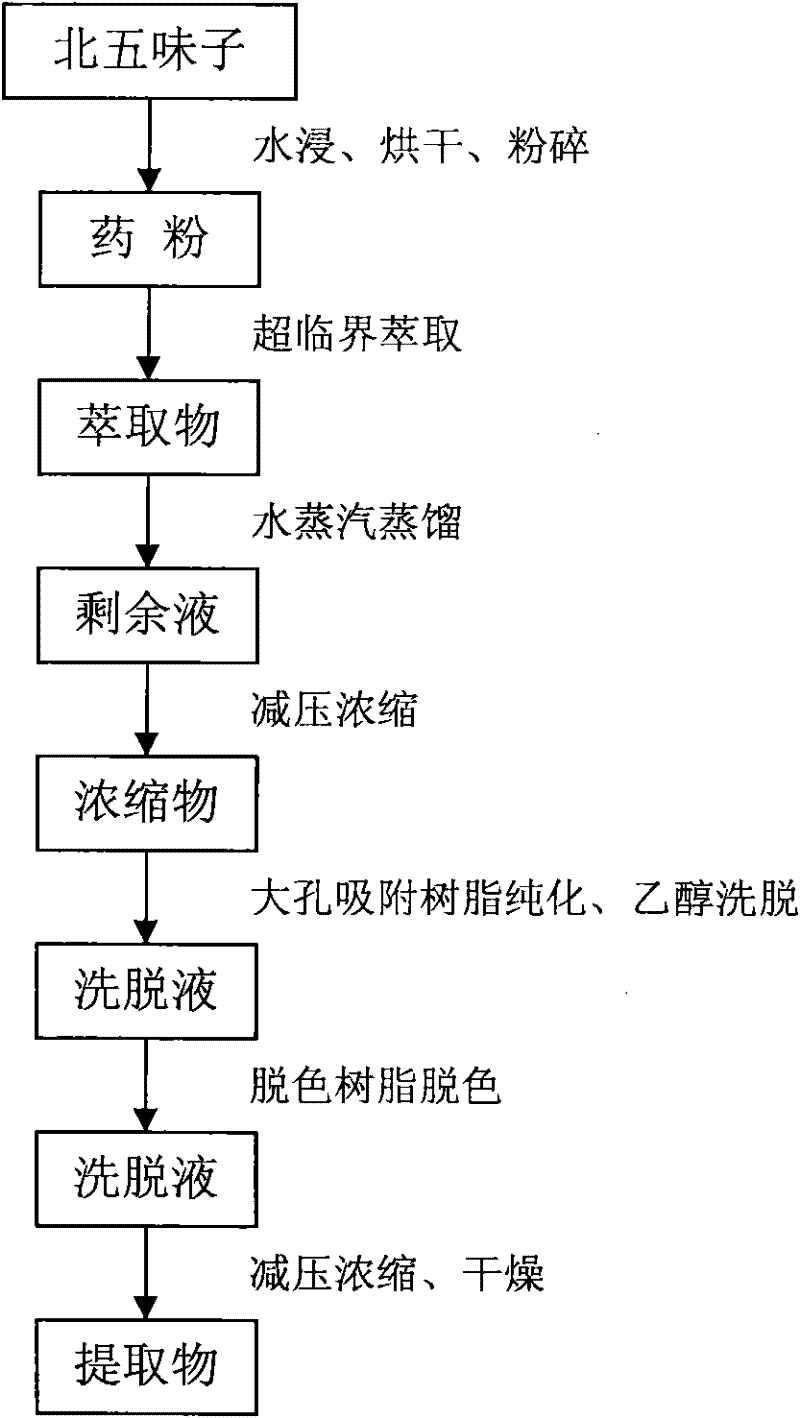

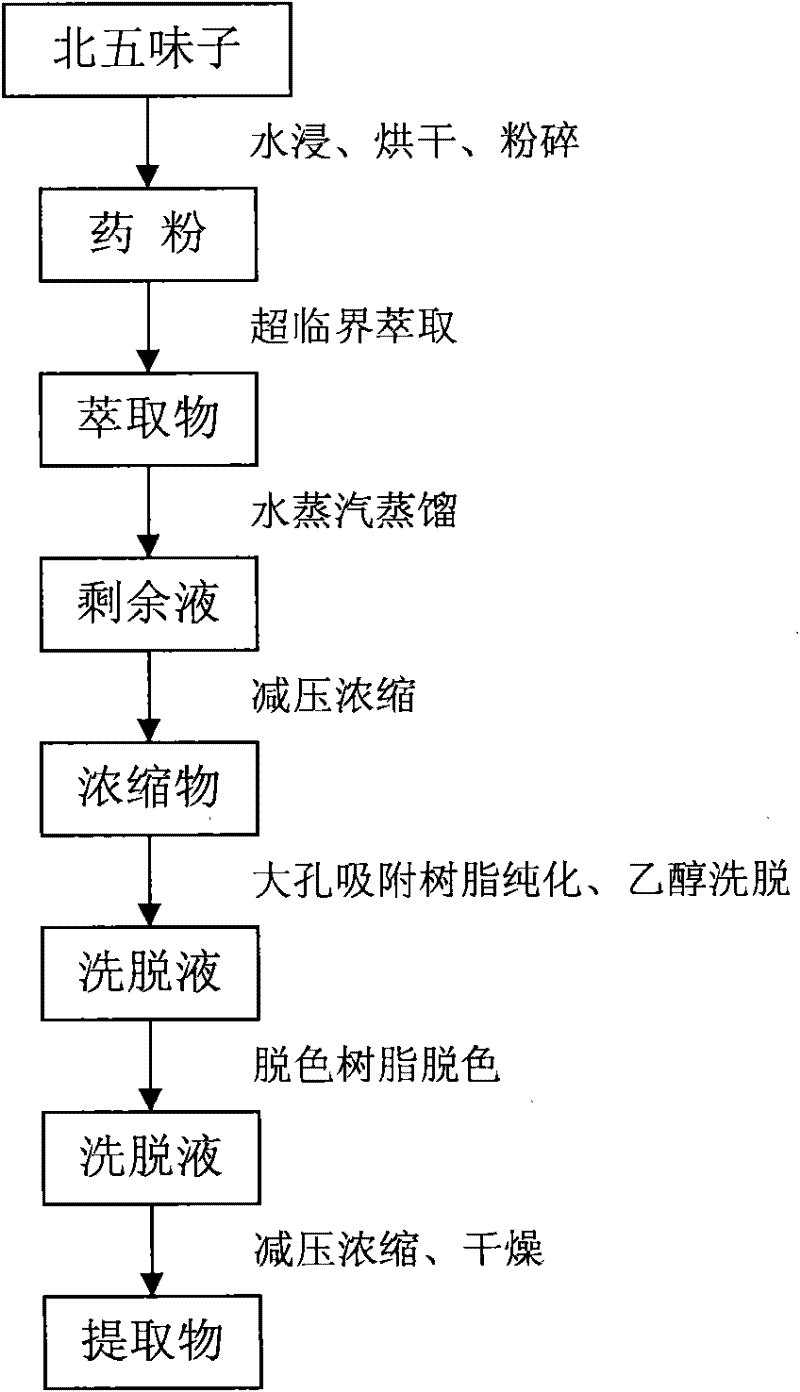

Image

Examples

Embodiment 1

[0018] Statically soak the fruit of Schisandra chinensis in water for 22 hours, and the solid-liquid ratio of fruit and water is 1:8 (w / v, g / mL); filter the soaked fruit of Schisandra chinensis, dry and pulverize the filter residue, and set aside; (2) The pulverized filter residue was treated with supercritical CO 2 extraction, the supercritical CO 2 The extraction method is carried out under the following conditions: the extraction pressure is 30 MPa, the extraction temperature is 40 ° C, CO 2 The flow rate was 12Kg / h, and the dynamic extraction was performed for 1.5 hours; the obtained extract was distilled with steam at 110°C for 6 hours, concentrated under reduced pressure to obtain a concentrate, which was set aside; (3) the concentrate

[0019] Adsorbed by macroporous adsorption resin, 30% ethanol is used to elute part of the fatty oil, and then 85% ethanol is used to elute, the eluate is decolorized by decolorizing resin, the eluate is concentrated and dried, and it is...

Embodiment 2

[0021] Statically soak the fruit of Schisandra chinensis in water for 24 hours, and the solid-liquid ratio of fruit and water is 1:6 (w / v, g / mL); filter the soaked fruit of Schisandra chinensis, dry and pulverize the filter residue, and set aside; (2) The pulverized filter residue was treated with supercritical CO 2 extraction, the supercritical CO 2 The extraction method is carried out under the following conditions: the extraction pressure is 35MPa, the extraction temperature is 50°C, and the CO 2 The flow rate is 12Kg / h, dynamic extraction for 2 hours; the obtained extract is distilled with steam at 120°C for 1 hour, concentrated under reduced pressure to obtain a concentrate, which is set aside; (3) the concentrate

[0022] Adsorbed by macroporous adsorption resin, 20% ethanol is used to elute part of the fatty oil first, and then 95% ethanol is used to elute, the eluate is decolorized by decolorizing resin, the eluate is concentrated and dried, and it is obtained; after ...

Embodiment 3

[0024] Soak Schisandra fruit statically in water for 18 hours, the solid-liquid ratio of fruit and water is 1:10 (w / v, g / mL); filter the soaked Schisandra fruit, dry and pulverize the filter residue, and set aside; (2) The pulverized filter residue was treated with supercritical CO 2 extraction, the supercritical CO 2 The extraction method is carried out under the following conditions: the extraction pressure is 25 MPa, the extraction temperature is 30 ° C, CO 2 The flow rate is 12Kg / h, dynamic extraction for 1 hour; the obtained extract is distilled with steam at 100°C for 8 hours, concentrated under reduced pressure to obtain a concentrate, which is set aside; (3) the concentrate

[0025] After being adsorbed by macroporous adsorption resin, first use 15% ethanol to elute to remove part of the fatty oil, then use 85% ethanol to elute, the eluate is decolorized by decolorizing resin, the eluate is concentrated and dried, and it is obtained; after testing, this The inventive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com