Pneumatic auxiliary threading device of numerical control electrospark wire-electrode cutting machine tool

A cutting machine and pneumatically assisted technology, used in attachments, electric processing equipment, metal processing equipment, etc., can solve the problems of molybdenum wire easily broken, easily detached from the guide wheel, easy to cut fingers by operators, and reduce labor intensity. , The effect of fast threading and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

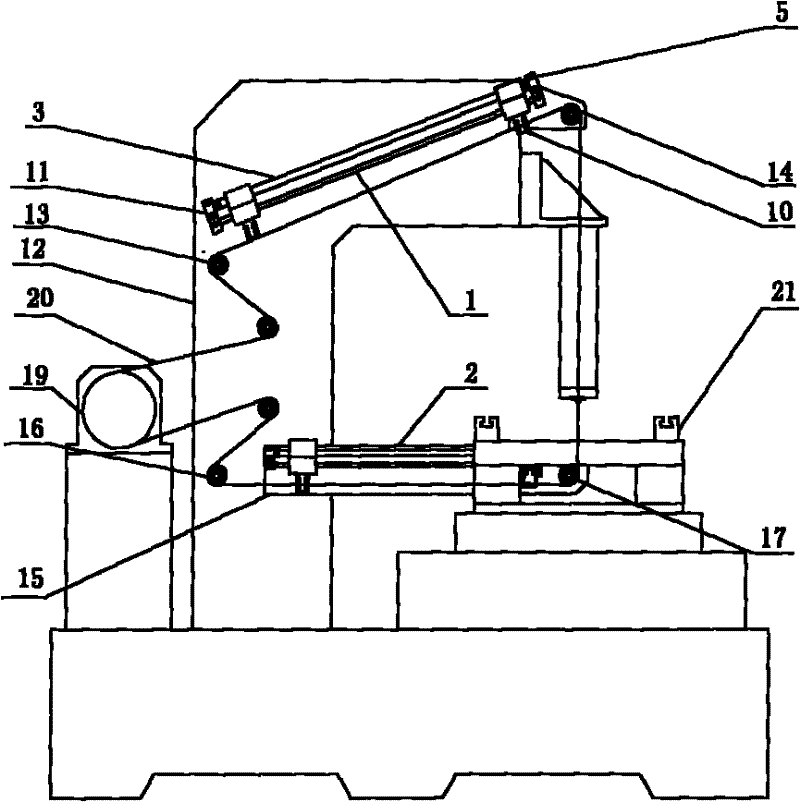

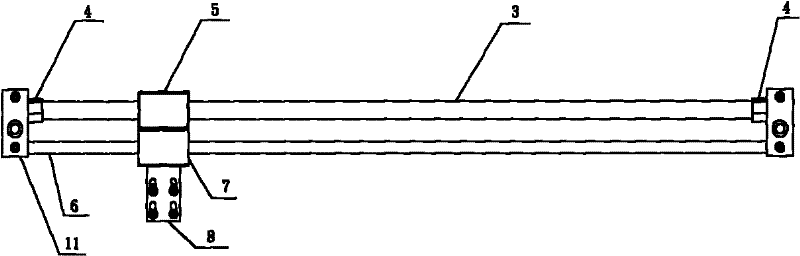

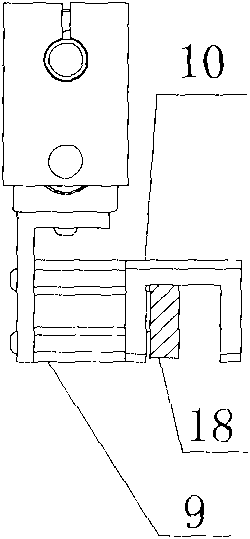

Embodiment 1

[0011] Embodiment 1: with reference to attached Figure 1~3 . A pneumatic auxiliary wire feeding device for a CNC wire cutting machine, which includes an upper wire feeder 1 and a lower wire feeder 2, the upper wire feeder 1 and the lower wire feeder 2 are provided with a magnetic rodless cylinder 3 and Two ends are provided with air inlet 4, magnetic rodless cylinder 3 is provided with magnetic rodless cylinder slide block 5, is provided with guide rail 6 below magnetic rodless cylinder 3, is provided with slide block 7 on guide rail 6 and is connected with magnetic rodless cylinder The slide block 5 is fixedly connected, and the lower end of the slide block 7 fixes the miniature cylinder 9 through the miniature cylinder holder 8, and the miniature cylinder 9 is connected with the pneumatic chuck seat 10.

[0012] The upper wire feeder 1 is fixed above the column 12 by the upper wire feeder fixing base 11 and is parallel to the upper row of wire wheels 13 and the upper guide...

Embodiment 2

[0015] Embodiment 2: A wire feeding method for a pneumatically assisted wire feeding device of a CNC wire cutting machine tool, in which the molybdenum wire 20 wound on the wire storage barrel 19 is wound around the upper wire wheel 13 and the molybdenum is clamped by the pneumatic chuck seat 10 The wire 20, the magnetic rodless cylinder slider 5 and the pneumatic chuck seat 10 slide along the guide rail 6 from the upper wire wheel 13 end to the upper guide wheel 14 end. After reaching the position, the pneumatic chuck seat 10 releases the molybdenum wire 20, and the molybdenum wire 20 Go around on the upper guide wheel 14, pass through the workbench 21 and go around on the lower guide wheel 17, then send it to the lower row of wire wheels 16 by the lower wire feeder 2 and then wind it in the wire storage barrel 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com