Synthesis and preparation process of eptifibatide

A preparation process and fibatide technology are applied in the field of eptifibatide synthesis and preparation technology, which can solve the problems of waste of hexapeptide raw materials, pressure of large-scale production costs, low yield and the like, and achieve higher yield and lower cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

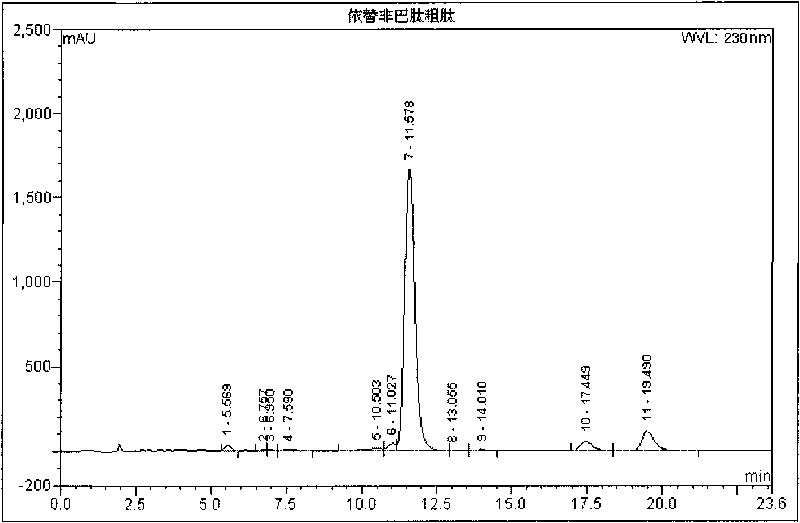

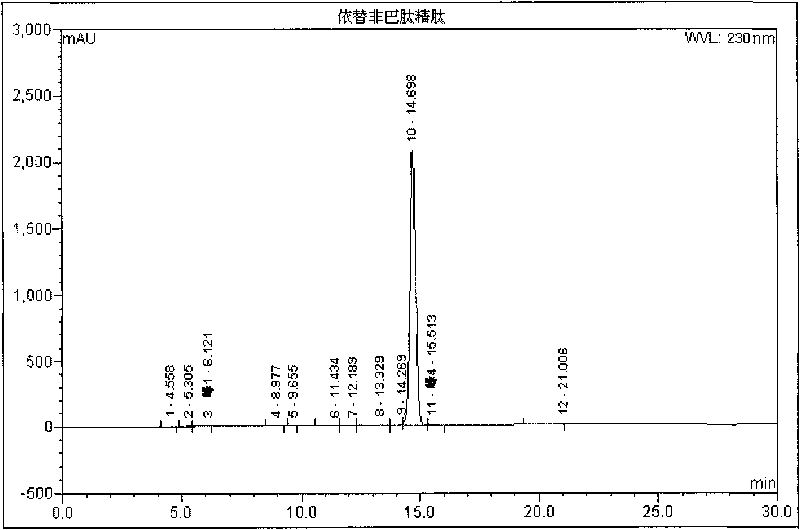

Image

Examples

Embodiment 1

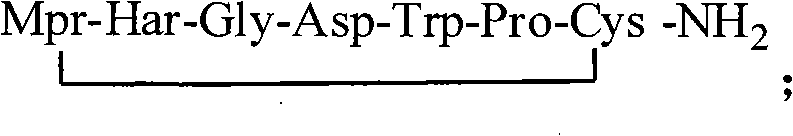

[0079] 1. Mpr(X)-Har(R) with side chain protection 4 )-Gly-Asp(R 2 )-Trp(R 3 )-Pro-Cys(Y)-NH 2 Synthesis of Linear Peptides

[0080] Route 1:

[0081] 1. Boc-Pro-Cys(acm)-NH 2 Synthesis

[0082] In a 50 ml round bottom flask was added Boc-Pro-OH (1.076g), NH 2 -Cys(acm)-NH 2 (0.960g), HOSU (N-hydroxysuccinimide) (0.575g), dissolved with 40ml of anhydrous DMF, after adding DCC (1.030g) under ice-water bath, stirred at room temperature for 2 hours, and detected that the reaction was complete. The precipitate produced by the reaction was removed by suction filtration, concentrated under reduced pressure to remove DMF, and then dissolved with a large amount of ethyl acetate, followed by 10% NaHCO 3 , 15% dilute hydrochloric acid, and saturated brine, dried over anhydrous sodium sulfate, and spin-dried ethyl acetate to obtain 1.760 g of solid. HPLC purity: greater than 92%, yield 90.5% MS=389 (M+1).

[0083] 2. Boc-Trp-Pro-Cys(acm)-NH 2 Synthesis

[0084] Weigh Boc-Pro-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com