Whey protein edible single/double-layered compound film and preparation method thereof

A whey protein, double-layer composite technology is applied in the field of food packaging materials to achieve the effects of increasing bioavailability, good film-forming properties and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

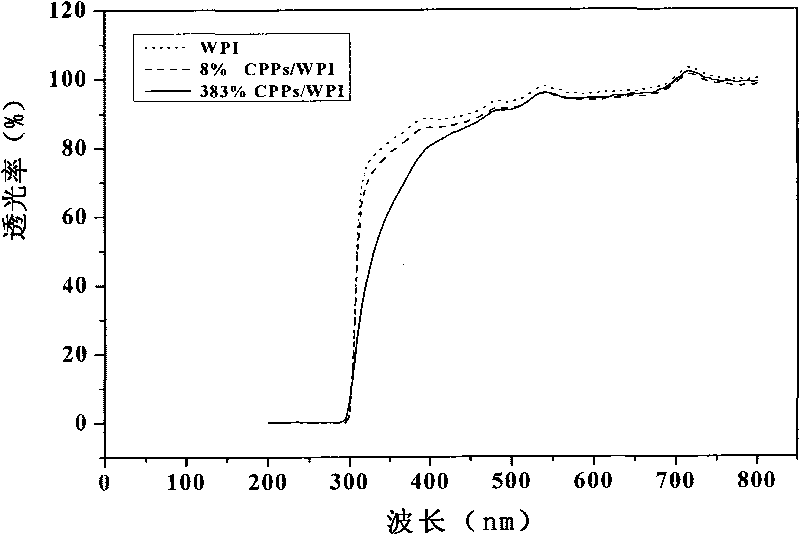

[0021] Measurements of film thickness, tensile properties, water vapor transmission coefficient, water content and solubility, as well as light transmittance and transparency in the following examples are as follows:

[0022] (1) Measurement method of film thickness: measure the thickness with a digital micrometer.

[0023] (2) Determination method of tensile properties

[0024] With reference to ASTM (1995) method, the tensile properties were measured using TMS-Pro texture analyzer, wherein the tensile speed was 1 mm / s. Tensile strength (TS, MPa) is calculated according to formula (1):

[0025] TS = F t L × W - - - ( 1 )

[0026] In the formula, F t ——Maximum pulling force (N)

[0027] L—thickness of the film sample (mm)

[0028] W——width of film sample (mm)

[0029] E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com