Exchange transmission gear capable of realizing remotely switching types of gas heated in coke oven

A transmission device and coke oven technology, which is applied to the heating of coke ovens, coke ovens, and combustible gas heating coke ovens, etc., can solve the problems of complicated, heavy workload, and trivial operation of workers, and achieve good safety and reduce labor intensity. , the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

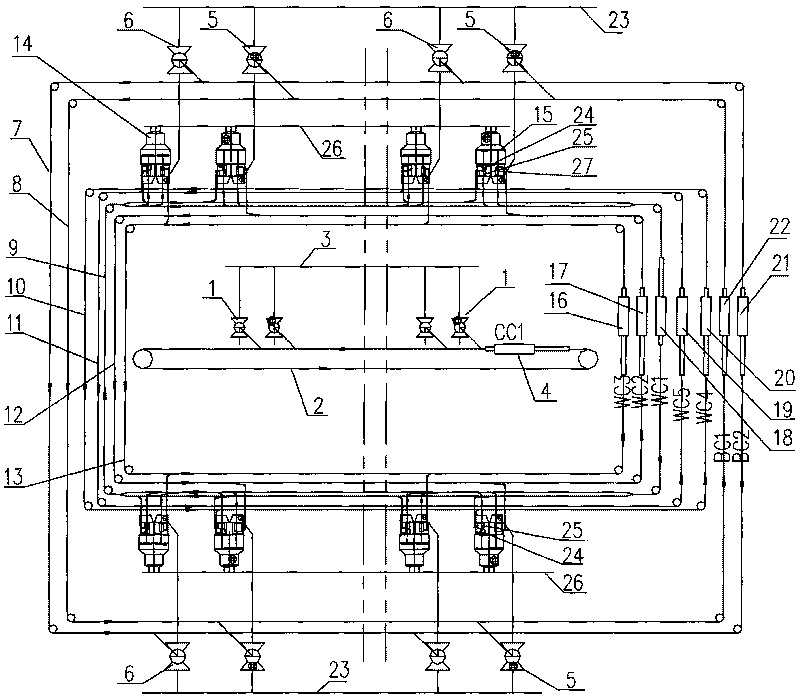

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0022] An exchange transmission device that can realize remote switching of the type of coke oven heating gas. In the following, coke oven gas represents rich gas and mixed gas represents lean gas. In the heating exchange system, red and green represent two different states at the same time. Set of gas supply units (rising gas and air and descending exhaust gas).

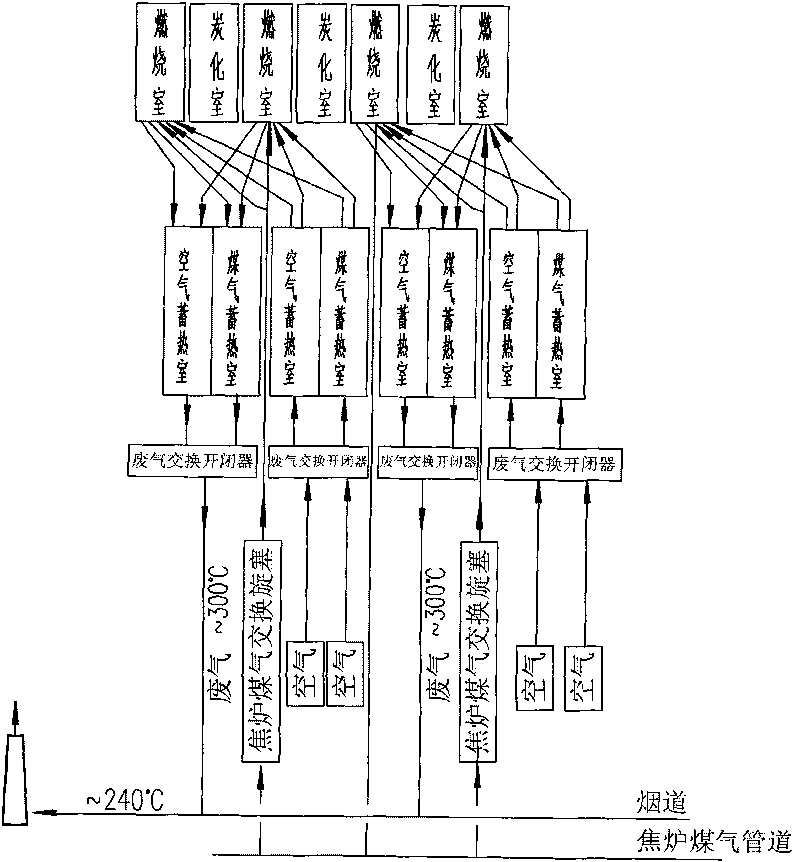

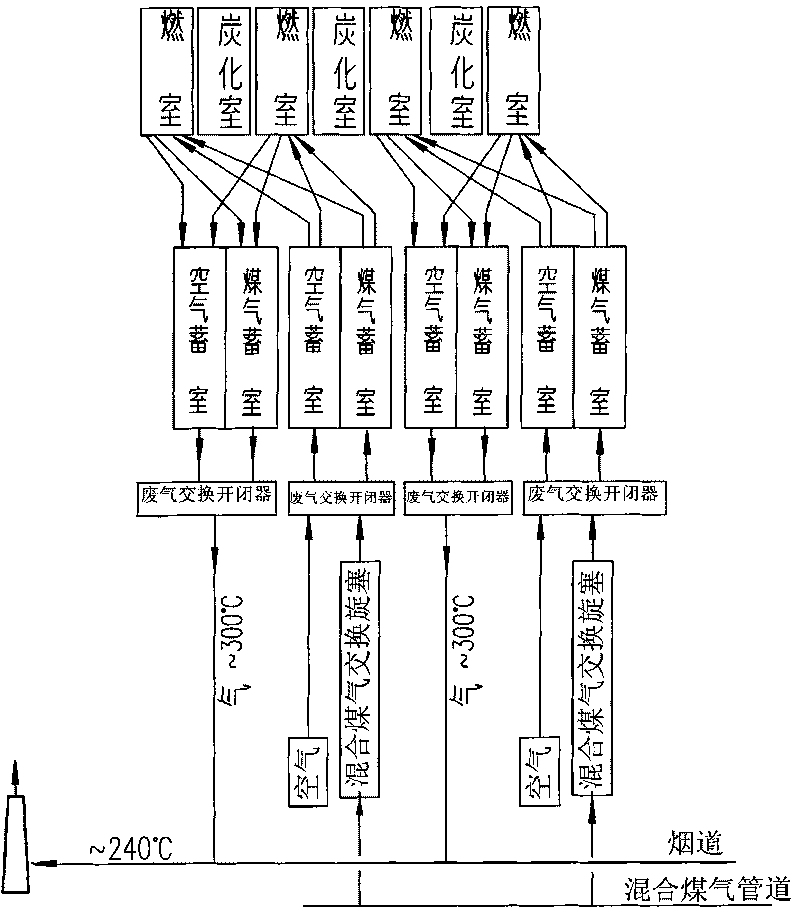

[0023] See figure 1 , the coke oven gas exchange cock is set on the coke oven gas pipeline, directly connected with the combustion chamber, the coke oven gas is combined with the air entering through the exhaust gas exchange switch and the air regenerator for combustion, and the exhaust gas after combustion is stored through the air After the sensible heat is recovered in the chamber and the gas regenerator, it is discharged into the atmosphere through the waste gas exchange switch and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com