Draft process and equipment thereof for polyethylene fibres with superhigh molecular weight

A technology of polyethylene fiber and ultra-high molecular weight, which is applied in the field of thermal drawing process and equipment, can solve the problems such as the structure of the drawing equipment that has not been proposed, and achieve the effects of reducing fuzz, increasing the speed of thread feeding, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

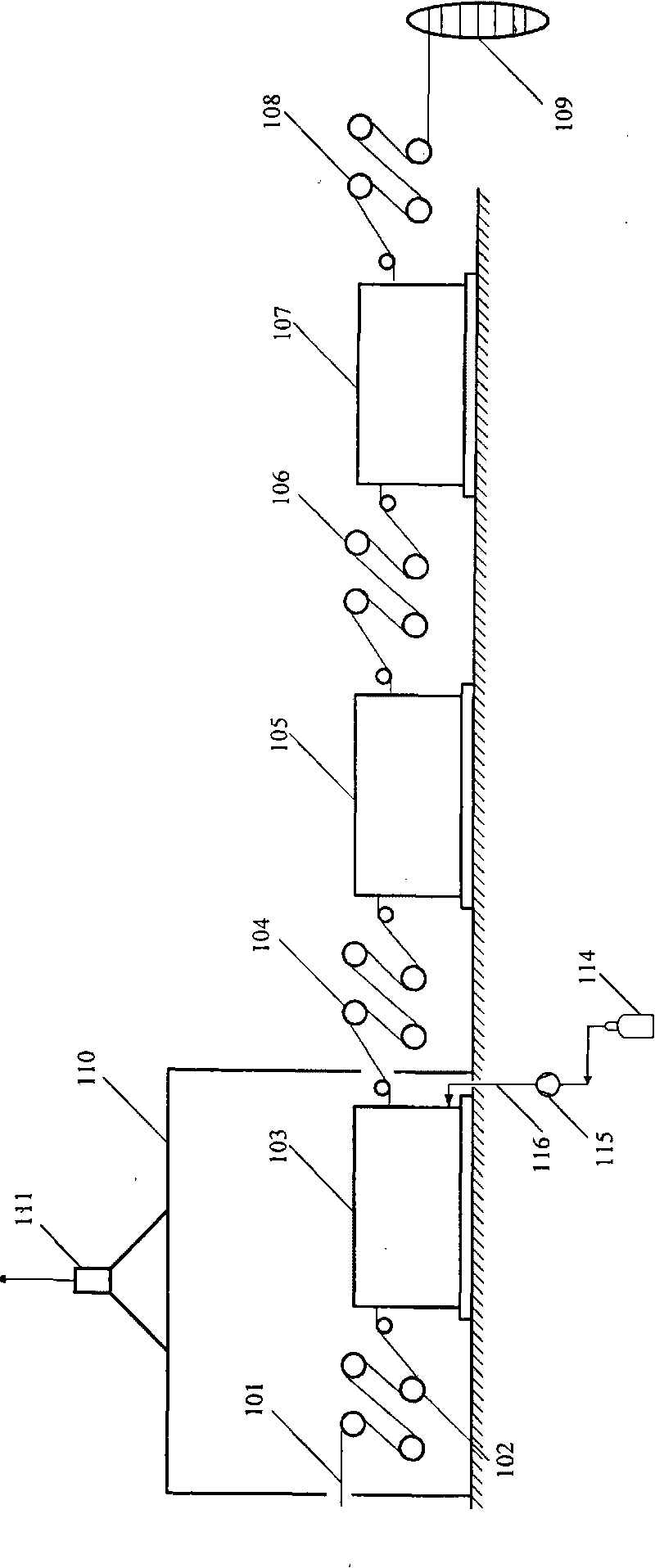

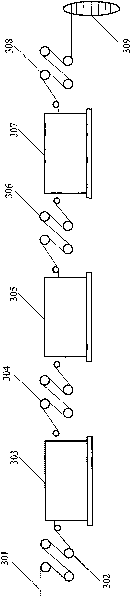

[0031] The hot drawing equipment and method for preparing ultra-high molecular weight polyethylene fibers proposed by the present invention are described in detail in conjunction with the accompanying drawings and examples as follows:

[0032] The invention proposes a hot drawing method for ultra-high molecular weight polyethylene fiber, which is characterized in that: the method includes performing multi-stage continuous drawing operation on the dried fiber, the direction of airflow in the fiber heating zone and the movement of the fiber The direction is the same; the temperature increases step by step, and the draw ratio decreases step by step. The ratio of the draw ratio of the last stage of hot drawing to that of the previous stage is 0.6 to 0.98, and the inlet and outlet of each stage The ratio of line speed at the end is 1:1.02~3; the gas temperature in the fiber heating zone is 125°C~150°C.

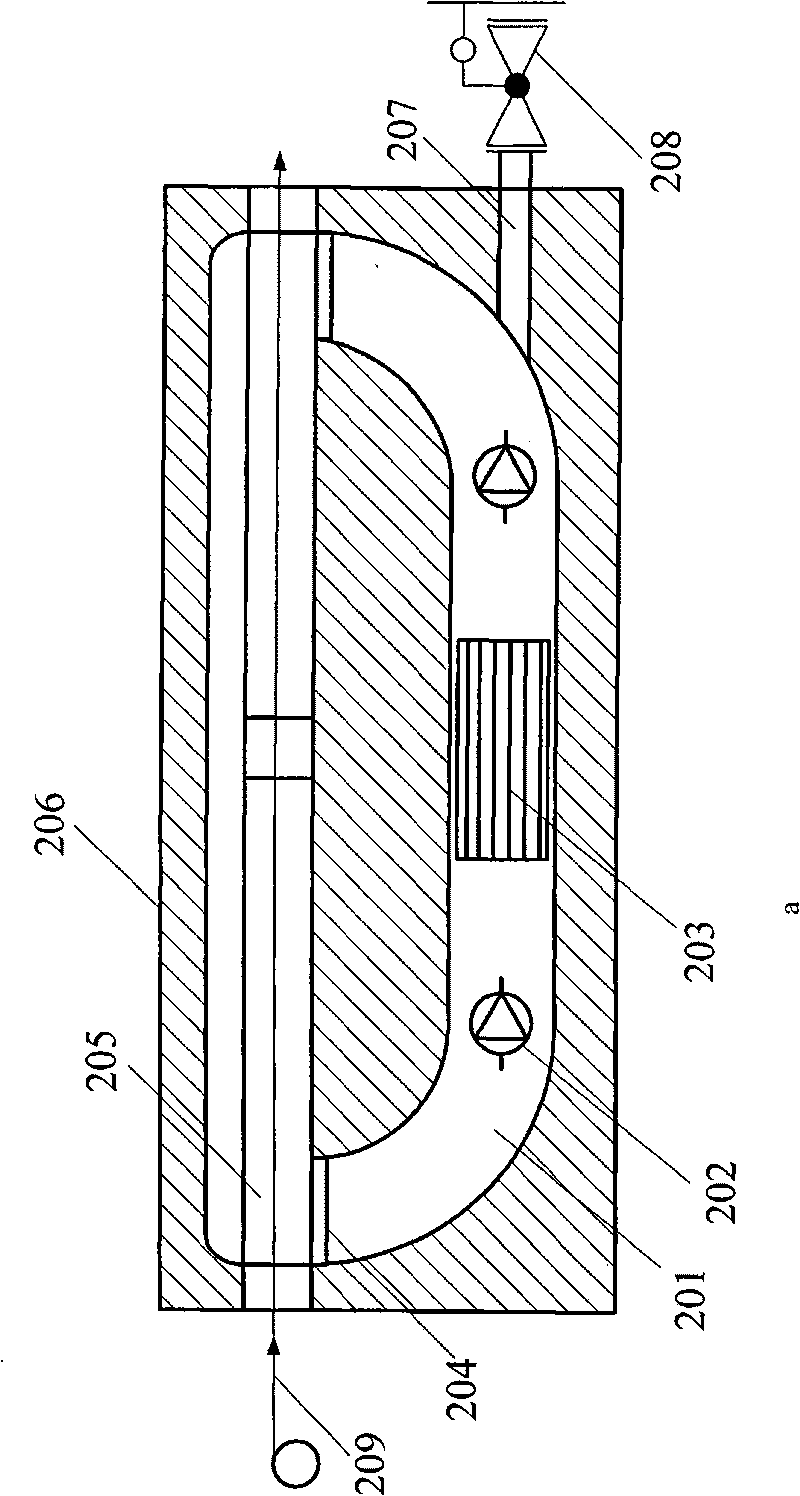

[0033] The present invention also proposes the thermal drawing process equipme...

Embodiment 1

[0054] The dried fiber enters the first-stage drafting machine with a line speed of 25m / min, then enters the first-stage hot drawing hot box with a temperature of 135°C, and then enters the second-stage drafting machine with a line speed of 31m / min. Then enter the second stage hot drawing hot box, the temperature of the hot box is 138 ℃, then enter the third stage drawing machine, the line speed is 35m / min. Enter the third stage hot drawing hot box, the temperature of the hot box is 145 ℃, then enter the fourth stage drawing machine, the line speed is 38m / min.

[0055] The drafting hot boxes are all 4.5 meters in length and are heated by induction. The first-stage drafting machine and the first-stage drafting hot box are all located in the sealed cover, and the upper part of the sealed cover is provided with an air outlet, and a fan is installed, and the air volume of the fan is not less than 1 cubic meter per second. An inert gas inlet is installed on the side lower part of...

Embodiment 2

[0057] The dried fiber enters the first-stage drafting machine with a line speed of 27m / min, then enters the first-stage hot drawing hot box, and the temperature of the hot box is 138°C, and then enters the second-stage drafting machine with a line speed of 38m / min. Then enter the second stage hot drawing hot box, the temperature of the hot box is 139 ℃, then enter the third stage drawing machine, the line speed is 47m / min. Enter the third stage hot drawing hot box, the temperature of the hot box is 145°C, then enter the fourth stage drawing machine, the line speed is 54m / min, and then enter the fourth stage drawing hot box, the temperature of the hot box is 147°C, Finally, it passes through the fifth-stage drafting machine with a line speed of 60m / min. Finally, it is wound and formed into a finished product. The length of the drafting hot box is 5 meters.

[0058] The drafting hot box adopts induction heating. The first-stage drafting machine and the first-stage drafting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com