Method for making mica paper by reinforcement of aramid short fiber and chemical pulping

A technology of aramid chopped fiber and reinforced chemistry, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, papermaking, etc., and can solve the problem of lack of natural mica sheet material strength, difficulty in increasing vehicle speed, mica paper Low strength and other problems to achieve the effect of reducing the probability of paper breakage, increasing the speed of the vehicle, and improving the insulation strength and dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

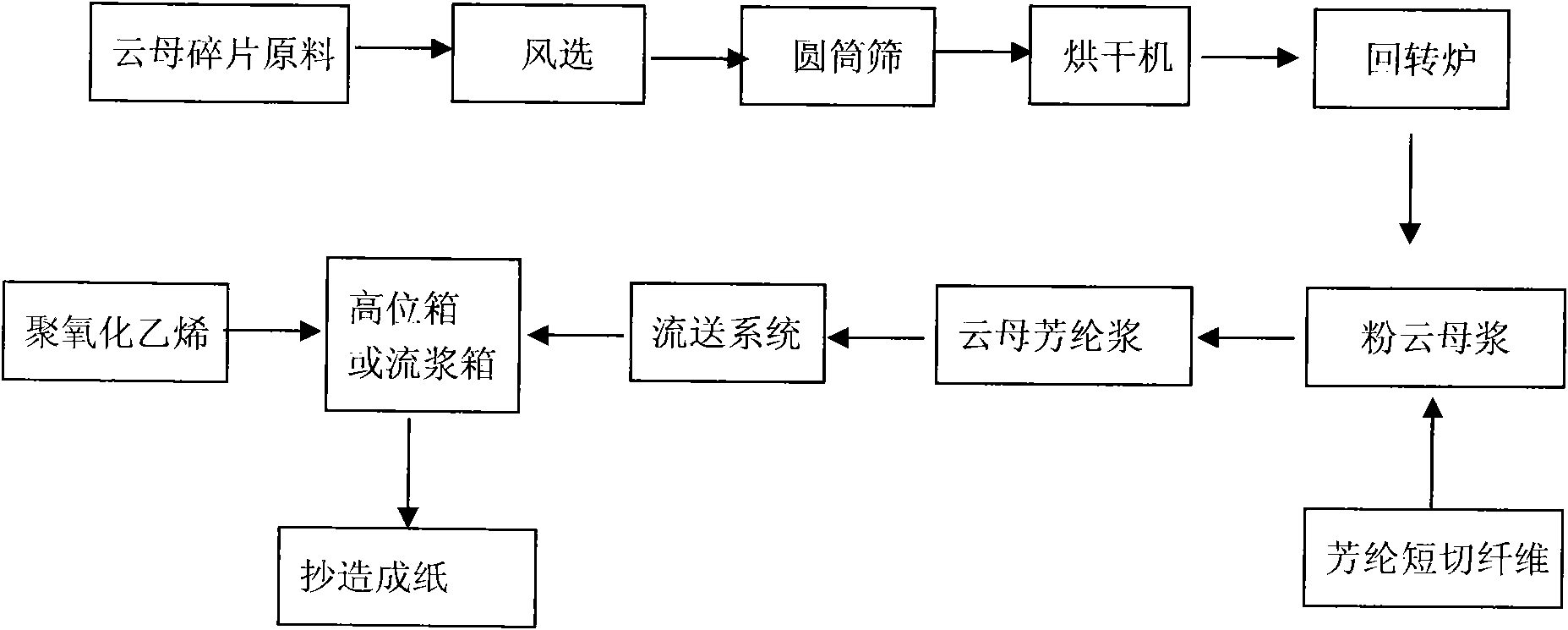

[0021] Clean the mica fragments to remove impurities, and then put them into the intermittently heated rotary furnace for calcination, so that the mica can lose part of the crystallization water in the crystal, so that the mica will expand significantly along the vertical direction of the cleavage plane and stratify, becoming loose and Soft, dipped in a certain concentration of acid-base solution to form mica sheets, and graded into chemically powdered mica pulp with a certain degree of beating. Add 3%-15% aramid fiber (relative to the mass ratio of mica chips) in the slurry. Prepare mica aramid fiber pulp, and use paper machine to make paper. The skeleton effect of aramid fiber improves the strength of mica paper. Specific steps are as follows:

[0022] (1) Sorting powder mica fragments, removing biotite, green mica and some associated impurities that cannot be used for making mica paper, and removing thick mica sheets with a thickness greater than 1.3mm.

[0023] (2) Wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com