Construction method for rock anchorage beam of underground workshop

A technology for underground workshops and construction methods, which is applied in excavation, infrastructure engineering, sheet pile walls, etc., can solve the problems of unsatisfactory repair effect, reducing the bearing capacity of rock anchor beams, affecting the anchoring of rock anchor beams and surrounding rock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The construction method of the rock anchor beam for the underground powerhouse provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

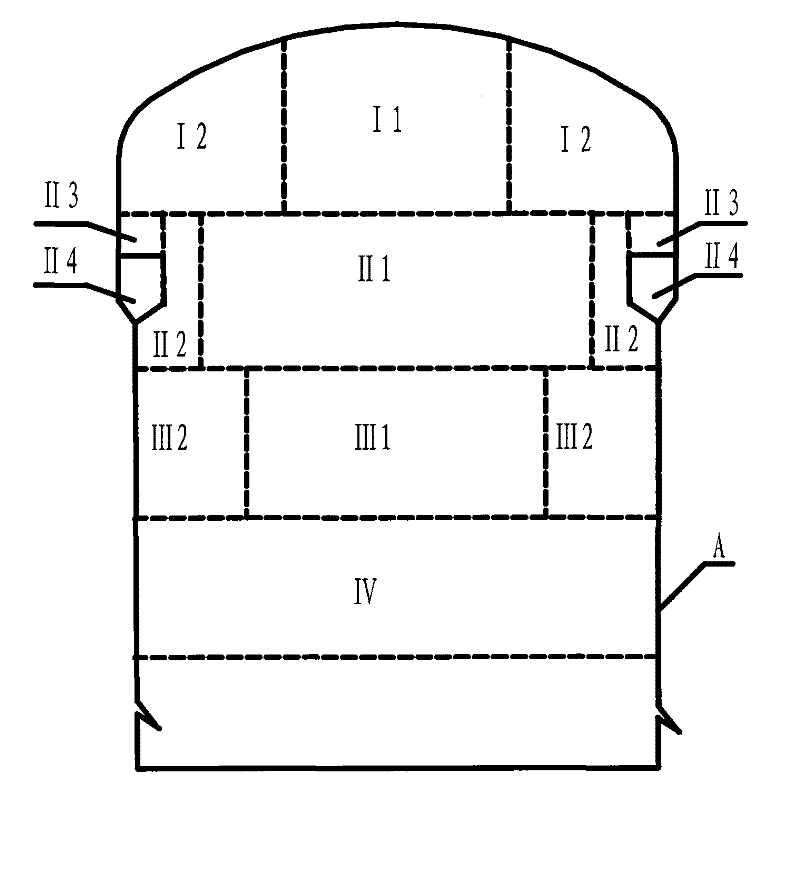

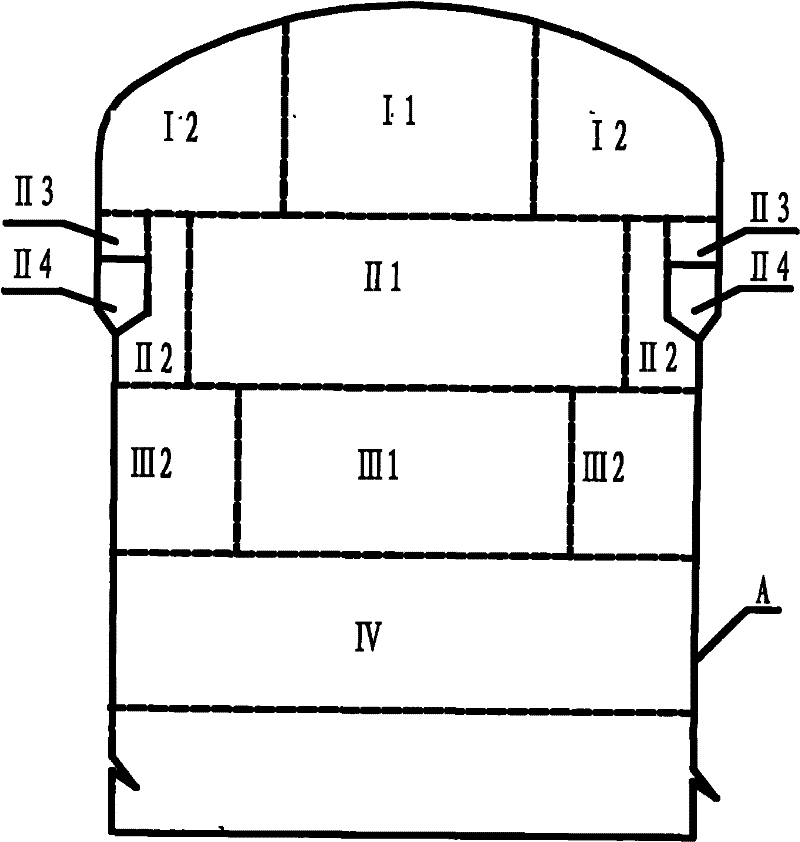

[0020] As shown in the accompanying drawings, the excavation depth of the underground powerhouse is generally about 50m, and the excavation is carried out in layers. In this embodiment, the actual construction exceeds four floors. The specific construction process is as follows:

[0021] (1) Construction of the first floor (arch part) of the underground powerhouse

[0022] The excavation of the first floor of the underground powerhouse generally adopts the method of excavating the middle pilot tunnel I 1 and expanding the excavation I 2 on both sides.

[0023] (2) Construction of the second floor of the underground workshop

[0024] The second floor of the underground powerhouse is usually excavated in four parts. The part above the rock anchor beam is II 3, the protective lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com