Rectification speed increasing tower used for vertical axis wind turbine

A wind power generator, vertical axis technology, applied to wind power generators, wind power generators at right angles to the wind direction, motors, etc., can solve the problem of unsuitable applications for densely populated areas with the greatest power demand, low wind speed at start-up, wind energy utilization efficiency, and blade design And the difficulty of manufacturing and other issues, to achieve the effect of helping landscape design, improving the utilization rate of wind energy, and preventing birds from being harmed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

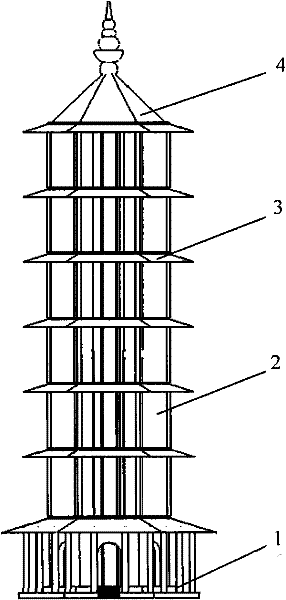

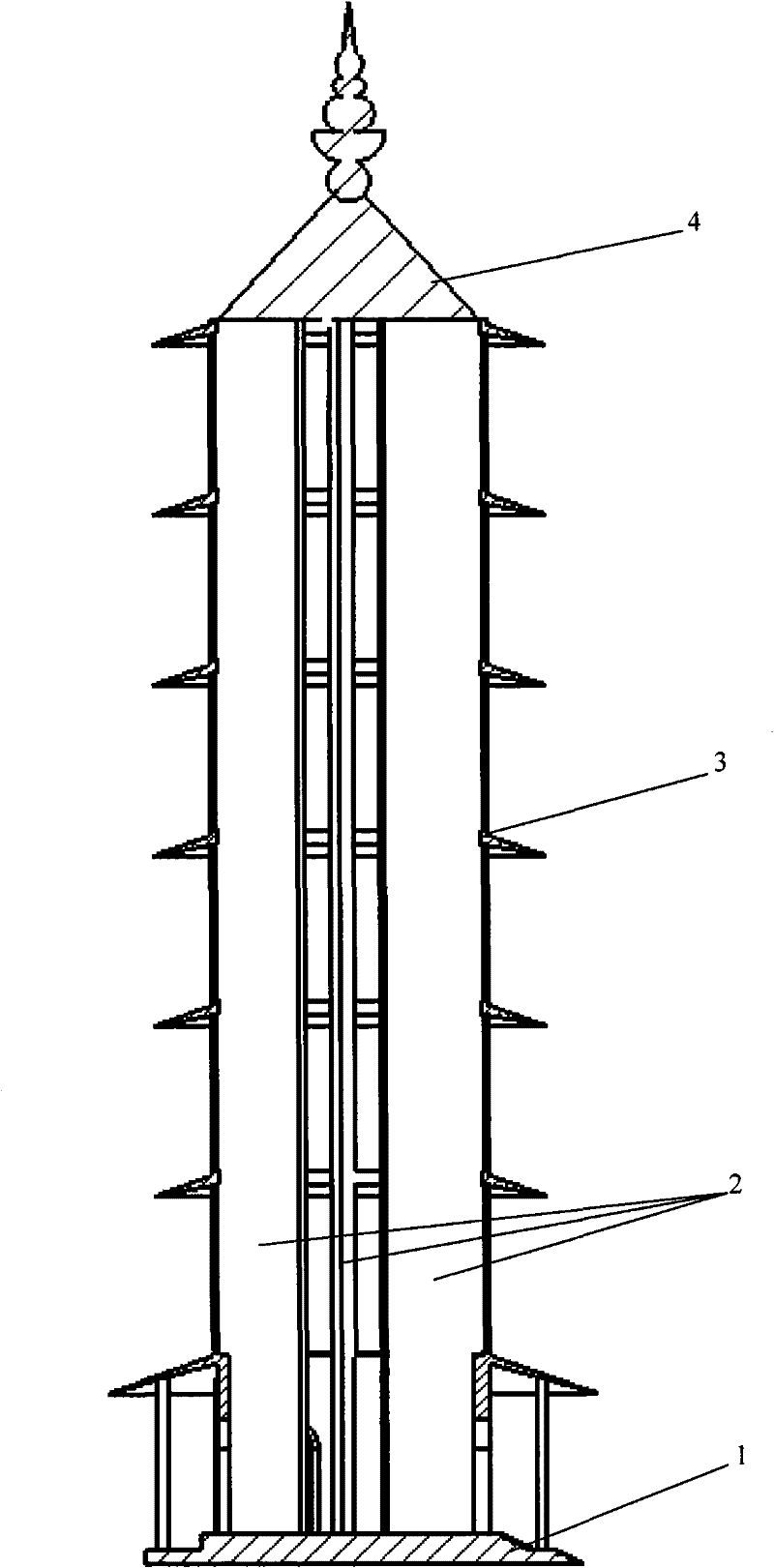

[0037] Specific implementation example 1: (fixed deflector type rectification speed-increasing tower)

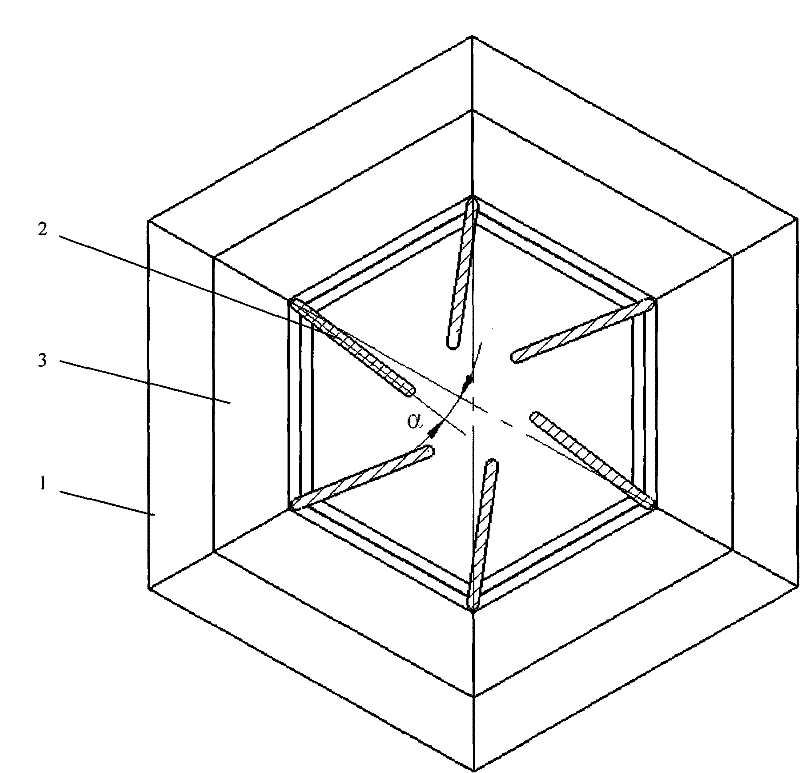

[0038] Fixed deflector type rectification growth tower such as figure 2 , image 3 As shown, the deflector is composed of a group (more than 4 pieces) of flat or curved plates, the upper end of which is connected to the tower eaves 3 or the tower top 4, and its lower end is connected to the tower base 1 or the tower eaves 3, and the deflector The groups are distributed in the circumferential direction with the tower center as the center and form a certain angle α with the radial direction (such as image 3 shown), the value range of α is 0-23°. The center of the tower presents a hollow columnar cavity, which is used to house vertical axis wind turbines.

specific Embodiment 2

[0039] Specific implementation example 2: (implementation scheme of deflector rotary adjustment method)

[0040]As shown in Figure 7(a), each deflector 2 is composed of a fixed part 21 and a movable part 22, wherein the upper end of the fixed part 21 is connected with the tower top 4, the lower end is connected with the tower base 1, and the movable part 22 passes through The rotating shaft 23 is connected with the fixed part 21, and the movable part 22 of the deflector can rotate around the rotating shaft 23 driven by external force. The adjustment method of the movable part of the deflector is shown in Figure 7(b). The motor 27 is connected to the reducer 25 through the coupling 26, the reducer is connected to the rotating shaft 23, and the rotating shaft 23 is controlled by the motor to rotate, thereby driving the movable part 22 to rotate. .

[0041] Assuming that the wind direction is from left to right, the left wind tunnel shown in Figure 7(a) is in the windward direct...

specific Embodiment 3

[0042] Specific implementation example 3: (implementation scheme of deflector push-pull adjustment mode)

[0043] As shown in Figure 8 (a), the deflector 2 is composed of a fixed part 21 and a movable part 22, wherein the lower part of the fixed part 21 is connected with the base 1, and the upper part is connected with the tower top 4, and the fixed part 21 and the movable part 22 The space is connected by a hinge 23, and the movable part 22 can rotate under the drive of external force. The adjustment method of the movable part of the deflector is shown in Figure 8 (b). The motor 27 is connected to the lead screw 28 through a coupling, and the lead screw is equipped with a sliding guide rail 29. The table 29 is slidable on the guide rod 25 . The motor 27 drives the lead screw 28 to rotate to drive the movable workbench 29 to move linearly along the guide rod 25, and the workbench 29 pushes the connecting rod 24 to move, thereby driving the movable part 22 of the deflector to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com