Motor control device, drive device, and hybrid drive device

A control device and motor technology, applied in the direction of motor generator control, AC motor control, control of electromechanical transmission, etc., can solve problems such as loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

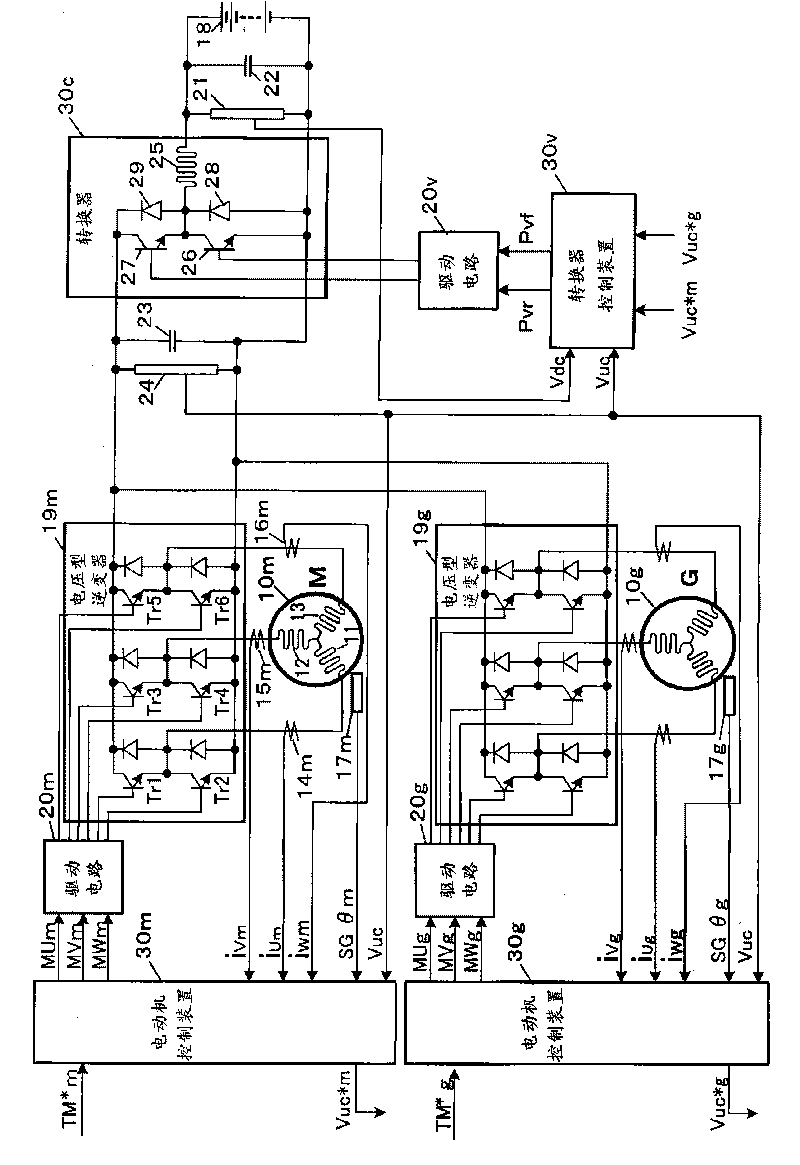

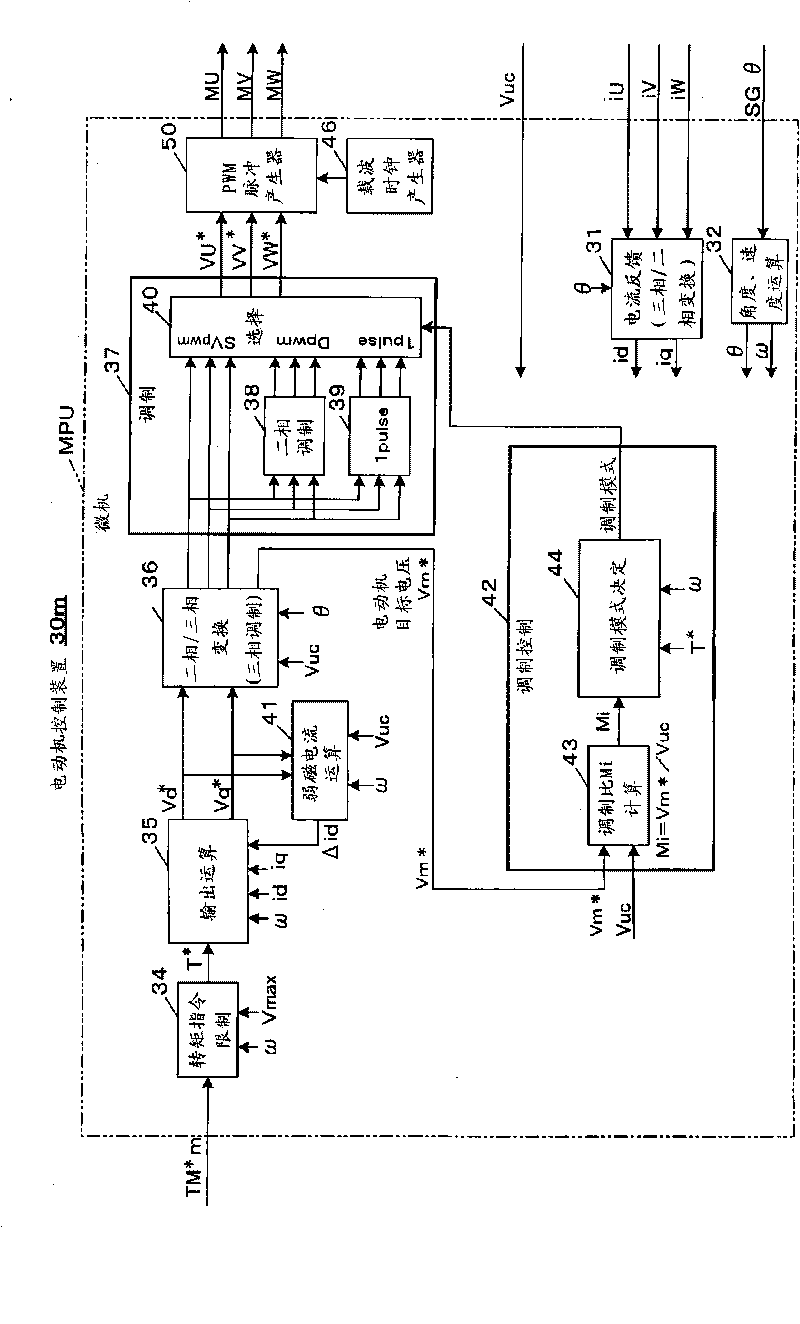

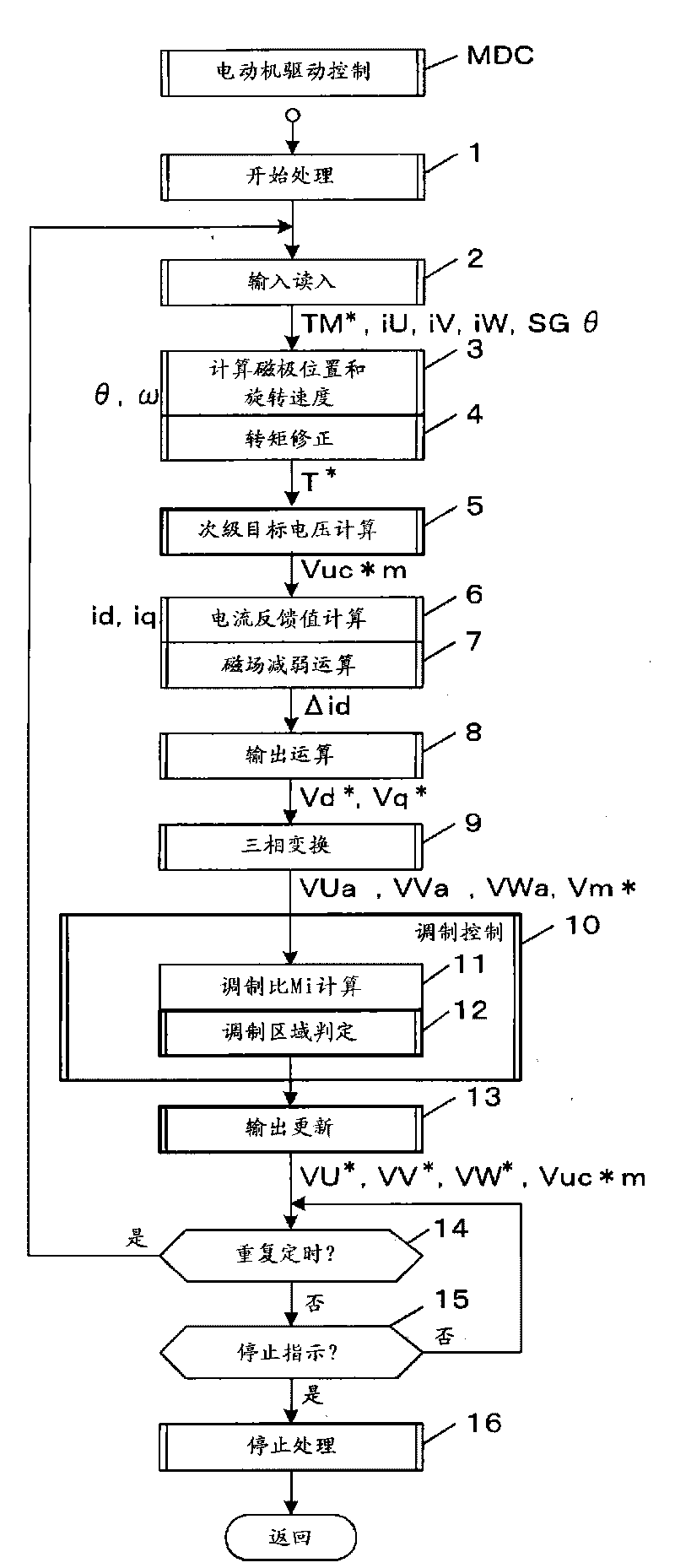

[0074] figure 1 The outline of the first embodiment of the present invention is shown. The electric motor 10m as the motor to be controlled is, in this embodiment, a permanent magnet synchronous motor for rotationally driving the wheels mounted on the vehicle. A permanent magnet is built into the rotor, and U-phase, V-phase, and The three-phase coils 11 to 13 of the W phase. The voltage source inverter 19m supplies electric power of the battery 18 on the vehicle to the electric motor 10m. A rotor of a resolver 17m for detecting the magnetic pole position of the rotor is connected to the rotor of the motor 10m. The resolver 17m generates an analog voltage (rotation angle signal) SGθm indicating the rotation angle of the motor, and applies it to the motor control device 30m.

[0075] A primary-side capacitor 22 is connected to the battery 18 serving as a storage battery of the vehicle when the power supply of the electric parts of the vehicle is turned on, and constitutes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com