Novel method and device for processing boat exhaust gas

A technology for ship exhaust and treatment devices, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem that carbon, nitrogen and sulfur pollutants cannot be removed at the same time, the pollutant removal efficiency is low, and the equipment cost is large. problem, to achieve the effect of convenient installation, good removal effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Implementation example one is an embodiment of the method of the present invention; implementation example two is an embodiment of the device of the present invention.

[0037] Implementation example one

[0038] A method for treating ship tail gas, characterized in that it comprises the following processes:

[0039] A. The process of generating cleaning water: fresh seawater is processed to produce efficient cleaning water;

[0040] B. Atomization process: the cleaning water obtained in the A process enters the atomization device for atomization to obtain aerosol;

[0041] C. Gas-liquid reaction process: send the aerosol obtained in the B process into the gas-liquid reaction device to react with the exhaust gas of the ship, thereby removing the gas pollutants in the exhaust gas; when the aerosol contacts the solid particles in the exhaust gas, it will be on the solid particles Form a liquid, and then settle into the bottom of the reaction device together;

[0042] D...

Embodiment 2

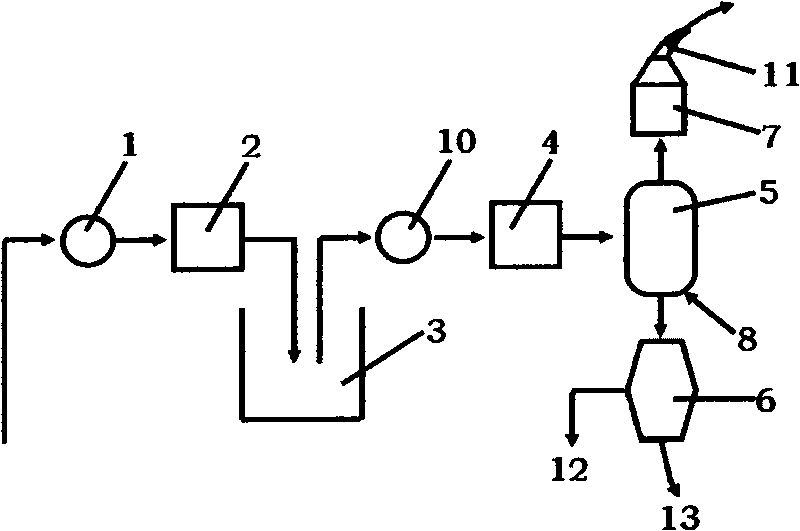

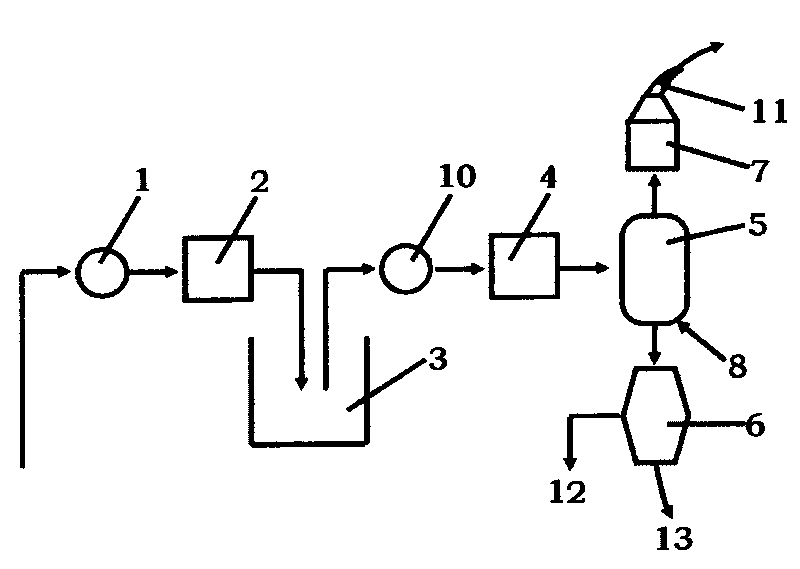

[0046] See figure 1 And reference implementation example 1, a new type of ship tail gas treatment device, characterized in that it includes: a pump 1, an electrocatalytic treatment unit 2, a storage tank 3, an atomization device 4, a gas-liquid reaction device 5, and a solid-liquid separation device 6 , condensing reflux device 7, waste gas inlet 8 and pump 10; the outlet of water pump 1 is connected with the inlet of electrocatalytic treatment unit 2, the outlet of electrocatalytic treatment unit 2 is connected with storage tank 3 through pipeline, and one end of pump 10 is connected with storage tank 3 The tank 3 is connected, and the other end is connected to the inlet of the atomization device 4, the outlet of the atomization device 4 is connected to the liquid input end of the gas-liquid reaction device 5, and the exhaust gas inlet 8 is connected to the gas input end of the gas-liquid reaction device 5, and the gas-liquid reaction The gas output end of the device 5 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com