Prepration method of Pt/TiO2 compound catalyst for low temperature combustion of methanol

A composite catalyst, low-temperature combustion technology, applied in physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc., to achieve the effects of simple preparation method, high catalytic activity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one: concrete steps are:

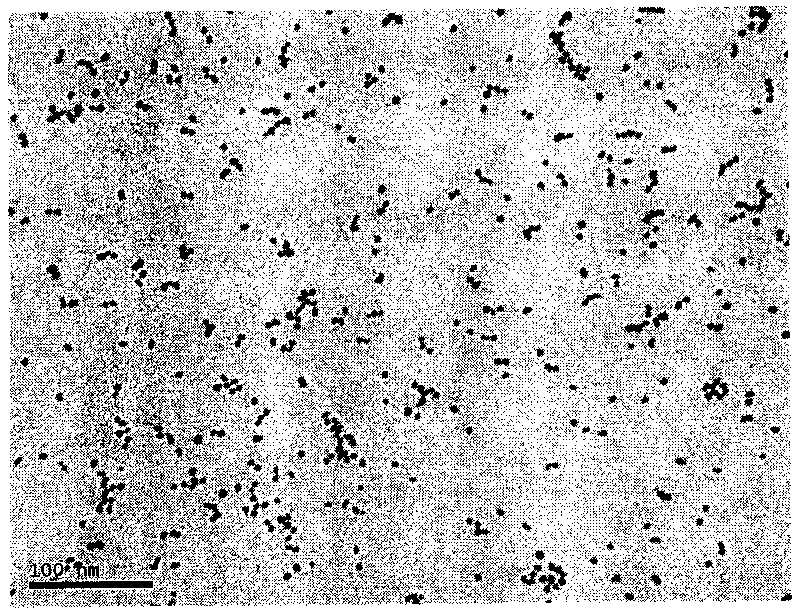

[0022] 1. First configure 0.08mol / L H 2 PtCl 6 aqueous solution and 0.03mol / L PVP (polyvinylpyrrolidone) glycol solution. 0.1122 g NaNO 3 Add it to 35mL PVP ethylene glycol solution to dissolve, raise the temperature to 160°C until the solution slightly boils under electromagnetic stirring, and quickly inject 3~5mL H with a pipette 2 PtCl 6 Aqueous solution, reflux reaction for 5 to 20 minutes, the solution turns from light yellow to deep black, and the reaction stops. After cooling, wash with a large amount of acetone solution, and centrifuge at 3900 rpm for 1 minute to obtain a black product. Add 5-10 mL of ethanol solution, ultrasonically disperse for 10-30 min, and finally obtain a uniform and monodisperse nano-Pt particle A solution.

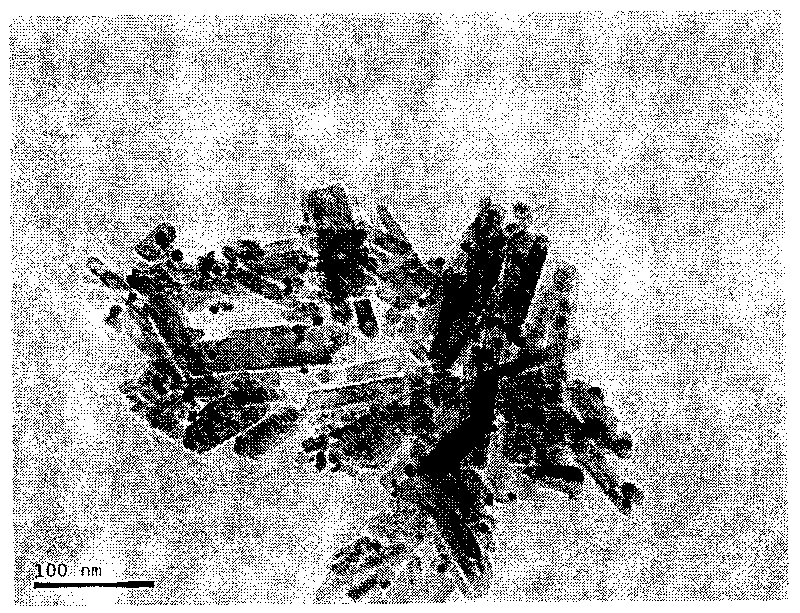

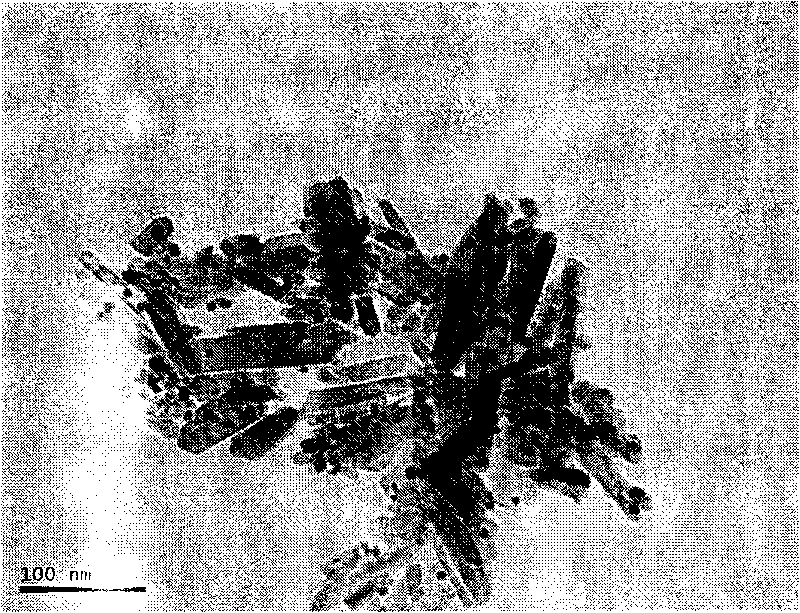

[0023] 2. Add 5mL TiCl 4 Slowly add it dropwise into 10-30mL ice water, after the vigorous hydrolysis tends to be stable, dilute to 85mL with deionized water, and stir electromagnetically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com