Apparatus for stably maintaining sludge micro-bulking for saving energy in biological denitrification technology and method thereof

A biological denitrification and micro-expansion technology, which is applied in chemical instruments and methods, biological water/sewage treatment, sustainable biological treatment, etc., can solve the problems of high energy consumption in aeration operation and the inability to prevent malignant sludge expansion, etc., to achieve Saving aeration energy consumption, achieving balanced growth, and stably maintaining the effect of sludge micro-expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

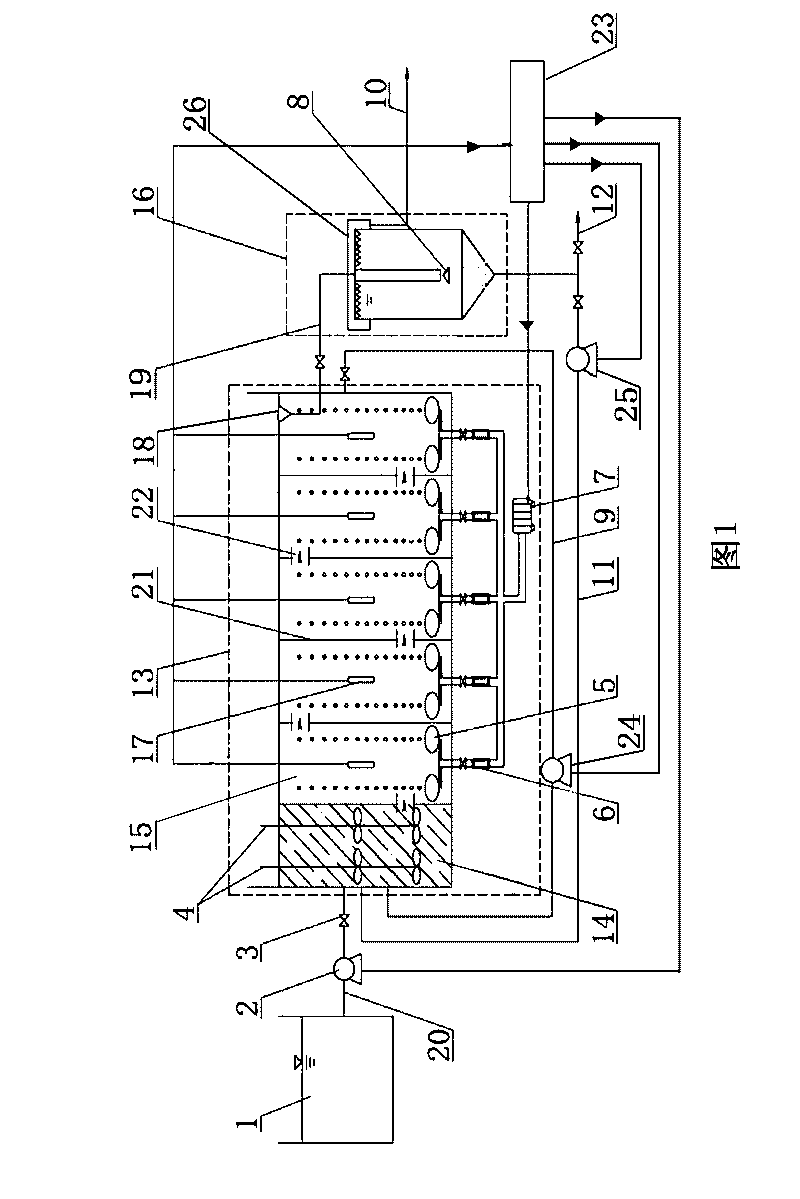

[0025] Embodiment one sees figure 1 As shown, a biological denitrification process stably maintains the sludge micro-expansion device to realize energy saving. According to the order from the raw water inlet to the clean water outlet, the water inlet tank 1, the reactor 13 and the secondary sedimentation tank 16 are arranged in sequence. The water inlet tank 1 is connected to the reactor 13 through the peristaltic pump 2, the water inlet pipe 20 and the valve 3, the outlet hole 18 on the reactor 13 is connected to the secondary sedimentation tank 16 through the clean water pipeline 19 and the valve, and the middle part of the reactor 13 is connected to the nitrifying liquid pipeline through the return flow 9. The second peristaltic pump 24 and the valve are connected to the anoxic compartment 14. The separator 8 is set in the secondary settling tank 16. The water inlet pipe of the secondary settling tank is in the center, and the water outlet weir 26 overflows around the periph...

Embodiment 1

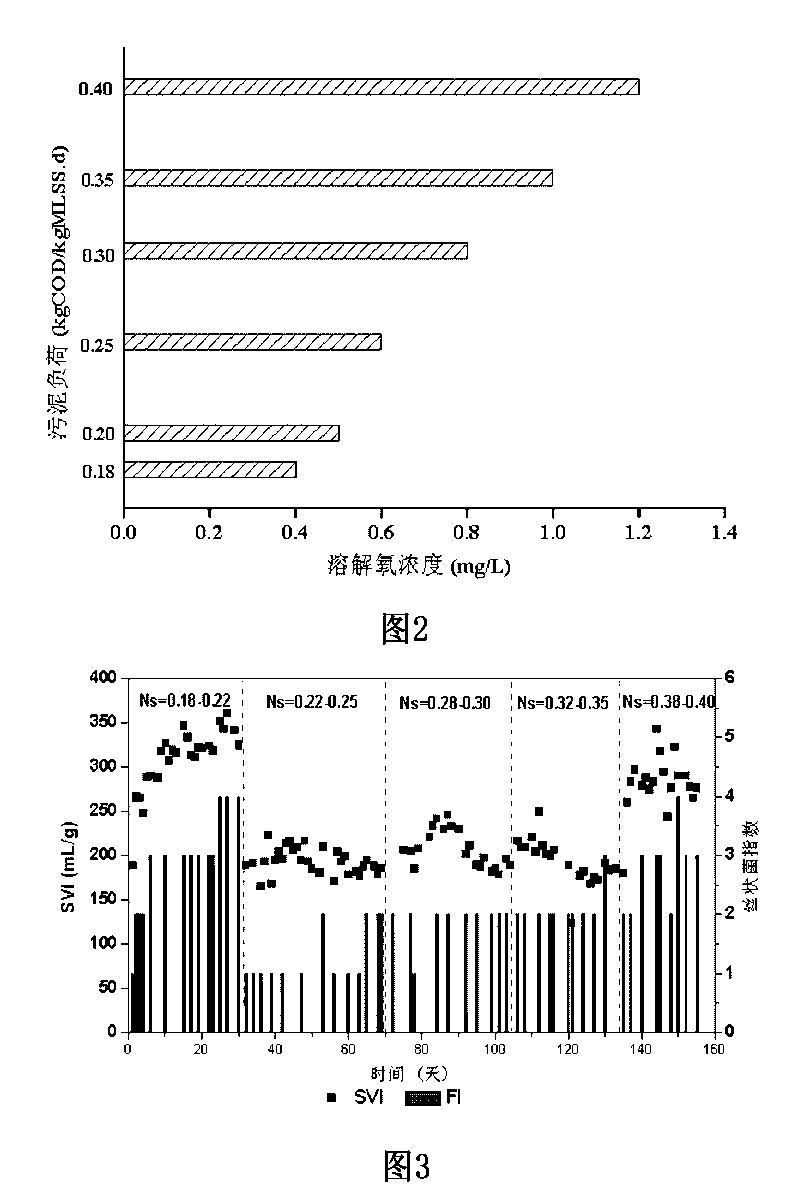

[0029] The A / O process is used to treat campus domestic sewage. The mixed liquid suspended solids concentration (MLSS) in the aeration tank is maintained between 2500~3500mg / L, the average temperature of the reactor is 25°C, the internal circulation ratio is 150%, and the sludge reflux is 100%. . The volume ratio between the anoxic zone and the aerobic zone is 1:5, and the load is changed by changing the influent flow rate. At the beginning of each load, high dissolved oxygen is used to stabilize the operation, and then the aeration volume of each compartment in the aerobic zone is adjusted to Maintain the average DO in the reactor at various levels. After summarizing the test data, it is found that the relationship between the optimal dissolved oxygen and the sludge load is required to achieve an ammonia nitrogen removal rate of more than 70% and maintain an SVI between 150 and 250mL / g under different influent load conditions. attached figure 2 shown. High loads correspon...

Embodiment 2

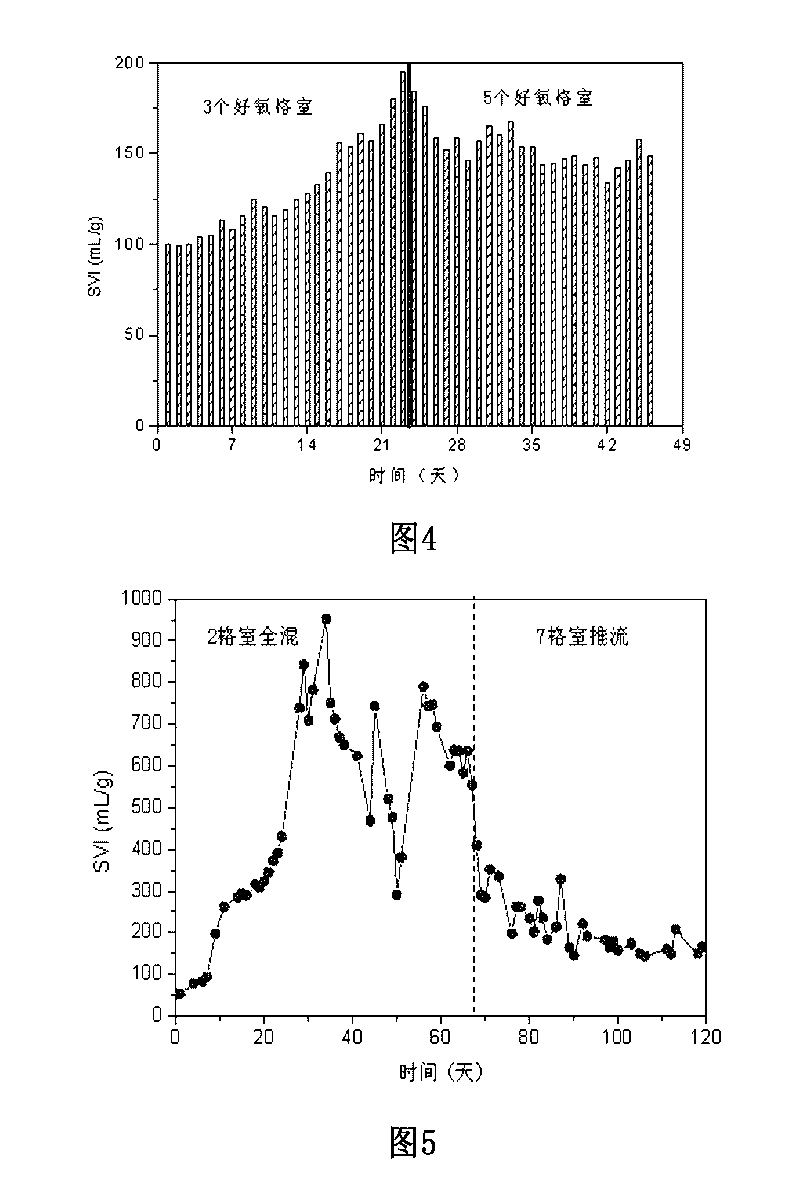

[0030] Embodiment two see image 3 As shown, it shows the effect diagram of sludge micro-expansion maintenance under different loads and optimized DO. Under optimized DO conditions, the changes of SVI and filamentous bacteria index (FI) in the system when the sludge micro-expansion state is stably maintained curve. A device that can stably maintain the micro-expansion of sludge in sewage treatment to achieve energy saving (such as figure 1 shown) to maintain sludge micro-expansion at the optimized DO concentration. The raw water is campus domestic sewage. The concentration of mixed liquid suspended solids (MLSS) in the aeration tank is maintained at 2500~3500mg / L. The average temperature of the reactor is 25°C, the internal circulation ratio is 150%, and the sludge return ratio is 100%. The volume ratio of the anoxic zone and the aerobic zone is 1:5, and the load is changed by changing the influent flow rate. During the test, the treated water volume is 170~320L / d.

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com