Pigment dispersion method, pigment mixture, light-cured ink and thermo-cured ink

A pigment dispersion and mixture technology, which is applied in the direction of pigment slurry, ink, organic dyes, etc., can solve the problems of high viscosity, particle size not meeting the requirements, wide particle size distribution range, etc., and achieve low viscosity, short process cycle, The effect of a narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

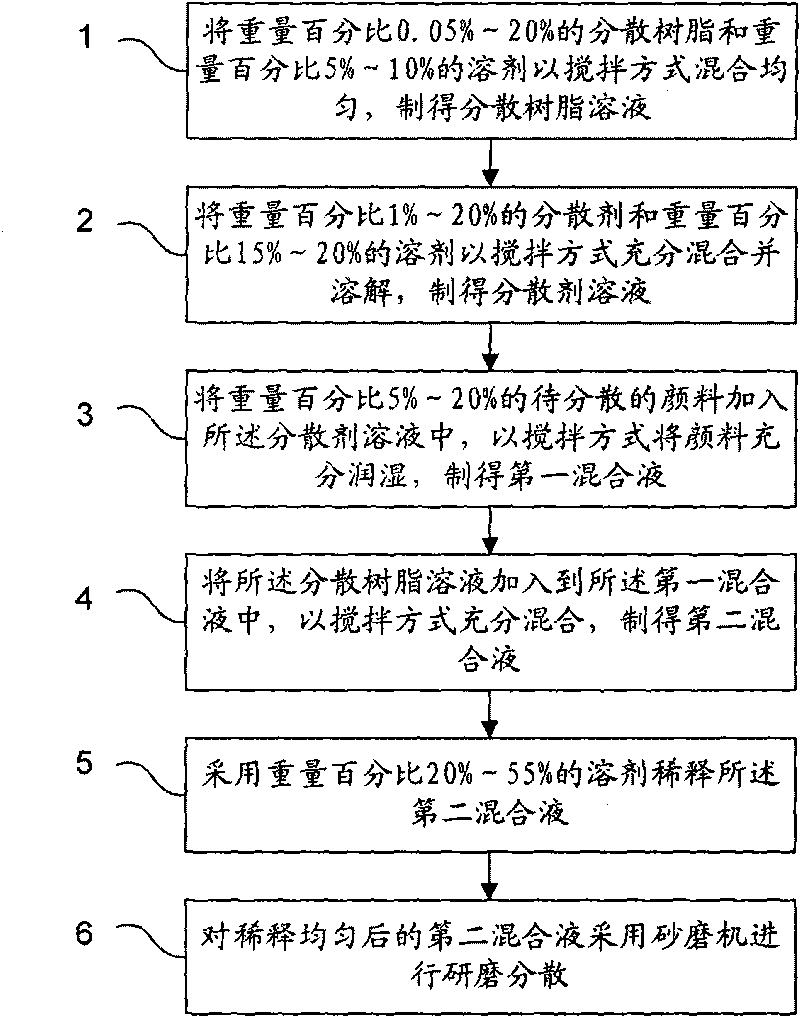

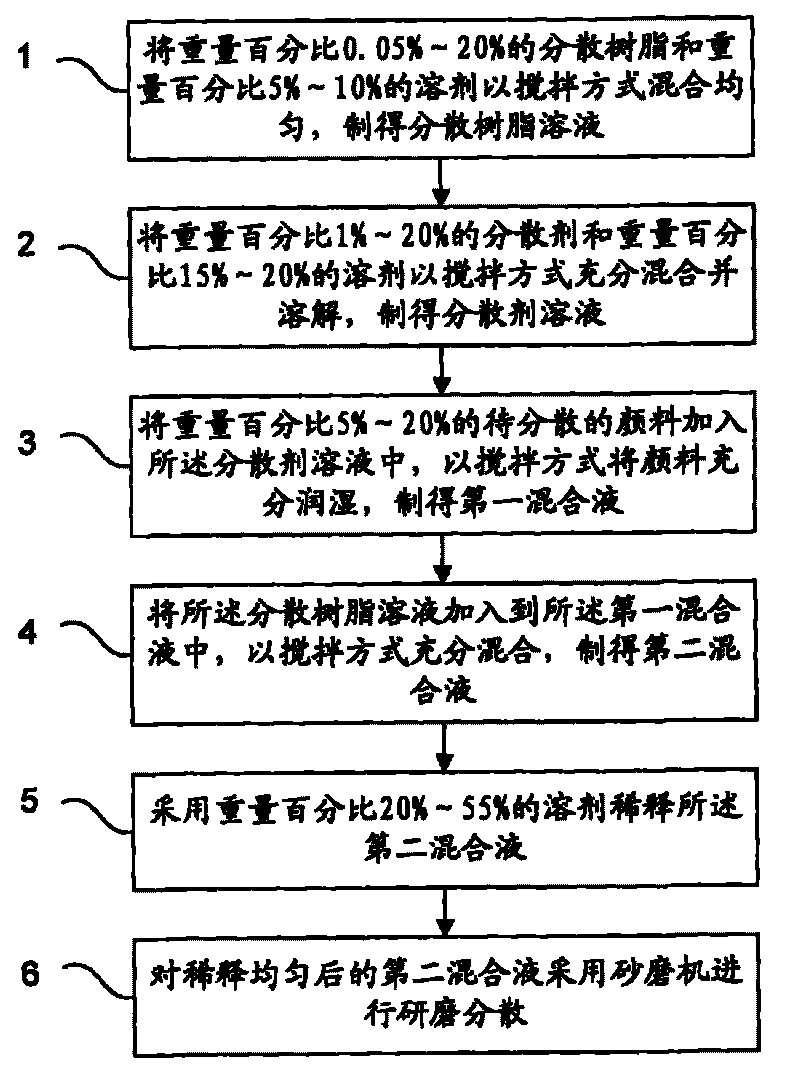

[0057] Step 11, mixing 40 parts by weight of the dispersed resin and 50 parts by weight of the solvent in a high-speed stirring manner to obtain a dispersed resin solution;

[0058] Step 12, fully mixing and dissolving 83 parts by weight of the dispersant and 110 parts by weight of the solvent in a high-speed stirring manner to prepare a dispersant solution;

[0059] Step 13, adding 100 parts by weight of the pigment to be dispersed into the dispersant solution, and fully wetting the pigment by high-speed stirring to prepare the first mixed solution;

[0060] Step 14, adding the dispersing resin solution into the first mixed solution, and fully mixing with high-speed stirring to prepare a second mixed solution;

[0061] Step 15, adding 263.5 parts by weight of solvent into the second mixed solution to dilute the second mixed solution;

[0062] Step 16: Grinding and dispersing the uniformly diluted second mixed solution with a sand mill.

[0063] Table 1a shows the situation ...

no. 2 example

[0069] Step 21. Mix 40 parts by weight of dispersing resin, 3.5 parts by weight of wetting agent and 50 parts by weight of solvent in a high-speed stirring manner to prepare a dispersed resin solution;

[0070] Step 22, fully mixing and dissolving 75 parts by weight of dispersant and 110 parts by weight of solvent in a high-speed stirring manner to prepare a dispersant solution;

[0071] Step 23, adding 100 parts by weight of the pigment to be dispersed into the dispersant solution, and fully wetting the pigment by high-speed stirring to prepare the first mixed solution;

[0072] Step 24, adding the dispersed resin solution into the first mixed liquid, and fully mixing with high-speed stirring to obtain a second mixed liquid;

[0073] Step 25, adding 271.5 parts by weight of solvent to the second mixed solution to dilute the second mixed solution;

[0074] Step 26: Grinding and dispersing the uniformly diluted second mixed solution with a sand mill.

[0075] Table 2a shows t...

no. 3 example

[0082] Step 31, mixing 40 parts by weight of the dispersion resin and 50 parts by weight of the solvent uniformly in a high-speed stirring manner to prepare a dispersion resin solution;

[0083] Step 32, fully mixing and dissolving 40.9 parts by weight of dispersant and 110 parts by weight of solvent in a high-speed stirring manner to prepare a dispersant solution;

[0084] Step 33, adding 100 parts by weight of the pigment to be dispersed into the dispersant solution, and fully wetting the pigment by high-speed stirring to prepare the first mixed solution;

[0085] Step 34, adding the dispersed resin solution into the first mixed solution, and fully mixing with high-speed stirring to prepare a second mixed solution;

[0086] Step 35, adding 336 parts by weight of solvent to the second mixed solution to dilute the second mixed solution;

[0087] Step 36: Grinding and dispersing the uniformly diluted second mixed solution with a sand mill.

[0088] Table 3a shows the situatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com