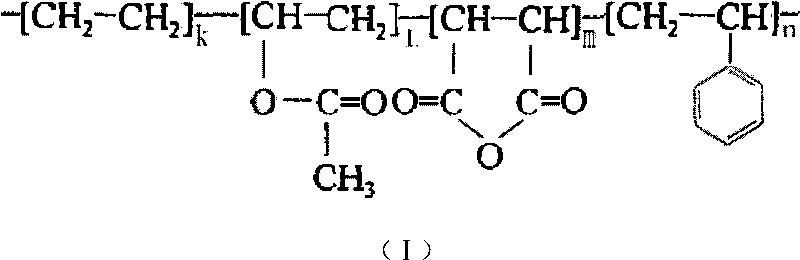

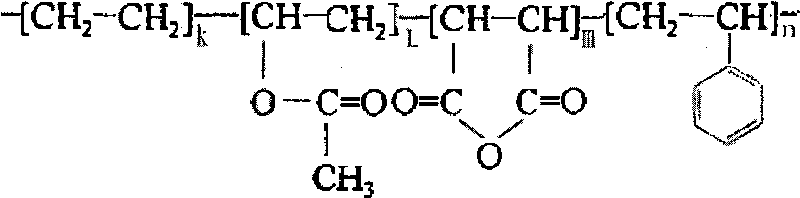

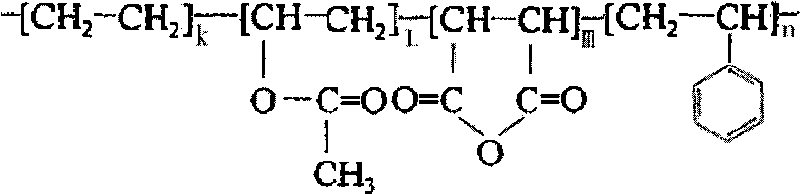

Biodiesel lower-temperature fluidity improver and preparation method thereof

A low-temperature fluidity, biodiesel technology, used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of ineffective cooling point improvement, poor biodiesel susceptibility, and limited biodiesel applications. The effect of preventing crystal formation, improving susceptibility, lowering freezing point and freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Dissolve 28g (1mol) of ethylene, 86g (1mol) of vinyl acetate, 98g (1mol) of maleic anhydride, and 104g (1mol) of styrene in 650g of toluene, mix well, let stand for 30min, and add 3.5g of azobisiso Butyronitrile initiator, after reacting 2h under the temperature of 60 ℃, under 8Mpa pressure, add the mixed solution of the ethanol containing 1wt%NaOH and water (V / V=1) of 31g to stop polymerization, polymer product removes solvent and does not have After the reacted monomers are polymerized, they are washed with water, purified and dried to obtain the biodiesel low-temperature fluidity improver A of the present invention.

Embodiment 2

[0016] Dissolve 28g (1mol) of ethylene, 86g (1mol) of vinyl acetate, 98g (1mol) of maleic anhydride, and 104g (1mol) of styrene in 1200g of toluene, mix well, let stand for 60min, and add 9g of azobisisobutyl Nitrile initiator, after reacting for 1h at a temperature of 100°C and under a pressure of 8Mpa, add 15g of a mixed solution of ethanol / water (V / V=1) containing 1wt%NaOH to terminate the polymerization, and the polymerization product is desolvated and unreacted After polymerizing the monomers, the biodiesel low temperature fluidity improver B of the present invention is obtained by washing, purifying and drying with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com