Nanometer grinding process and nanometer grinding liquid

A nano-grinding and grinding fluid technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of difficult to remove heat, poor fluidity of solid materials, difficult grinding process, etc., and achieve processing quality and economic benefits. The effect of improving, reducing abrasive wear, high application value and market prospect

Inactive Publication Date: 2013-02-06

QINGDAO TECHNOLOGICAL UNIVERSITY

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the poor fluidity of solid matter, it is difficult to participate in the grinding process and it is difficult to take away heat, so it has not been paid attention to.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

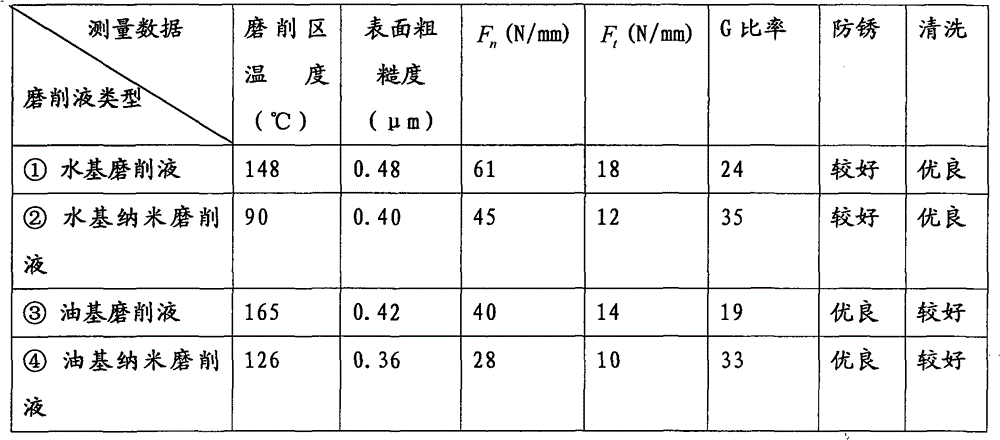

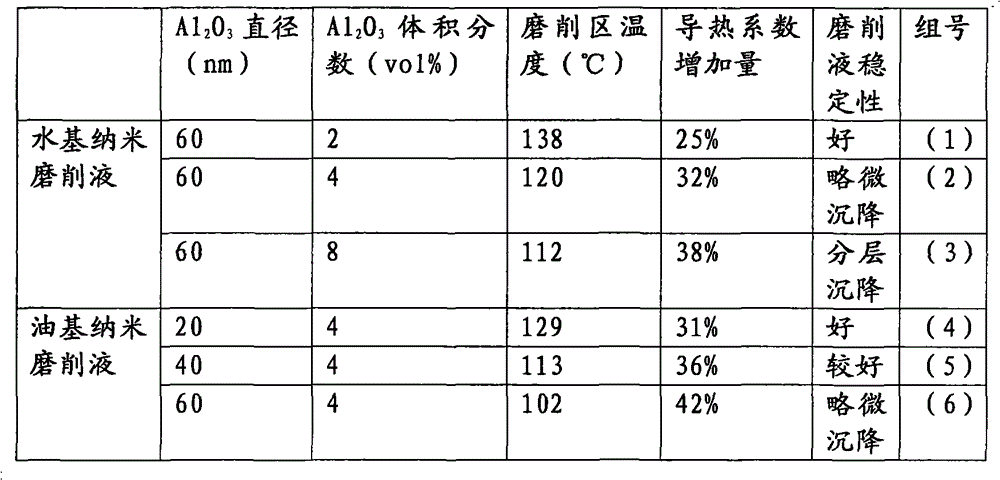

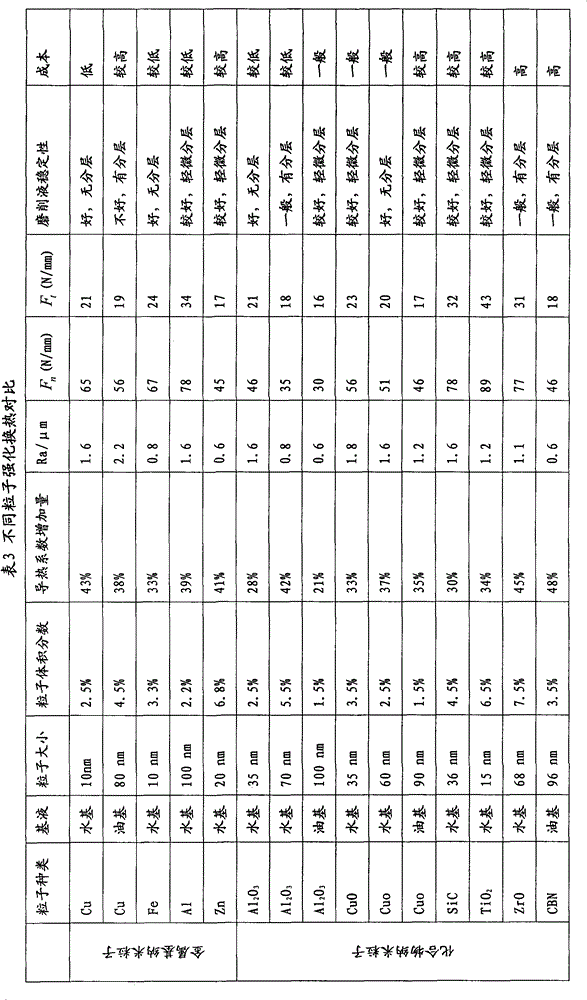

[0020] In order to verify the effect of nano grinding fluid, we have done a lot of experiments. The comparative experiment of nano-grinding fluid and existing grinding fluid, the formulation of nano-grinding fluid is optimized, including material, particle size, content, preparation method, etc. Now select two specific experiments and one experimental data statistical data to illustrate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to a machining method and a material, in particular to a nanometer grinding process and nanometer grinding liquid. In the nanometer grinding process, the nanoscale particles of solid matter are added into the grinding process; the nanometer grinding liquid is formed by mixing the nanoscale particles of solid matter and fluidic grinding liquid. The invention has the following beneficial effect: compared with the existing water-base or oil-base grinding liquid, the nanometer grinding liquid has greatly lowered indexes, such as grinding zone temperature, surface roughness, grinding resistance, grinding tool loss and the like; machining quality and economic benefit are obviously improved, and thus the invention has higher application value and market prospect.

Description

technical field [0001] The invention belongs to a mechanical processing method and material, namely a nano-grinding process and a nano-grinding liquid. Background technique [0002] Grinding is an important precision machining method, which is mainly used to improve the surface accuracy and surface integrity of the workpiece. However, the thickness of the chip layer in the grinding process is relatively thin, and the difference is tens to hundreds of times compared with cutting. Such a small cutting thickness will make the specific cutting force very large, the specific energy is very high, and a large amount of heat is generated, of which about 60%-95% of the heat is transferred to the workpiece, and less than 10% of the heat is carried away by the chips. The heat introduced into the workpiece is often too late to be introduced into the depth of the workpiece during the grinding process, and it gathers on the surface layer of the workpiece to form a local high temperature....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M125/04C10M125/10

Inventor 李长河侯亚丽刘占瑞杜超房赞赵婷婷

Owner QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com