Improved method for leaching magnesium-containing ore

A magnesium ore, leaching technology, applied in the direction of improving process efficiency, magnesium hydroxide, etc., can solve the problems of energy consumption, high equipment requirements, and environmental pollution again, and achieve the effect of reducing pollution and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

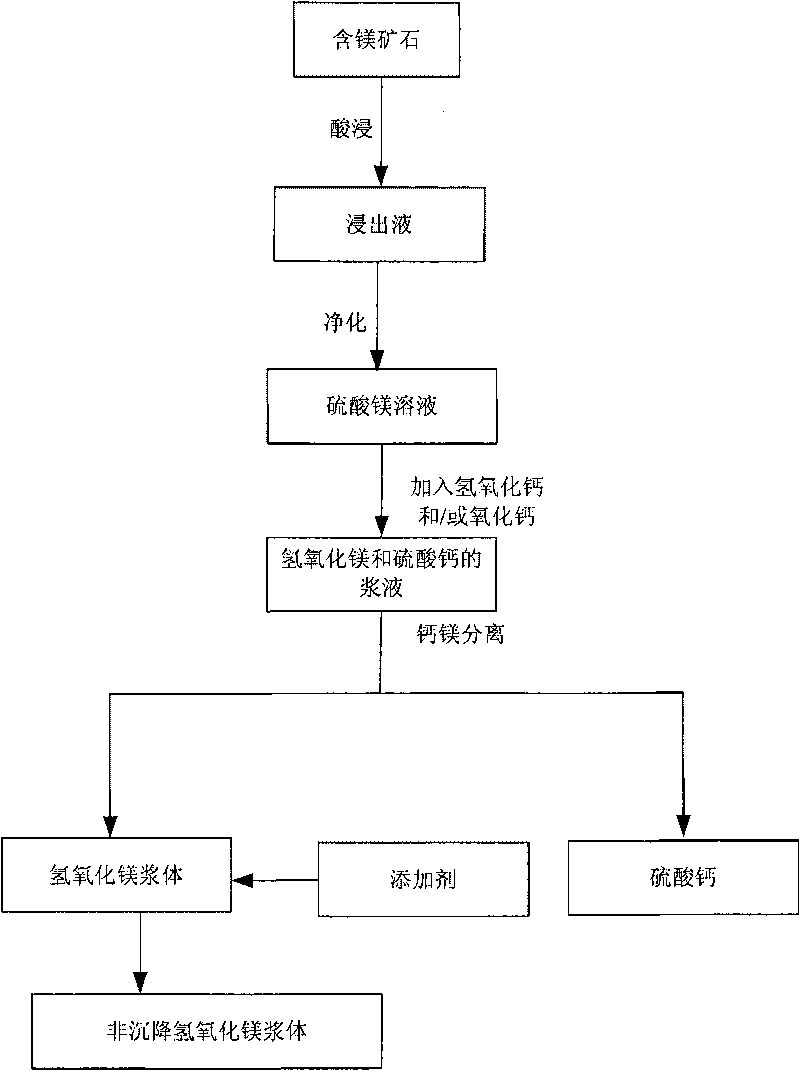

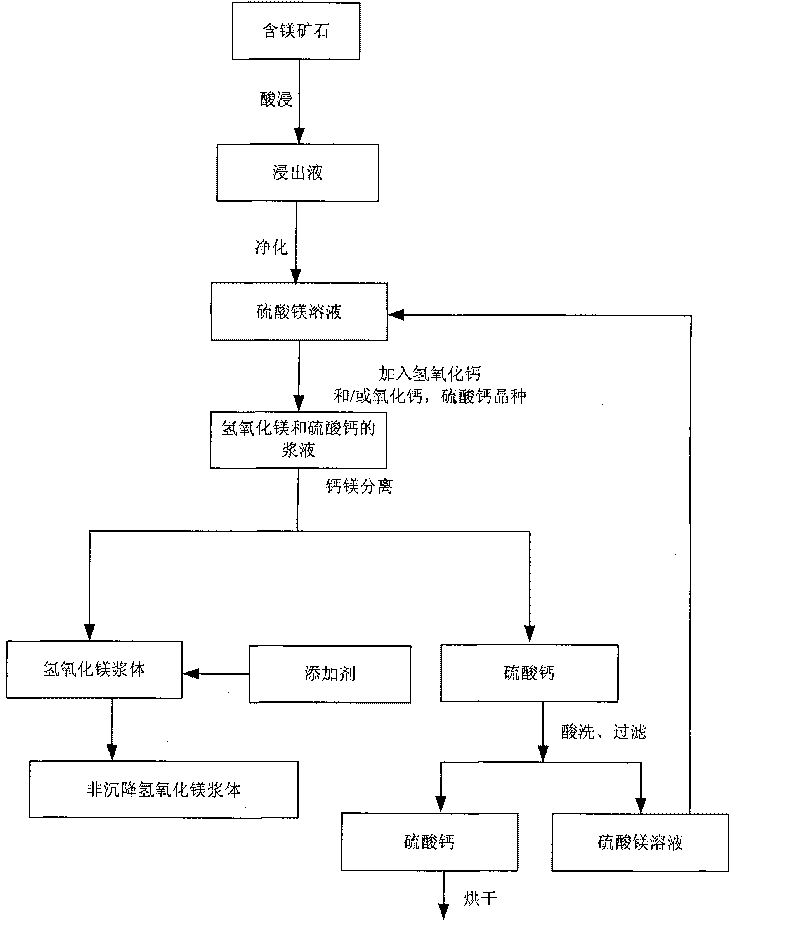

Method used

Image

Examples

example 1

[0049] Table 1: Composition table of magnesium sulfate solution obtained after sulfuric acid leaching solution of magnesium-containing ore is purified (g / l)

[0050] Mg

SO 4 2-

Al

Ni

co

mn

Fe

26

103

0.023

0.004

0.0016

0.0024

0.002

[0051] Get the magnesium sulfate solution 500ml of table 1

[0052] The magnesium sulfate solution is mixed with lime milk slurry with a concentration of 5% to 20 (weight percent), and the excess of lime milk is 1.05%

[0053] Precipitation time: 1 hour to 2 hours

[0054] Temperature: 35℃~55℃

[0055] Separation of gypsum and magnesium hydroxide

[0056] Output gypsum purity ≥ 95%, Mg ≤ 0.5-1%

[0057] Add additives to the magnesium hydroxide slurry and stir evenly

[0058] Stirring time: 0.5 hours to 1 hour

[0059] The magnesium hydroxide slurry is flocculated into a 20-45% non-settling magnesium hydroxide slurry.

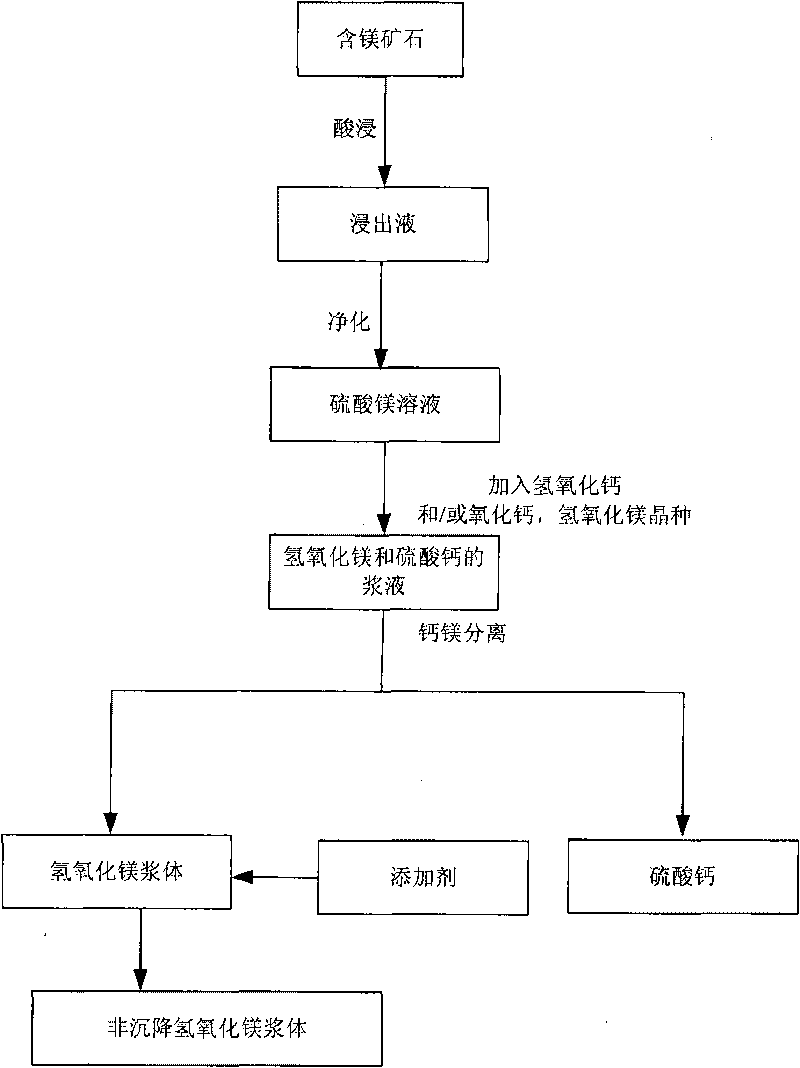

example 2

[0061] Add the pre-prepared gypsum seeds while mixing the milk of lime with the magnesium sulfate solution;

[0062] Other steps are the same as Example 1.

example 3

[0064] Add pre-prepared magnesium hydroxide seeds while mixing milk of lime with magnesium sulfate solution;

[0065] Other steps are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com