Unsupported alternating curved tube dry type evaporator

A dry evaporator and variable surface technology, applied in evaporators/condensers, tubular elements, heat exchange equipment, etc., can solve the problems of large flow resistance in the tube, reduced heat exchange efficiency, and large boundary layer thermal resistance. The effect of uniform flow distribution and flow velocity, increased effective heat transfer area, and reduced shell side pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the specific embodiments do not limit the protection scope of the present invention.

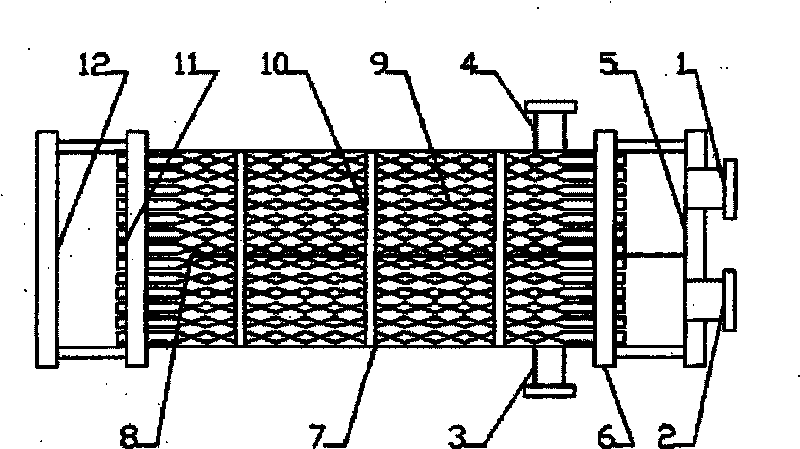

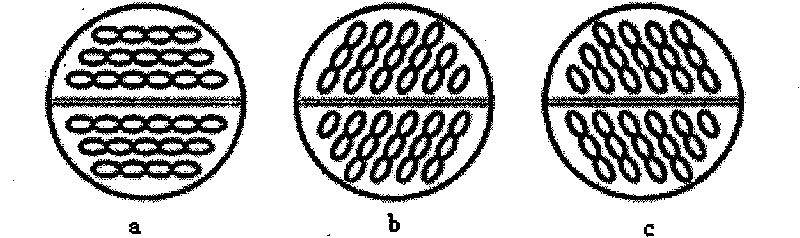

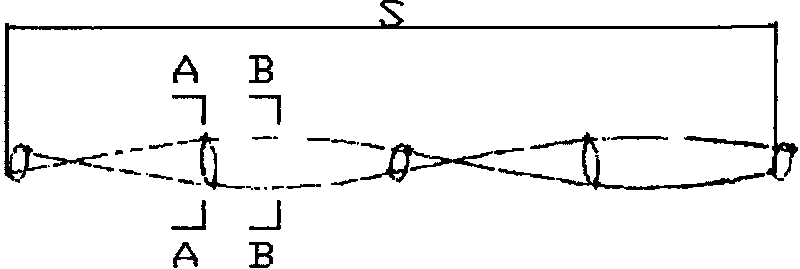

[0021] refer to figure 1 , an unsupported alternating surface tube dry-type evaporator includes a refrigerant inlet 1, a refrigerant outlet 2, a chilled water inlet 3, a chilled water outlet 4, a first head 5, a second head 12, a first tube sheet 6, The second tube sheet 11, the shell 7, the partition plate 8, the heat exchange tube 9 and the binding steel strip 10; The plate 6 and the second tube sheet 11, the first tube sheet 6 and the second tube sheet 11 are respectively connected with the first head 5 and the second head 12 to form a cavity; the refrigerant inlet 1 and the refrigerant outlet 2 are both arranged at the first On the head 5, it is separated by a partition 8. Such as image 3 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com