Antibacterial solidifying agent of excavated bamboo and wood ware

A solidifying agent, bamboo and wood technology, applied in the direction of wood processing equipment, wood impregnation, impregnated wood, etc., can solve the problems of environmental pollution, poor durability, affecting the texture of ancient wood, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

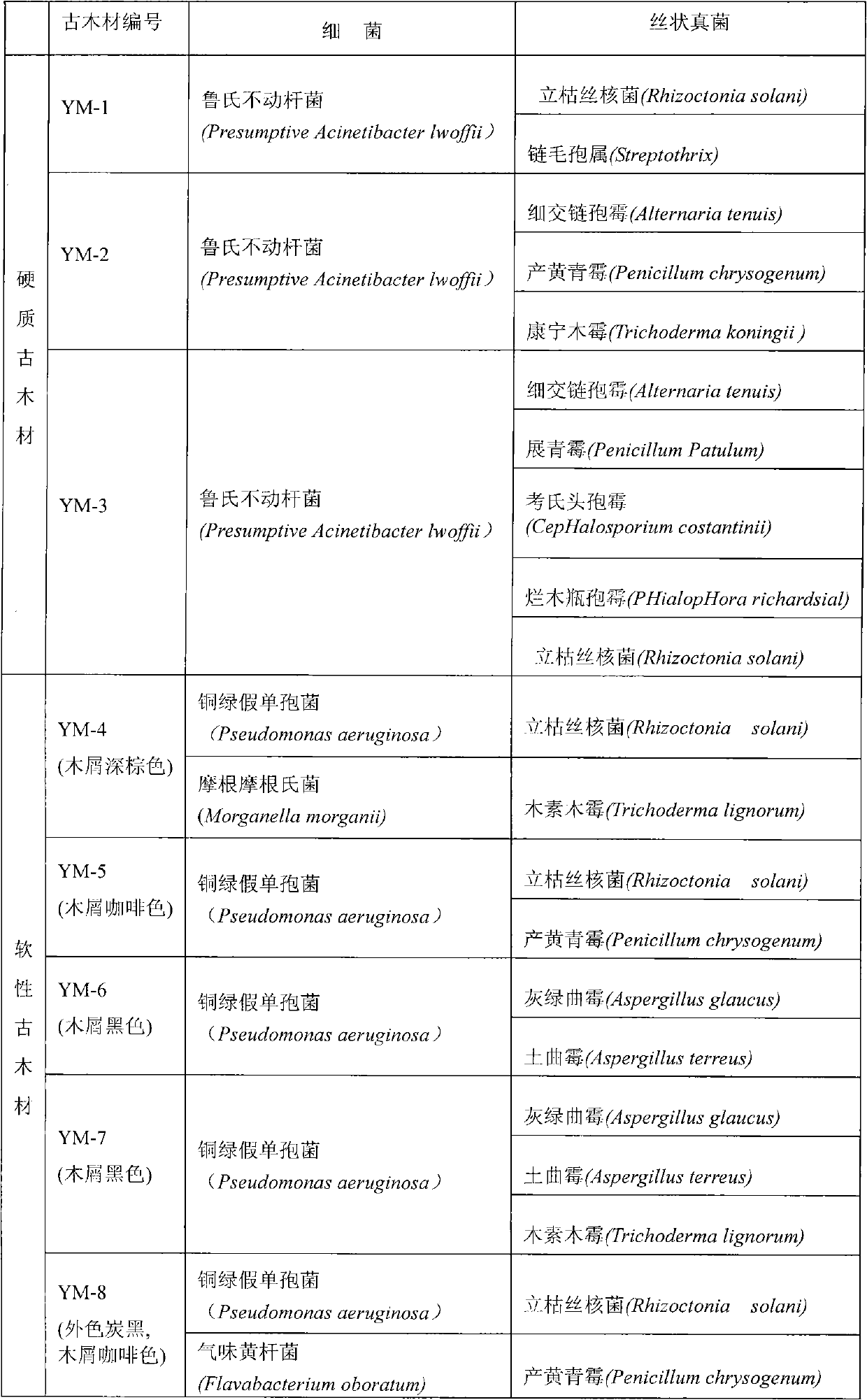

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In this scheme, the antibacterial solid agent contains the following components by weight:

[0061] Chitooligosaccharide 50 parts, catechin 100 parts, polyethylene glycol 1000 parts, water 850 parts, ethanol 150 parts.

[0062] Wherein the molecular weight of polyethylene glycol in the polyethylene glycol solution is 2000, the average molecular weight of chitosan oligosaccharide is 2000, the deacetylation degree is 94.2%, the epigallocatechin gallate EGCG content of catechin is 63.2%, The ECG content of epicatechin gallate is 14.6%, and the EC content of epicatechin is 8.5%.

[0063] Dissolve polyethylene glycol in water and ethanol to form a solution with a mass fraction of 20%; add chitosan and catechin to the above solution, and stir evenly at 40°C to 50°C; adjust the pH value to 5.5; 50 ℃~70℃ in a constant temperature bath, so that the polyethylene glycol solution is concentrated until the mass fraction of polyethylene glycol is 50%.

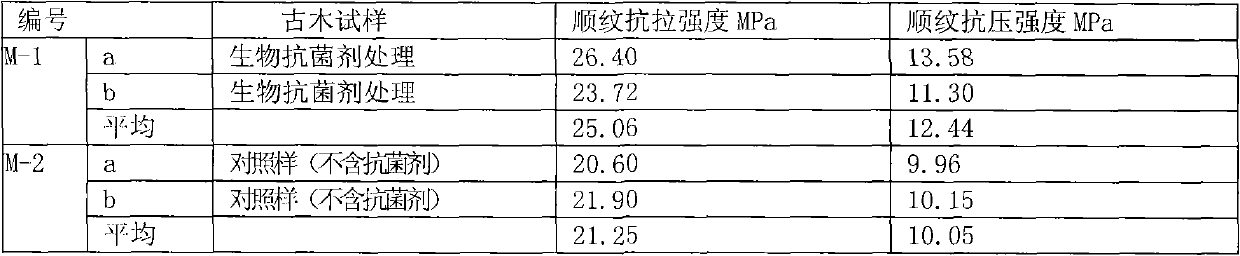

[0064] The mechanical proper...

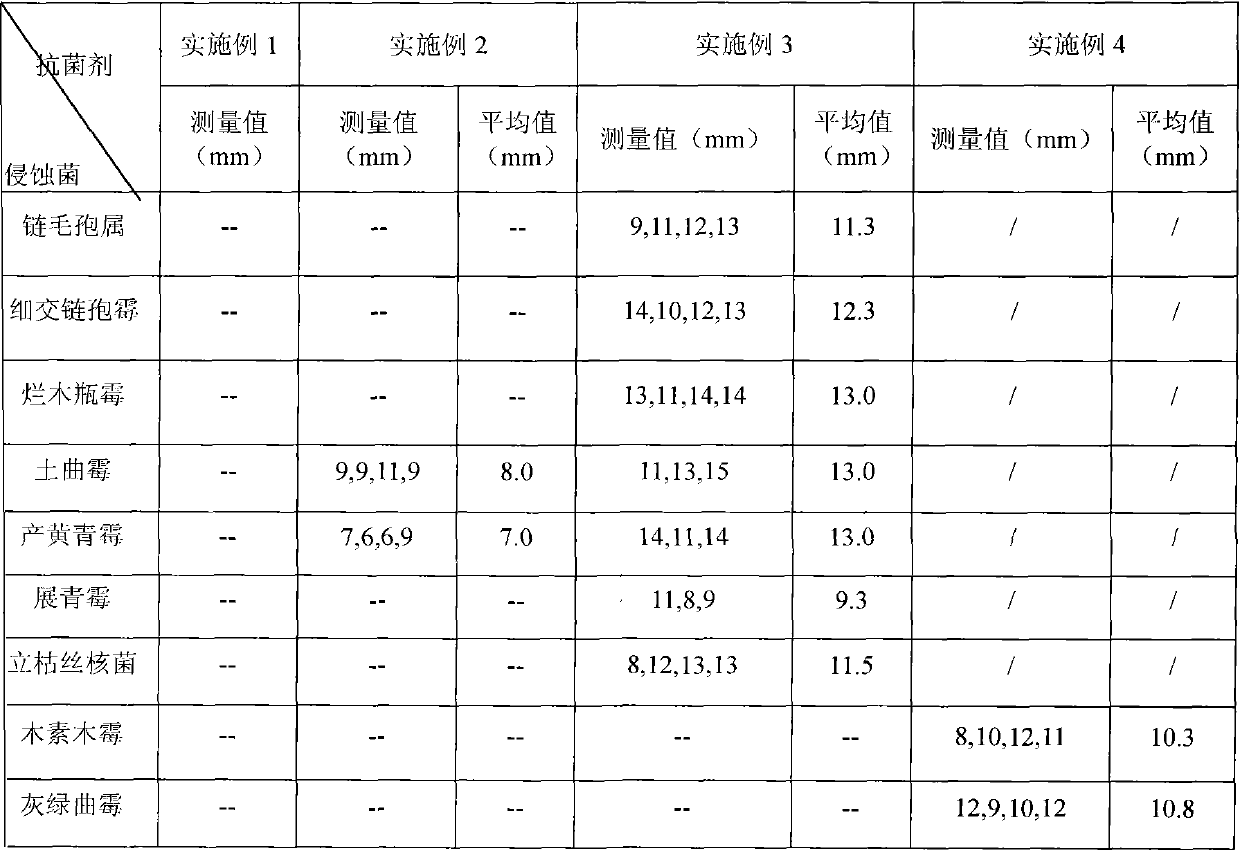

Embodiment 2

[0066] In this scheme, the antibacterial solid agent contains the following components by weight:

[0067] Chitooligosaccharide 4 parts, catechin 20 parts, polyethylene glycol 1000 parts, water 850 parts, ethanol 150 parts.

[0068] Wherein the molecular weight of polyethylene glycol in the polyethylene glycol solution is 1500, the average molecular weight of chitosan oligosaccharide is 1800, the deacetylation degree is 91%, the epigallocatechin gallate EGCG content of catechin is 60%, The ECG content of epicatechin gallate is 12%, and the EC content of epicatechin is 6%.

[0069] Dissolve polyethylene glycol in water and ethanol to form a solution with a mass fraction of 20%; add chitosan and catechin to the above solution, and stir evenly at 40°C to 50°C; adjust the pH value to 5.5; 50 ℃~70℃ in a constant temperature bath, so that the polyethylene glycol solution is concentrated until the mass fraction of polyethylene glycol is 30%.

[0070] This program is more suitable f...

Embodiment 3

[0072] In this scheme, the antibacterial solid agent contains the following components by weight:

[0073] Chitooligosaccharide 30 parts, catechin 40 parts, polyethylene glycol 1000 parts, water 850 parts, ethanol 150 parts.

[0074] Wherein the molecular weight of polyethylene glycol in the polyethylene glycol solution is 4000, the average molecular weight of chitosan oligosaccharide is 2200, the deacetylation degree is 96%, the epigallocatechin gallate EGCG content of catechin is 65%, The ECG content of epicatechin gallate is 16%, and the EC content of epicatechin is 10%.

[0075] Dissolve polyethylene glycol in water and ethanol to form a solution with a mass fraction of 20%; add chitosan and catechin to the above solution, and stir evenly at 40°C to 50°C; adjust the pH value to 5.5; 50 ℃~70℃ in a constant temperature bath, so that the polyethylene glycol solution is concentrated until the mass fraction of polyethylene glycol is 65%.

[0076] This scheme is more suitable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com