Fuel washing device for aircraft refueling vehicle

A technology of aircraft refueling and washing equipment, which is applied in the direction of fuel tank safety measures, etc., which can solve the problems of unfavorable flight of aircraft, increase of equipment size and weight, and limited time, and achieve the effect of even distribution of washing gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

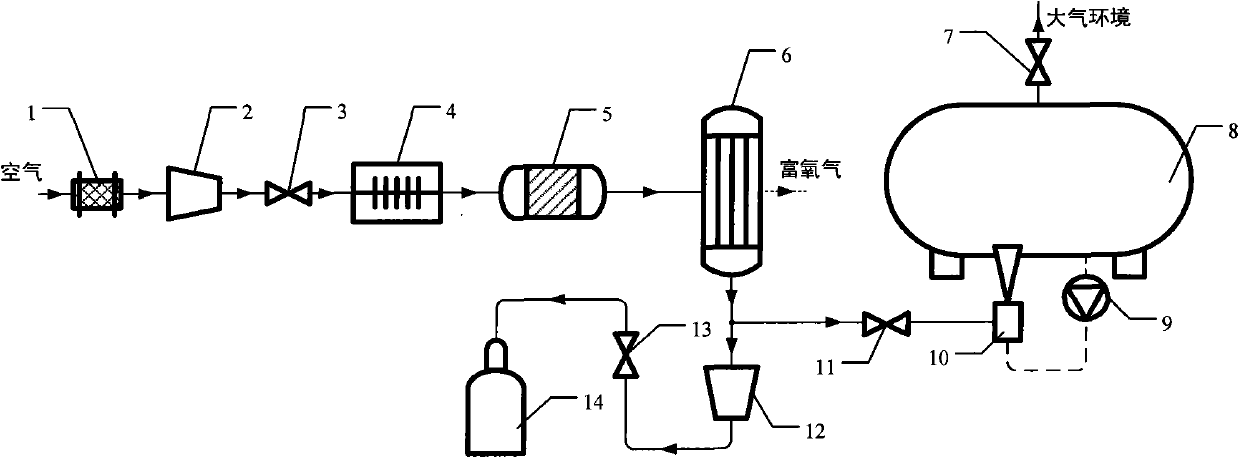

[0034] Such as figure 1 , image 3 and Figure 4 As shown, the aircraft refueling vehicle fuel washing device of the present invention includes a nitrogen-enriched gas generating device, a fuel circulation pump 9, a gas-oil mixing device and a refueling vehicle oil tank 8, wherein:

[0035]The gas-oil mixing device is respectively provided with an air inlet, an oil inlet hole and an output hole, and the gas-oil mixing device is composed of more than one washing nozzle 10, and the output hole of each washing nozzle 10, that is, the installation position of the nozzle opening is low. The lowest fuel level in the oil tank 8 of the refueling truck is used to ensure the safety and reliability of fuel washing in the fuel tank 8 of the refueling truck;

[0036] The nitrogen-enriched gas generating device comprises an air compressor 2, a nitrogen-enriched gas generator 6 and a heat exchanger 4 connected between the air outlet of the air compressor 2 and the air inlet 23 of the nitro...

Embodiment 2

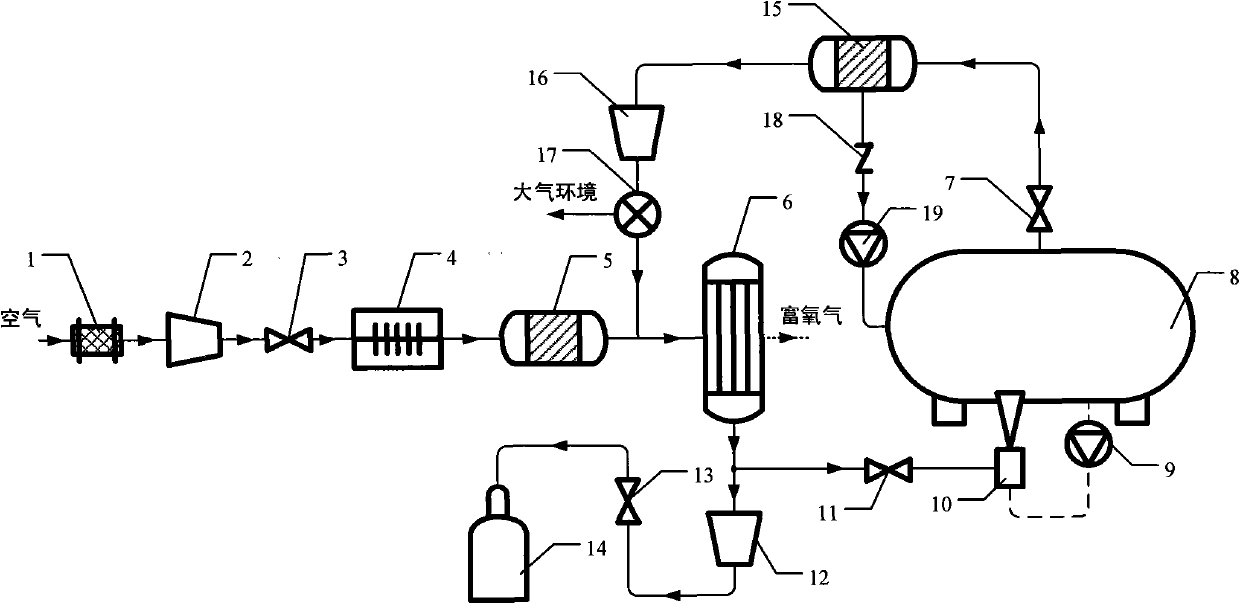

[0043] This embodiment is basically the same as Embodiment 1, the difference being that the outlet of the scrubbing exhaust valve 7 is connected to the exhaust gas recovery device through a gas delivery pipe, and the exhaust gas recovery device includes a scrubbing exhaust gas treatment unit 15, a scrubbing exhaust gas compressor 16 and fuel oil Recovery pump 19, the exhaust gas treatment unit 15 is a gas-oil separation device, the exhaust gas treatment unit 15 is provided with an oil outlet and an air outlet respectively, and the exhaust gas outlet of the exhaust gas treatment unit 15 passes through the oil delivery pipe and the fuel recovery pump 19 is connected to the liquid inlet hole, while the oil outlet hole of the fuel recovery pump 19 is connected to the oil tank 8 of the refueling vehicle, and a check valve 18 is connected to the oil delivery pipe between the exhaust gas treatment unit 15 and the fuel recovery pump 19. The air outlet of the unit 15 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com