Use of bisphosphine ligand in hydroformylation of olefin

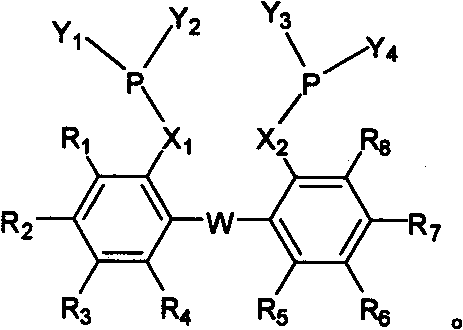

A bisphosphine ligand and hydroformyl technology, which is applied in the preparation of carbon monoxide reaction, organic compound/hydride/coordination complex catalyst, organic chemistry, etc., can solve the problems of less research and achieve high reaction conversion rate and selectivity sex excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

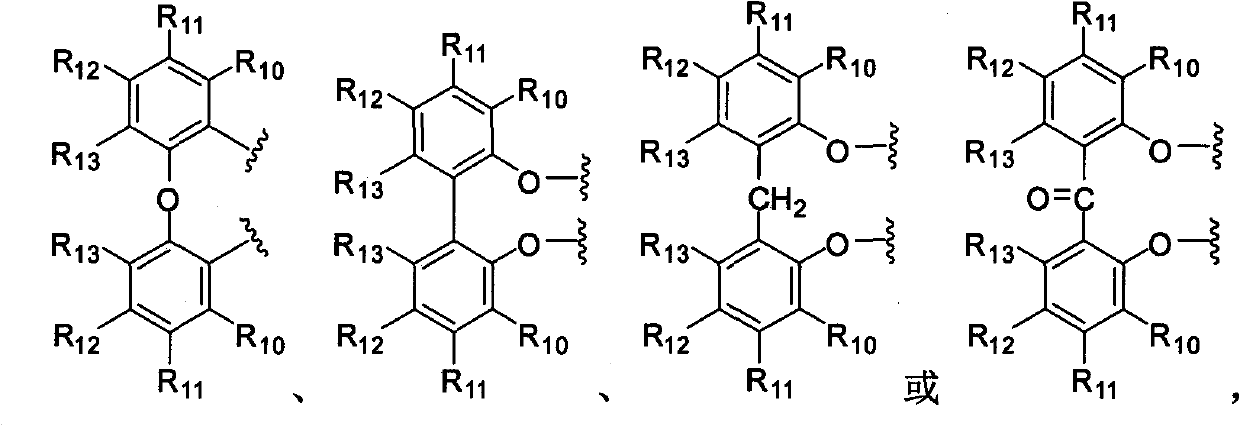

Method used

Image

Examples

Embodiment 1

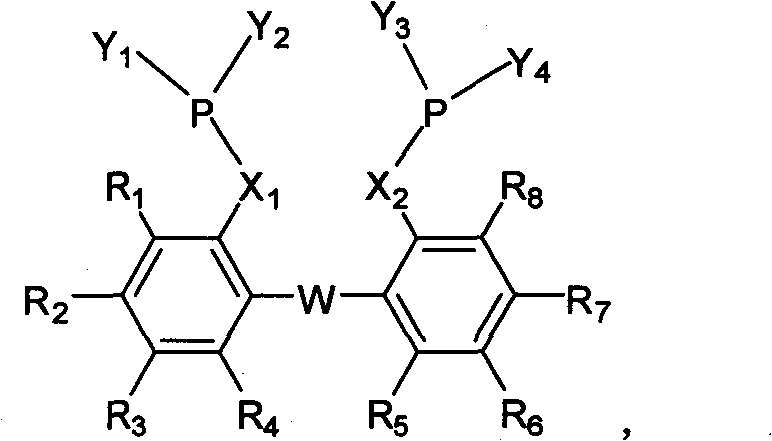

[0031] Example 1: Synthesis of the following bidentate phosphoramidite ligands

[0032]

[0033] Dipyrrole phosphorus chloride Synthesis from phosphorus trichloride and pyrrole: add anhydrous tetrahydrofuran (200mL) and phosphorus trichloride (8.7mL, 0.1mol) to a 500mL three-neck flask under argon atmosphere, add pyrrole (13.9mL, 0.2 mol) and triethylamine (28mL, 0.2mol) in anhydrous tetrahydrofuran (50mL) solution, after 2 hours of dropwise addition, slowly warm up to room temperature and stir overnight, remove triethylamine hydrochloride by filtration under argon atmosphere, reduce pressure Most of the solvent was evaporated, and the residue was purified by distillation under reduced pressure. Fractions at 80° C. (1 mmHg) were collected to obtain 16.0 g of a colorless oil, with a yield of 81%. 1 H NMR (300MHz, CDCl 3 )δ7.07-7.10 (m, 4H), 6.39 (t, J = 2.1Hz, 4H); 31 P NMR (121.46MHz, CDCl 3 )δ104.35(s).

[0034] Under argon atmosphere, add dipyrrole phosphorus chlori...

Embodiment 2

[0036] Example 2: Synthesis of the following bidentate phosphoramidite ligands

[0037]

[0038] Under argon atmosphere, add dipyrrole phosphorus chloride (600mg, 3.0mmol) and anhydrous tetrahydrofuran (5mL) into a 50mL Schlenk tube respectively, cool to 0°C, drop (0.26g, 1.2mmol) and anhydrous triethylamine (0.46mL, 3.3mmol) in anhydrous tetrahydrofuran (5mL) solution, slowly warming up to room temperature and stirring overnight, stop the reaction, spin off the solvent under reduced pressure, column chromatography ( Eluent: petroleum ether: CHCl 3 =1 / 1) 239 mg of a colorless oily substance was isolated, with a yield of 37%.

[0039] 1 H NMR (400MHz, CDCl 3 )δ=7.61(d, J=7.2Hz, 2H), 7.37(t, J=7.5Hz, 2H), 7.17(t, J=7.2Hz, 2H), 6.91(s, 8H), 6.77(d, J=7.8Hz, 2H), 6.34(d, J=1.5Hz, 8H); 31 P NMR (121.46MHz, CDCl 3 ,) δ=107.14(s); 13 C NMR (75MHz, CDCl 3 )δ=151.37, 151.22, 133.33, 131.47, 131.05, 124.26, 121.47, 121.36, 121.24, 119.14, 118.95, 112.78, 112.43, 112.36; , 1...

Embodiment 3

[0040] Example 3: Synthesis of the following bidentate phosphoramidite ligands

[0041]

[0042] Under argon atmosphere, add dipyrrole phosphorus chloride (600mg, 3.0mmol) and anhydrous tetrahydrofuran (5mL) into a 50mL Schlenk tube respectively, cool to 0°C, drop (0.656g, 1.2mmol) and anhydrous triethylamine (0.46mL, 3.3mmol) in anhydrous tetrahydrofuran (5mL) solution, slowly warming up to room temperature and stirring overnight, stop the reaction, spin off the solvent under reduced pressure, column chromatography ( Eluent: petroleum ether: CHCl 3 =1 / 1) isolated to obtain 826mg of yellow solid with a yield of 79%.

[0043] m.p.60-61℃; 1 H NMR (400MHz, CDCl 3 )δ=7.27-7.17(m, 14H), 7.03-7.00(m, 10H), 6.82-6.79(m, 8H), 6.55(dd, J=1.6, 6.8Hz, 2H), 6.24(dd, J= 2.0, 2.4Hz, 8H), 5.41(s, 2H); 31 P NMR (121.46MHz, CDCl 3 ,) δ=106.26(s); 13 C NMR (75MHz, CDCl 3 )δ=192.99,149.87,149.77,142.97,140.01,134.16,132.05,131.02,130.98,129.26,128.43,128.34,126.57,126.42,121.56,121.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com