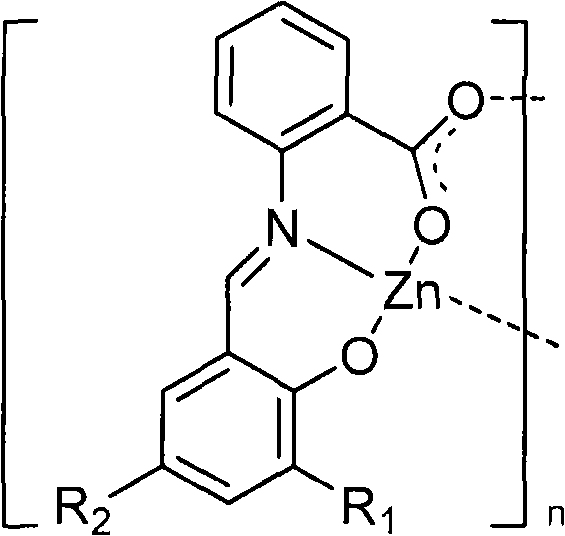

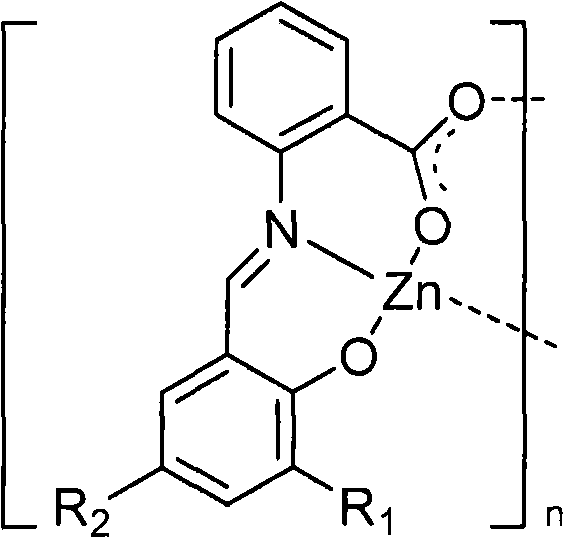

Application of aromatic zinc carboxylate complex catalyst for preparing aliphatic polycarbonate

A technology of zinc aromatic carboxylate and polycarbonate, which is applied in the application field of zinc aromatic carboxylate complex catalysts for the preparation of aliphatic polycarbonate, can solve the problem of low carbon dioxide reactivity, achieve stable structure, and prepare The effect of simple method and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put 0.10g of salicylaldehyde condensation anthranilate zinc complex catalyst and a stirrer into a pre-dried 100mL stainless steel autoclave, heat up to 120°C and vacuum dry for 6h, cool to room temperature, fill with carbon dioxide to normal pressure, Add 20 mL (19.2 g) of epoxycyclohexane into the reaction kettle with a glass syringe, fill with carbon dioxide, keep the pressure at 4.5 MPa, stir the reaction at 110° C. for 80 h, stop the reaction, and cool to room temperature.

[0019] Take out the reactant, recover the unreacted epoxycyclohexane by distillation under reduced pressure, dissolve the residue with an appropriate amount of dichloromethane, slowly add it dropwise to a sufficient amount of methanol stirred at high speed, and precipitate a high polymer, filter, methanol Washing and vacuum drying yielded 15.9 g of aliphatic polycarbonate. Its average molecular weight measured by gel permeation chromatography is 53600, through 1 H NMR analysis showed that the a...

Embodiment 2

[0021] In the same equipment used in Example 1, under the same conditions, the addition of epoxycyclohexane was 10mL (9.6g), at 70°C, the pressure was kept at 3.0MPa, and the reaction was carried out for 60h to obtain aliphatic polycarbonate 2.2 g of the ester, its average molecular weight is 32500, the alternating copolymerization rate of carbon dioxide and epoxycyclohexane is 95.2%, and the catalytic efficiency is 103 g of polymer / g of zinc.

Embodiment 3

[0023] In the same equipment used in Example 1, under the same conditions, the salicylaldehyde condensation anthranilate zinc complex catalyst is changed into 5-methyl salicylaldehyde condensation anthranilate zinc complex catalyst, and the ring The addition of oxycyclohexane was changed to 16ml (15.4g), and reacted at 4.0MPa and 110°C for 72h to obtain 18.2g of aliphatic polycarbonate, whose average molecular weight was 58400, and the alternating copolymerization ratio of carbon dioxide and epoxycyclohexane is 96.5%, and the catalytic efficiency is 893 g polymer / g zinc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com