Panicum miliaceum yellow wine production technology

A production process, millet technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of low alcohol yield, unobvious health function, and affecting the quality of wine, and achieve the effect of high alcohol yield, good quality, and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 Raw material proportioning is 50 kilograms of soft broomcorn millet, 8 percent wheat koji, 1 percent active dry yeast, and 75 kilograms of water.

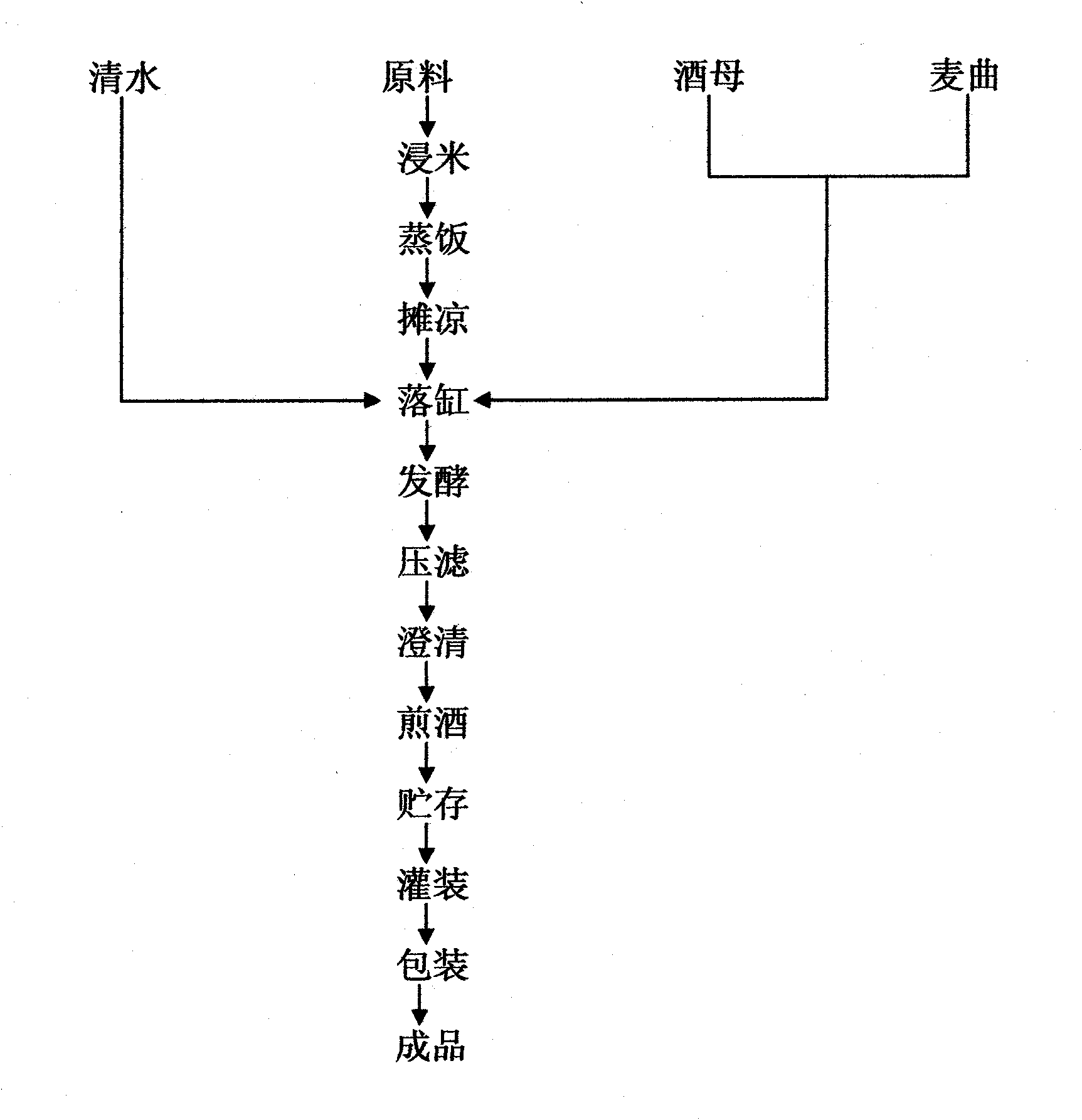

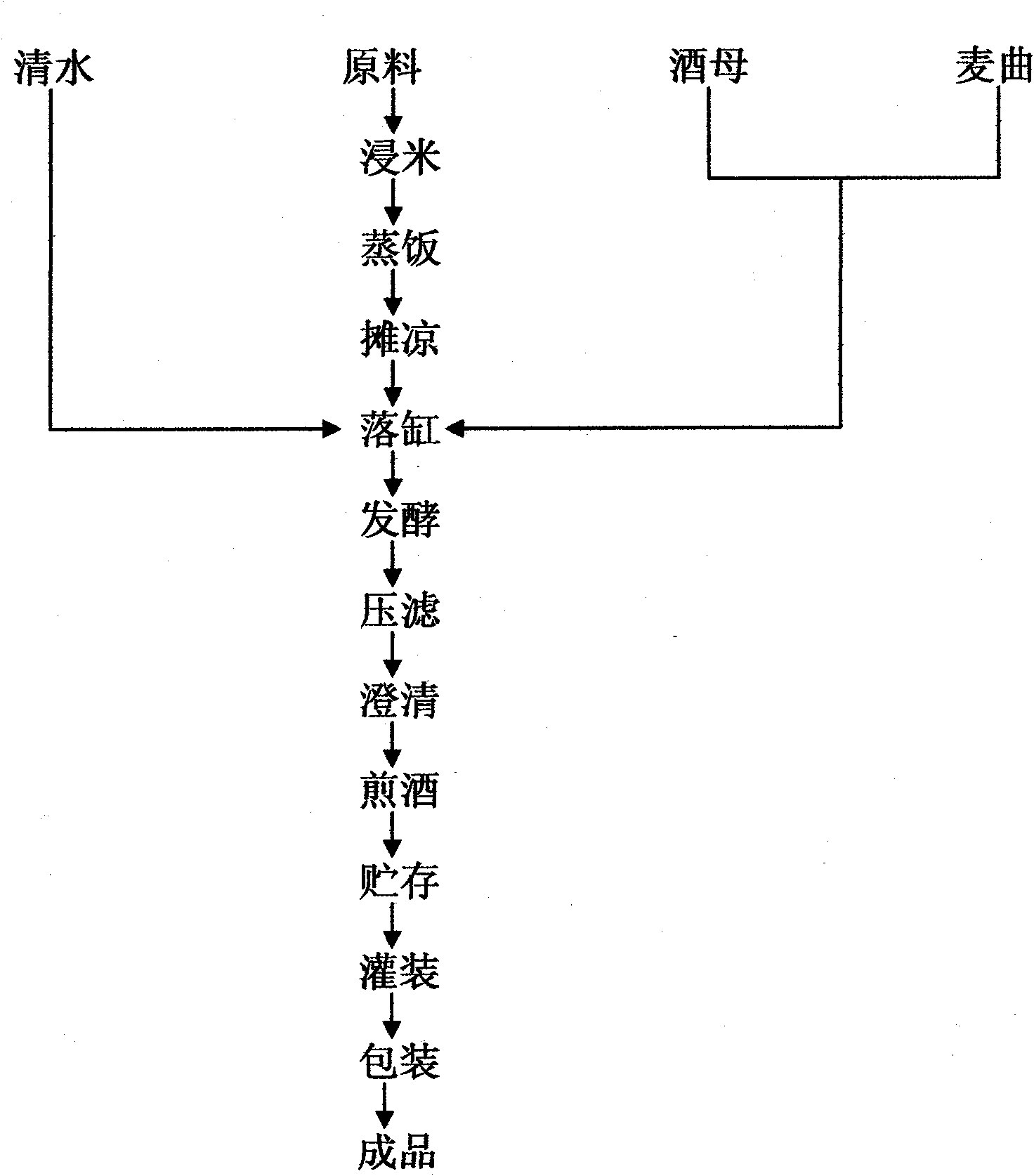

[0027] Process flow: according to the following process flow

[0028] The raw materials are soaked in rice, steamed, and cooled, and then put into the tank together with water, distiller's mother, and wheat koji, and then stored after fermentation, pressure filtration, clarification, and decoction, and then the stored wine is filled. , which is the finished product after packaging.

[0029] Requirements for raw materials and brewing water

[0030] (1) Requirements for soft millet: the fruit is ripe and plump, pure and free from impurities, moth-eaten and mildew. The physical and chemical indicators are as follows:

[0031] starch content

Moisture %

Impurities

leather shell

Milling rate

More than 60%

10-12

0.2% or less

0.2% or less

90%

[0032] (2) Requi...

Embodiment 2

[0100] Example 2 is basically the same as Example 1, except that the process parameters are different; its raw material ratio is that the ratio of broomcorn millet to water is 2: 3, and then add 7% wheat koji and 1% active dry yeast during fermentation . The time for soaking rice is 18h-20h because it is summer.

Embodiment 3

[0101] Example 3 is basically the same as Example 1, except that the process parameters are different; its raw material ratio is that the ratio of broomcorn millet to water is 2: 3 and then add 10% wheat koji and 1% active dry yeast during fermentation . The rice soaking time is selected from 20h to 25h in winter.

[0102] The parts not described in detail in the embodiments are based on known technologies or common sense in the industry. Suspected to damage the quality of the wine.

[0103] (2) Bottling: Bottling includes wine filling into bottles and capping operations. Rubber tubes are used for bottling and the siphon method is used, but the bottle caps can be used after being soaked in 75° alcohol for sterilization.

[0104] (3) Sterilization: After bottling, pasteurization is carried out. The temperature used was 65°C for half an hour. The method is: put the bottle containing wine into the sterilizing tank, immerse the bottle in water, turn on the air, put a thermomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com