High-efficiency mixer igniter used for pulse soot blower

A soot blower and mixing point technology, applied in the field of high-efficiency mixing igniters, can solve the problems of poor mixing uniformity of the mixer, and achieve the effect of improved mixing uniformity, high mixing uniformity, and exquisite design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

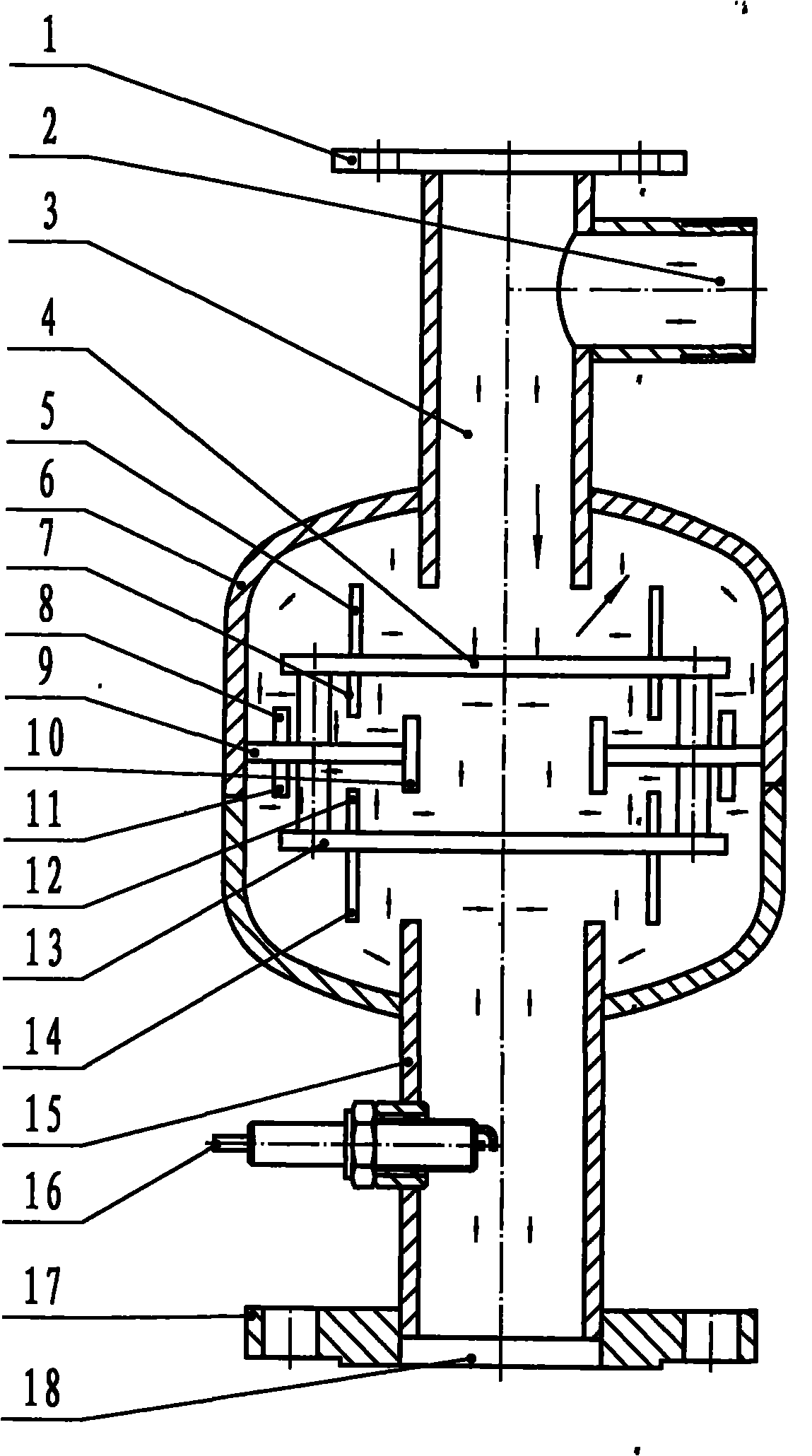

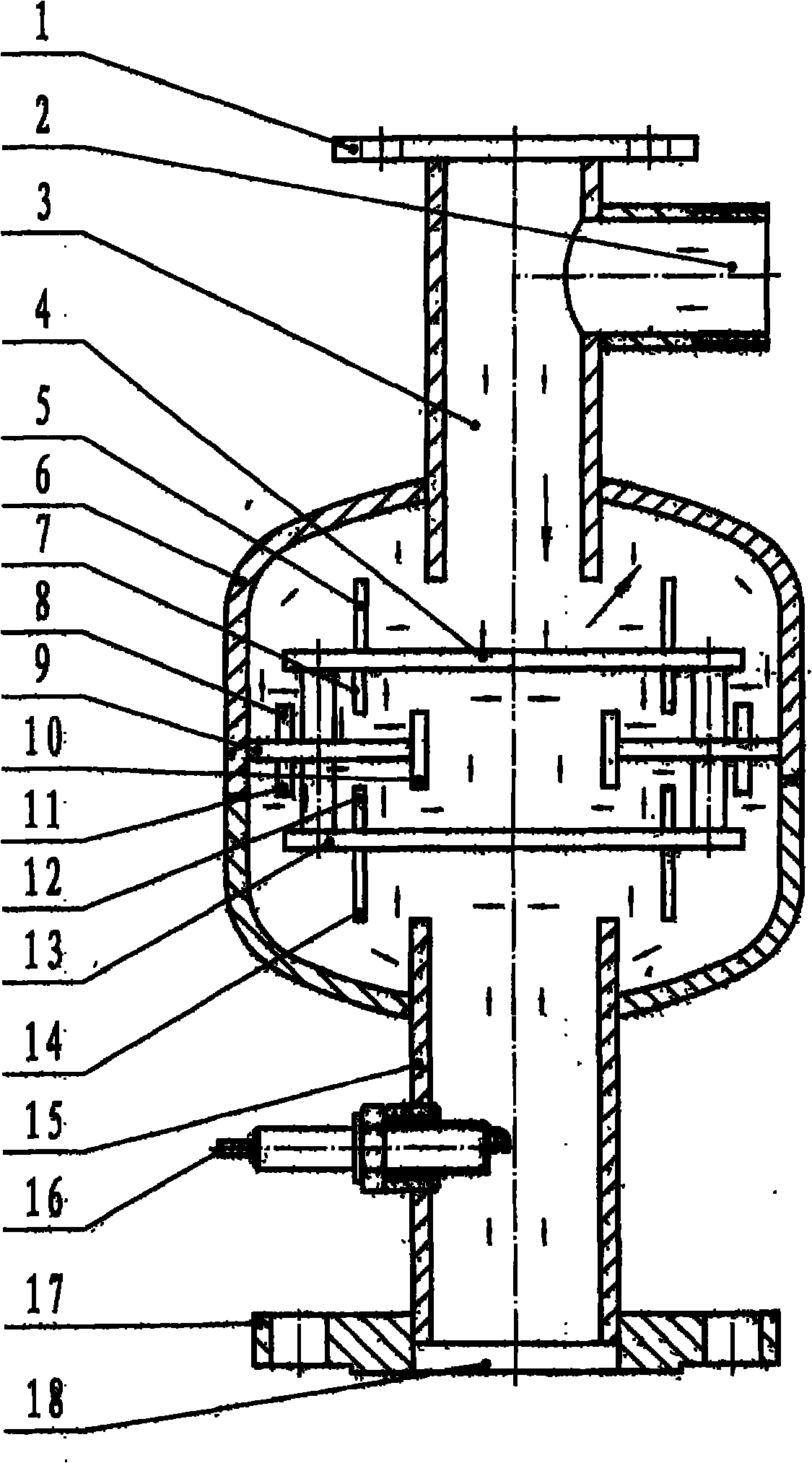

[0014] Fuel gas and air are in the state of laminar flow, first hit the upper splitter baffle (4) through the air inlet (2), the gas disperses around and hits the inlet upper retaining ring (5), and hits the upper casing (6) upwards , hits the collector baffle (9) downward, flows inward and hits the inlet lower retaining ring (7), then hits the collector baffle (9) downward, flows inward and hits the gas collector (10), and hits again The upper diverter baffle (4), when the gas flows towards the center, the gas collides with each other; when it hits the lower diverter baffle (12) downward, the gas disperses and hits the upper retaining ring of the outlet (11), and the gas hits the collector upwards Baffle (9), the gas hits the collector baffle (4) upwards, and hits the shell (3) outwards, the gas hits the outer diameter of the upper end of the outlet pipe (15) along the shell, and the gas hits the upper end of the outlet pipe (15) upwards When the lower diverter baffle reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com