Zero drift compensation method of Hall magnetic sensor

A zero-point drift, magnetic sensor technology, applied in instruments, electric solid-state devices, semiconductor devices, etc., can solve the problems of poor ohmic contact of electrodes, not easy to miniaturize magnetic sensors, intelligent development, uneven temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

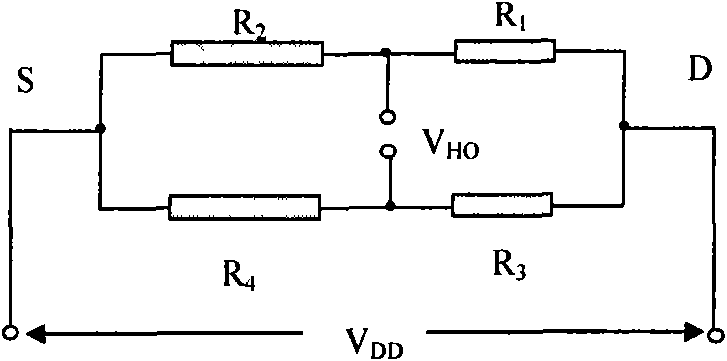

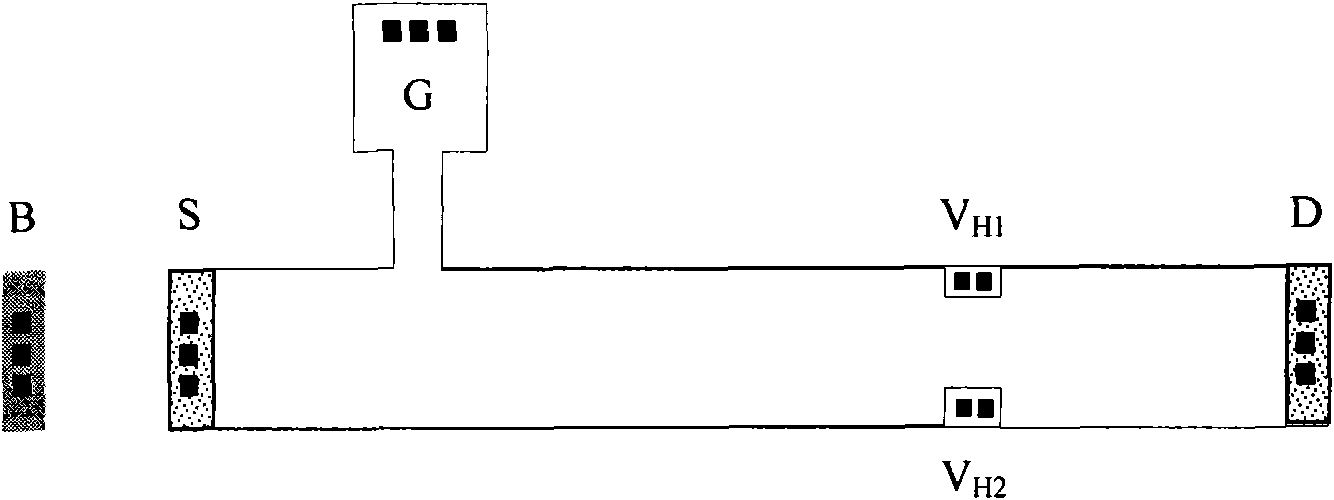

[0028] The method of compensating for the zero drift of the Hall magnetic sensor is to make the MOSFET Hall Hall magnetic sensor through the CMOS process. The four equivalent resistance resistances of the channel of the Hall magnetic sensor change with the external gate voltage.

[0029] The CMOS process includes flushing, first oxidation, first photolithography, second oxidation, P-type doping, third oxidation, and 215 photolithography.

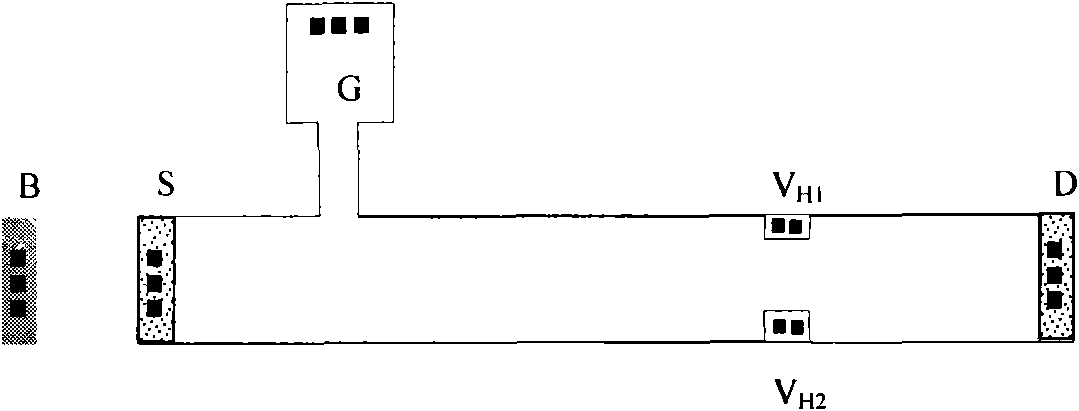

[0030] See attached figure 1 , N-type double-sided polished high-resistance (ρ>100Ω·cm) single crystal silicon wafer with a thickness of 450 μm, boiled with concentrated sulfuric acid until white smoke, rinsed with a large amount of deionized water after cooling, and then cleaned with cleaning solution DZ-1 , DZ-2 were washed twice each, rinsed with a large amount of deionized water, and dried in a dryer;

[0031] Put the cleaned monocrystalline silicon wafer into a high-temperature oxidation furnace for primary oxidation, and use a thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com