AlGaInP system LED with electron hole dual limitation and preparation method thereof

An electron-hole, dual technology, applied in the field of optoelectronics, can solve the problems of poor thermal characteristics, low optical power, low luminous efficiency, etc., and achieve the effects of low cost, high repeatability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

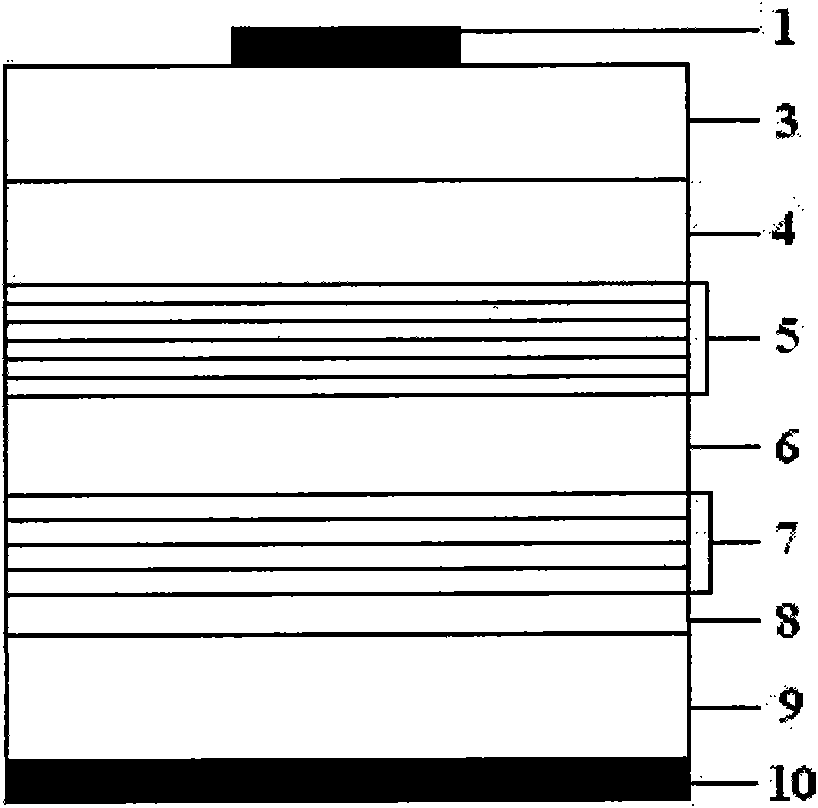

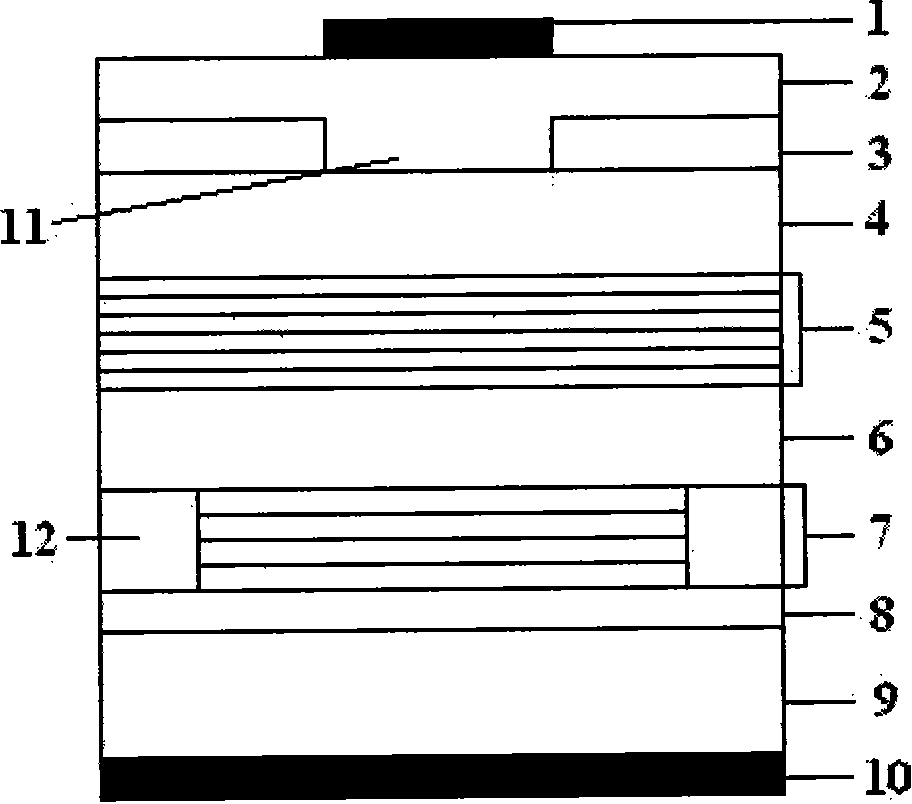

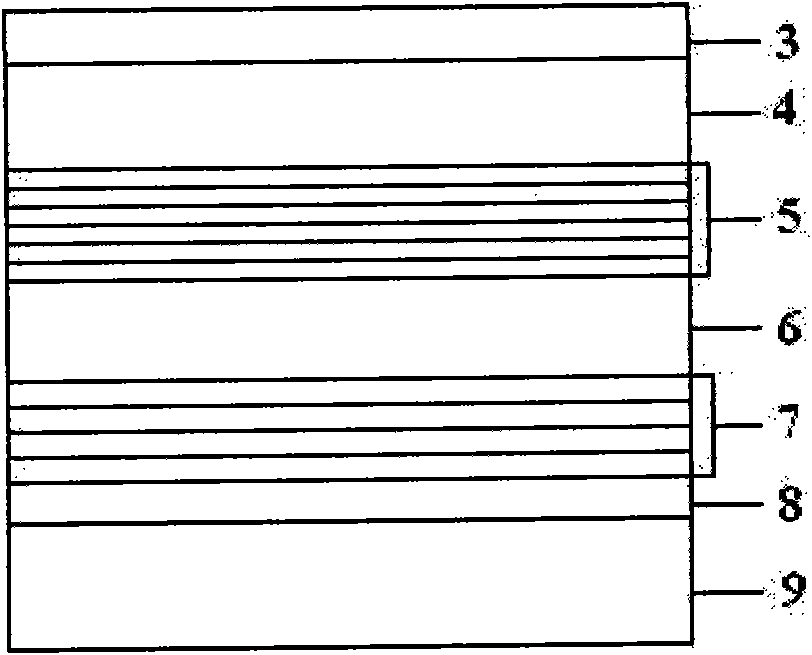

[0027] The AlGaInP LED with double restriction of electrons and holes of the present invention has a chip structure such as figure 2 As shown, from top to bottom, it includes an upper electrode 1, an ITO conductive light-transmitting layer 2, a GaP window layer 3, an upper confinement layer 4, an active region 5, a lower confinement layer 6, a Bragg reflective layer 7, a buffer layer 8, and a substrate 9 and lower electrode 10. The GaP window layer 3 is provided with an etching area corresponding to the shape and position of the upper electrode 1. The etching area is as deep as the upper surface of the upper confinement layer 4. The ITO conductive light-transmitting layer 2 extends from the etching area on the GaP window layer 3 to the upper surface. On the upper surface of the confinement layer 4, a Schottky contact is formed, and a current blocking region 11 is formed. The maximum carrier concentration of ITO conductive light-transmitting layer 2 reaches 10 21 cm -3 Order of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com