Processing method of high-protein lucerne refined leaf meal

A processing method and high-protein technology, applied in the processing field of high-protein alfalfa fine leaf powder, can solve problems such as poor quality and poor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

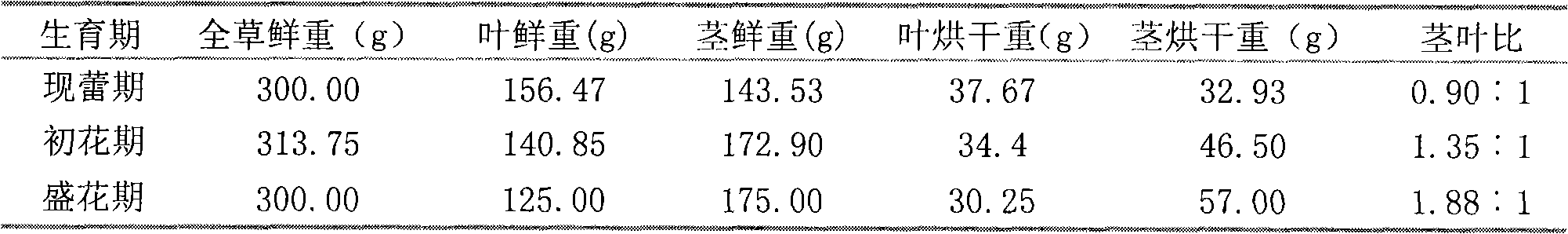

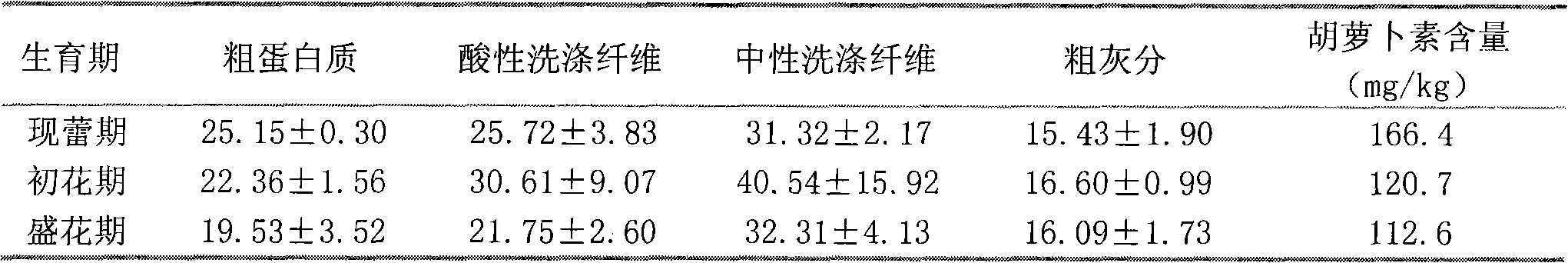

Method used

Image

Examples

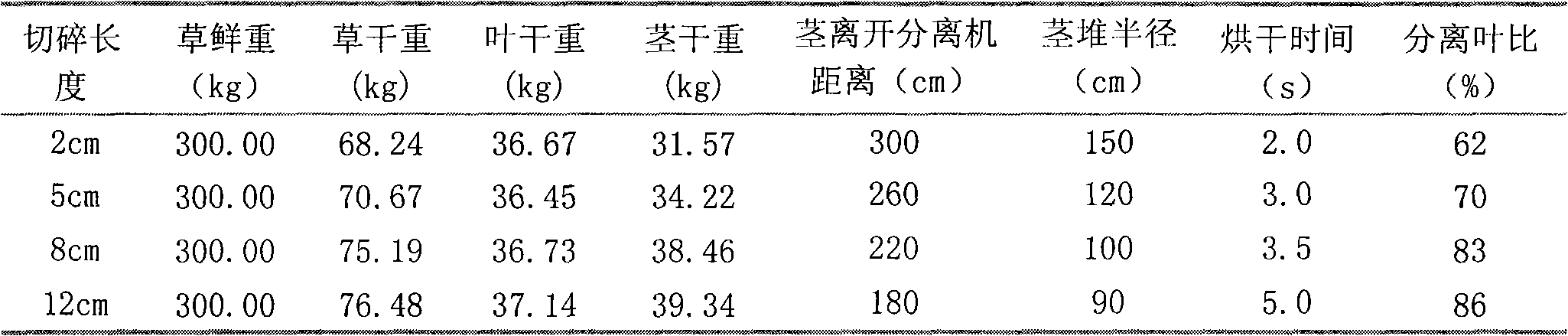

Embodiment 1

[0026] Embodiment 1, in the high-protein alfalfa fine leaf powder processing method of the present invention, at first alfalfa grass is cut into 8cm long segment, makes alfalfa stem long and heavy and is easy to dry the back stem and leaf separation; High temperature oven dry 3 seconds , the inlet temperature is 900-1100°C, the outlet temperature is 70-80°C, the moisture content of alfalfa stems is 16%, and the moisture content of leaves is 10%. Fall, so that the stem leaves are easy to separate; the hammer mill (this pulverizer is a conventional product on the market) of 500r / min is pulverized with the rotating speed without sieve. Heavy; the leaves are completely crushed, and the crushed body is lighter; at the same time, the leaves can be completely detached from the stem, and the separation rate and work efficiency of the leaves can also be improved; use a "positive airflow" type fan with a wind speed of 0.2m / s to crush The stems and leaves are separated, the heavier stems...

Embodiment 2

[0027] Embodiment 2, in the high-protein alfalfa fine leaf powder processing method of the present invention, at first the alfalfa grass is cut into 12cm long segments, so that the alfalfa stems are long and heavy and easy to dry and the stems and leaves are separated; high temperature drying for 3 seconds , the inlet temperature is 900-1100°C, the outlet temperature is 70-80°C, the moisture content of alfalfa stems is 17%, and the moisture content of leaves is 5%. It is easy to fall, so that the stems and leaves are easy to separate; use a hammer mill with a speed of 500r / min without a sieve to crush. Under this crushing condition, the stems are not completely crushed, and the crushed body is heavy; the leaves are completely crushed, and the crushed body Lighter; at the same time, the leaves can be completely detached from the stems, and the separation rate and work efficiency of the leaves can be improved; the crushed stems and leaves can be separated with a "positive pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com