Preparation method of activated carbon loaded and Zn2+/TiO2-doped photocatalyst

A photocatalyst, activated carbon technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., to achieve the effects of easy promotion, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

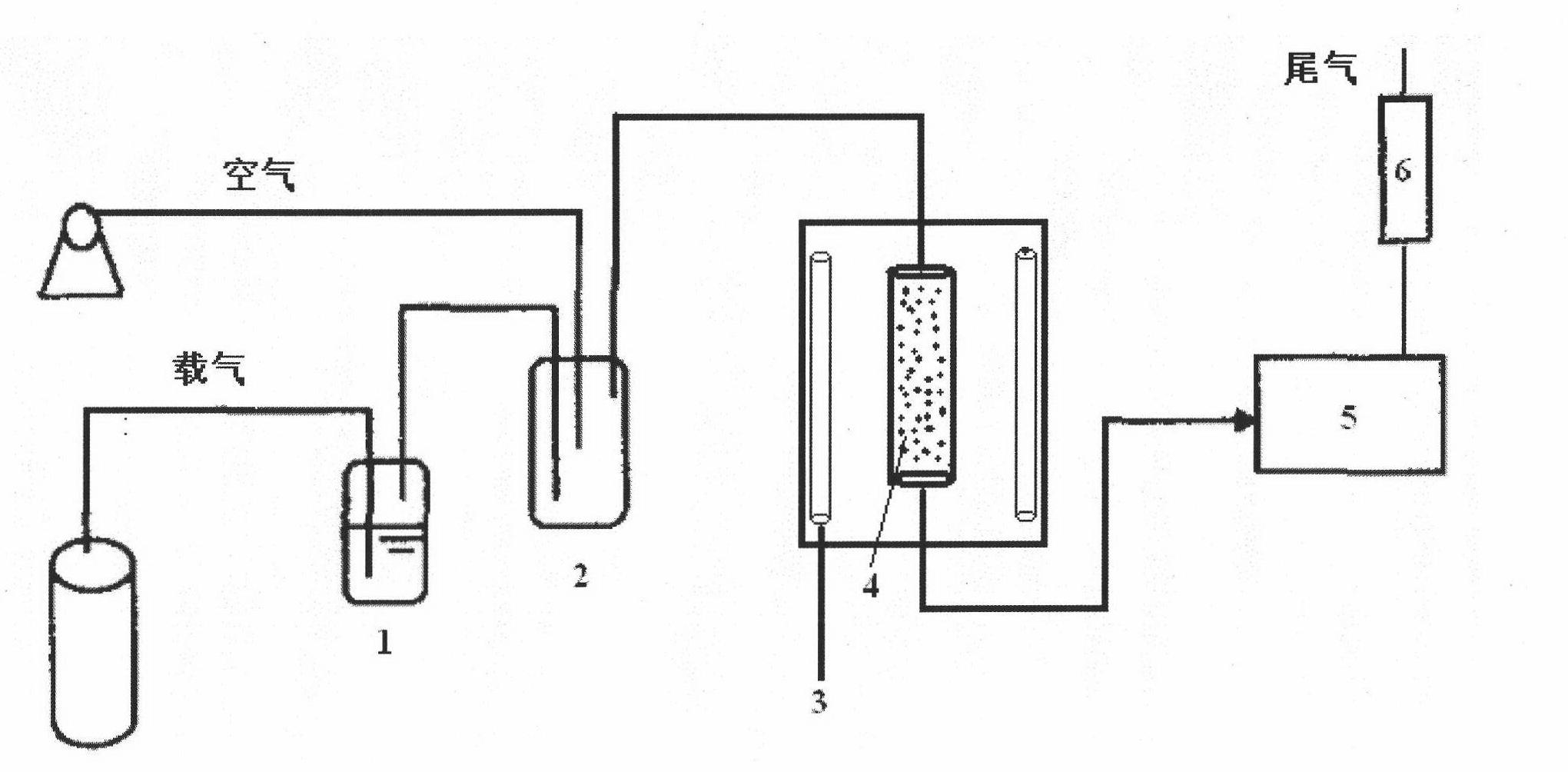

Method used

Image

Examples

preparation example Construction

[0020] A kind of activated carbon supported doped type Zn 2+ / TiO 2 The preparation method of photocatalyst comprises the following steps:

[0021] In the first step, 1-2.98g of zinc nitrate is weighed, and zinc nitrate, 1.5ml of distilled water and 2ml of glacial acetic acid are added to 15ml of absolute ethanol under stirring to form solution A.

[0022] Under vigorous stirring, add 8-15ml of tetrabutyl titanate into 30ml of absolute ethanol, and stir for 1-2h to fully hydrolyze to form solution B.

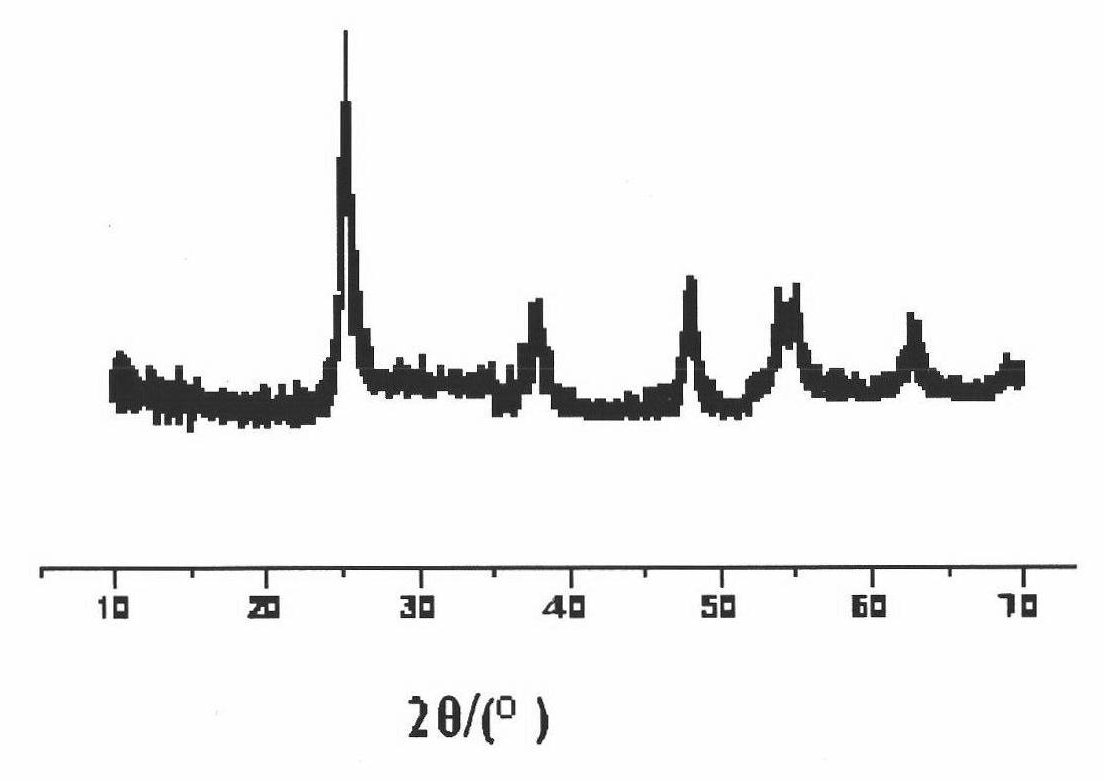

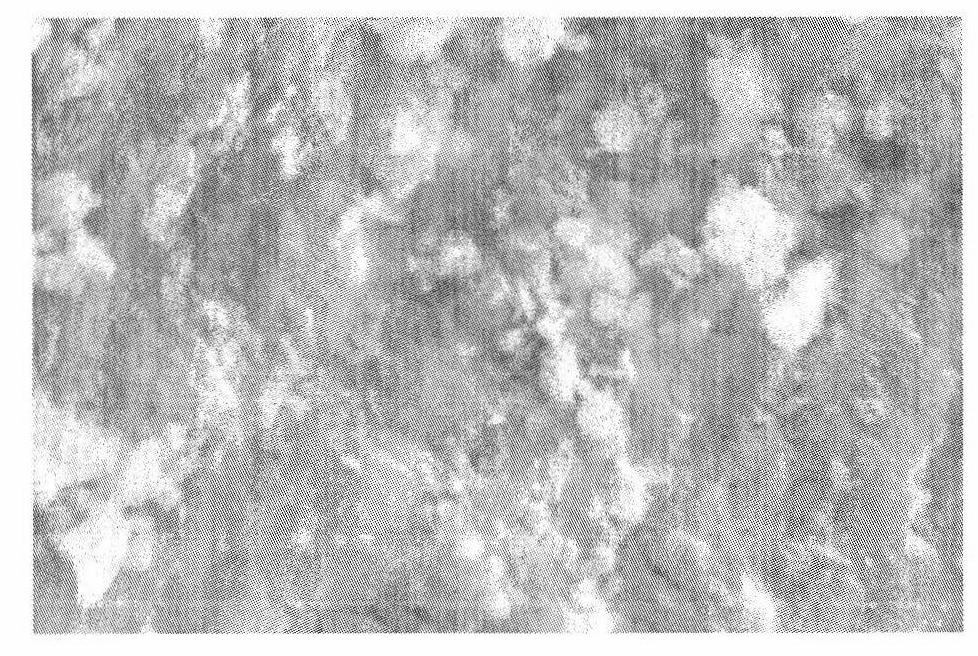

[0023] In the second step, after stirring well, slowly drop solution A into B, and continue stirring for 30 minutes to make the reaction fully. Then add 10-15g of activated carbon with a clean surface, stir vigorously for 1 hour to fully mix, soak for 12-72 hours, filter, wash with absolute ethanol and deionized water several times, after cleaning, place the loaded activated carbon at 120 Dry at ℃ for 2h, and then bake at 300-550℃ for 2h to obtain activated carbon supported d...

Embodiment 1

[0028] The bamboo is taken and crushed, cleaned and dried for later use. Phosphoric acid was used as an activator, and the mass ratio of activator to bamboo was 2:1 for preactivation for 2 hours. in N 2 Under the atmosphere, at a heating rate of 10°C / min, activate at an activation temperature of 400°C for 40 minutes, pickle and wash with water until neutral, dry to obtain bamboo activated carbon, grind, sieve, and control the particle size of activated carbon at 6-10 mesh . Accurately weigh 1.28g of zinc nitrate, add zinc nitrate, 1.5ml of distilled water and 2ml of glacial acetic acid into 15ml of absolute ethanol under stirring to form solution A; add 10ml of tetrabutyl titanate into 30ml of In water and ethanol, stir for 1h. Then slowly drop in solution A at a rate of 2 mL / min, and continue stirring for 30 min after the addition to fully react to obtain a sol. Then add 15.6 g of 6-10 mesh granular clean activated carbon, stir vigorously for 1 h, soak for 24 h, filter, a...

Embodiment 2

[0030] Accurately weigh 1.68g of zinc nitrate, add zinc nitrate, 1.5ml of distilled water and 2ml of glacial acetic acid into 15ml of absolute ethanol under stirring to form solution A; add 10ml of tetrabutyl titanate into 30ml of In water and ethanol, stir for 1h. Then slowly drop into solution A (2 mL / min), and continue to stir for 30 min to obtain a sol. Then add 15.6 g of commercially available 6-10 mesh granular activated carbon, stir vigorously for 1 h, soak for 24 h, filter, and wash several times with absolute ethanol and deionized water. The loaded activated carbon was dried at 120 °C for 2 h, and then calcined at 450 °C for 2 h to obtain activated carbon supported doped Zn 2+ / TiO 2 Photocatalyst, the photocatalytic degradation rate of the obtained photocatalyst to toluene is 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com